Machining centre with 4 simultaneous interpolating axes and fully automated control.

A job, a performance

The ideal machining centre for those who don’t want to compromise on performance, repeatability and precision. A reliable, safe partner for your production, it performs drilling operations, for stock removal and flow drill, milling of aluminium profiles, light alloys, plastics and steel with limited thickness. Available with an X-axis working range of 4,000mm, 6,700mm, 9,000mm, and, on request, in customisable lengths to suit specific needs.

The processing unit is composed of a mobile portal equipped with a spindle, and is driven by a rack encoder geared motor; it slides on two precision guides fixed to the frame. The mobile portal has a similarly mobile guard which reduces the environmental noise impact, in addition to shielding the operator against possible chips.

The mobile portal controls the positioning of the clamps in the positions determined by the operator program.

Electric spindle S1/S6 10Kw/12Kw up to 24,000 rpm with ISO30 quick coupling, air-cooled. Suitable nominal torque speeds ensure high precision machining and finishing. The encoder very easily communicates with the Numeric Control, thus allowing accurate control of the torque, speed and position of the shaft and tool.

The tool is lubricated with minimum oil diffusion, managed directly by the numeric control, which allows suitable lubrication while at the same time keeping the piece clean.

Sliding of the 3 axes on linear guides with recirculating ball bearings. Movement of the X and Y axes on the precision rack. Vertical movement (Z-axis) on ball screw and ball nut.

X-axis: feeding speed from 0 to 80 m/min.

Y-axis: feeding speed from 0 to 60 m/min..

Z-axis: feeding speed from 0 to 40 m/min.

A-axis: rotation ± 95° with speed 50°/sec. All axes have an absolute brushless geared motor: they do not require resetting after start-up or emergency stops.

Thanks to the broad range of options and possible customisations, the machining centre can be equipped with all necessary tools to facilitate and speed up all types of production.

For the highest level of automation, see the Loaders and Unloaders section.

The operator panel is mounted on a mobile support. The user interface is a 15″ colour display fitted with USBs for remote interfacing with PC and NC, complete with pushbutton panel. Mouse, keypad and pendant control available on request. The NC manages the positioning and blocking of the clamps along the X-axis: this is possible along the entire effective length of the X-axis when the operating mode is set to single zone; or along the two work zones if the pendulum mode is selected.

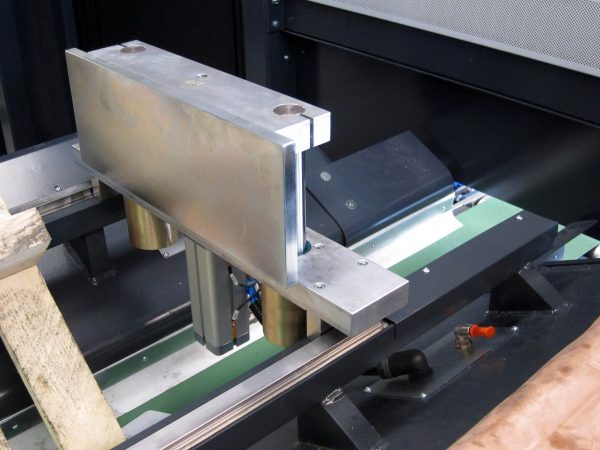

Pneumatic clamping units with low/high pressure system. Positioning is managed by the mobile portal and controlled by the NC at positions pre-set by the operator. The number of clamps varies depending on the type of machining and length of the machine. On request, the RMC machining centre can be ordered without clamps or with hydraulic clamps.

The positioning of the clamps is managed by the NC using a linear module with absolute brushless motor, which allows movement without any intervention by the carriage: the clamps not needed for the current cycle are moved out of the way without interrupting machining.

For total positioning autonomy, each clamp can be equipped with a brushless motor allowing autonomous unloading/release of the piece when machining is complete.

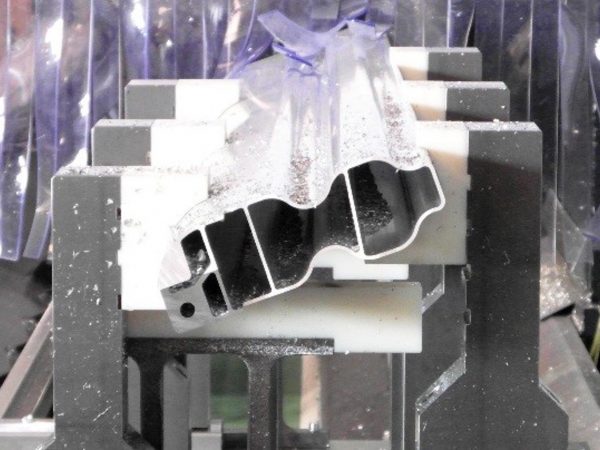

For the machining of profiles that have already been processed or bent, or to allow special machining, a clamping jig can be included customised to suit client needs. Multiple jigs can be arranged, with one for each work area, to increase efficiency. For differentiated production, the jigs can be removed to make space for the traditional clamps.

The mobile portal has a special casing with a sliding and shaped opening to allow longitudinal sliding with respect to the profile being processed. The casing protects the operator from any shavings and also allows improved extraction of the lubrication fumes, in addition to reducing the acoustic-environmental impact.

For a cleaner, quieter, healthier work environment, it is possible to opt for the total closure of the work area with an integral soundproof cabin. The doors, equipped with inspection panels, are split and each door has its own independent motor managed directly by the NC to allow double-zone machining; the central door guarantees safety during loading-unloading operations.

The integral soundproof cabin with horizontal opening is fitted with motorised and properly counter-balanced sliding doors. The inspection panels allow monitoring of the work zone and prevent the projection of shavings, processing fumes and also shield the noise, thus protecting the quality of the work environment. The doors are controlled directly by the NC and allow machining in single or double mode.

Automatic 20-position carousel – with 40-position option – for automatic tool change management, managed directly by the NC and which allows viewing of the 3 tools involved in the change. Graphic viewing makes it easy to find the requested tool.

Sturdy and rigid stops are mounted at the ends of the machine used for bar alignment. Each stop is driven by a pneumatic cylinder and is the retracting type. It is automatically selected by the machine software depending on the process to be carried out. Central stops are available as an option.