“The machine of reference for prestressed steel bar machining for high-speed railway lines”

EXPERTISE

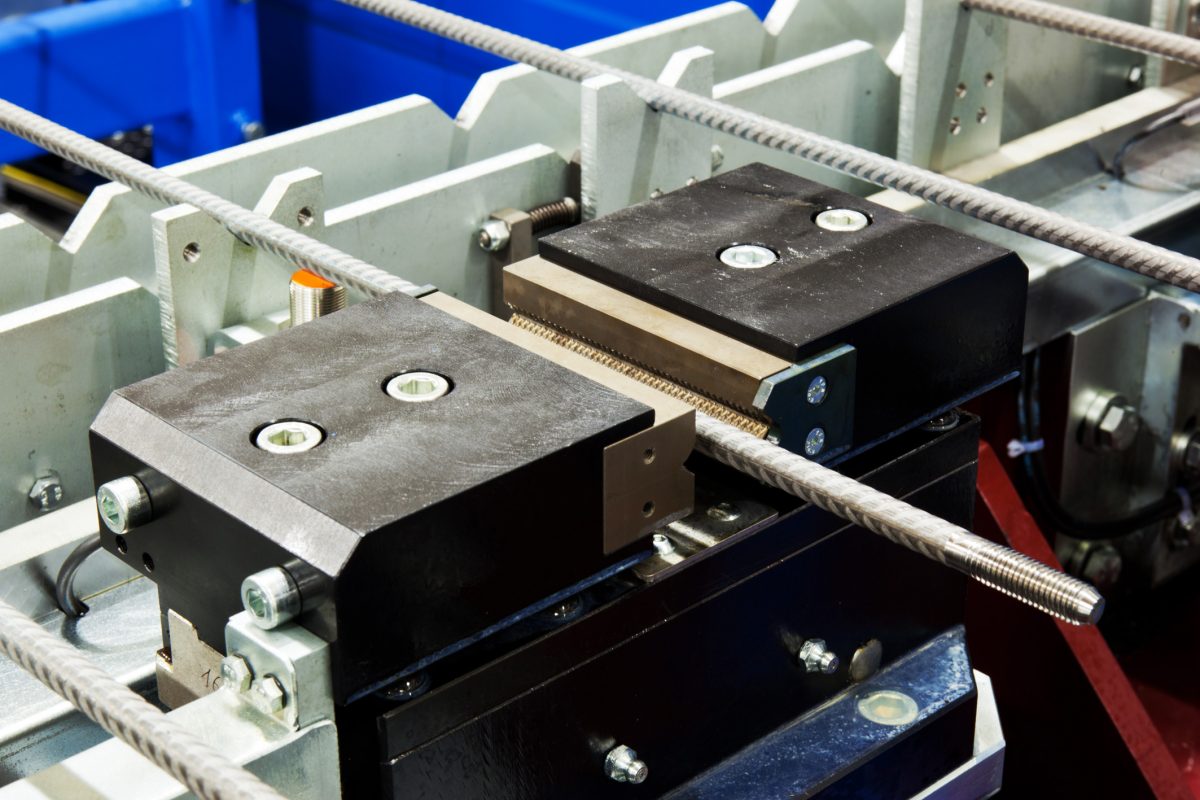

The Ralc Italia line for prestressed steel bar machining is the most widely used machine among steel mills and rod manufacturers worldwide, where it is used to thread prestressed bars used in the construction of high-speed railway lines.

Ralc Italia machines for the production of steel bars are renowned for their reliability and high performance in terms of volume and precision.

They have been chosen by some of the world’s major steel mills over the years, often on more than one occasion, due to the reliable performance, continuity and quality machining guaranteed by these machines. Moreover, a series of measures implemented throughout the course of its evolution have made the bar line a truly highly specialised industrial line.

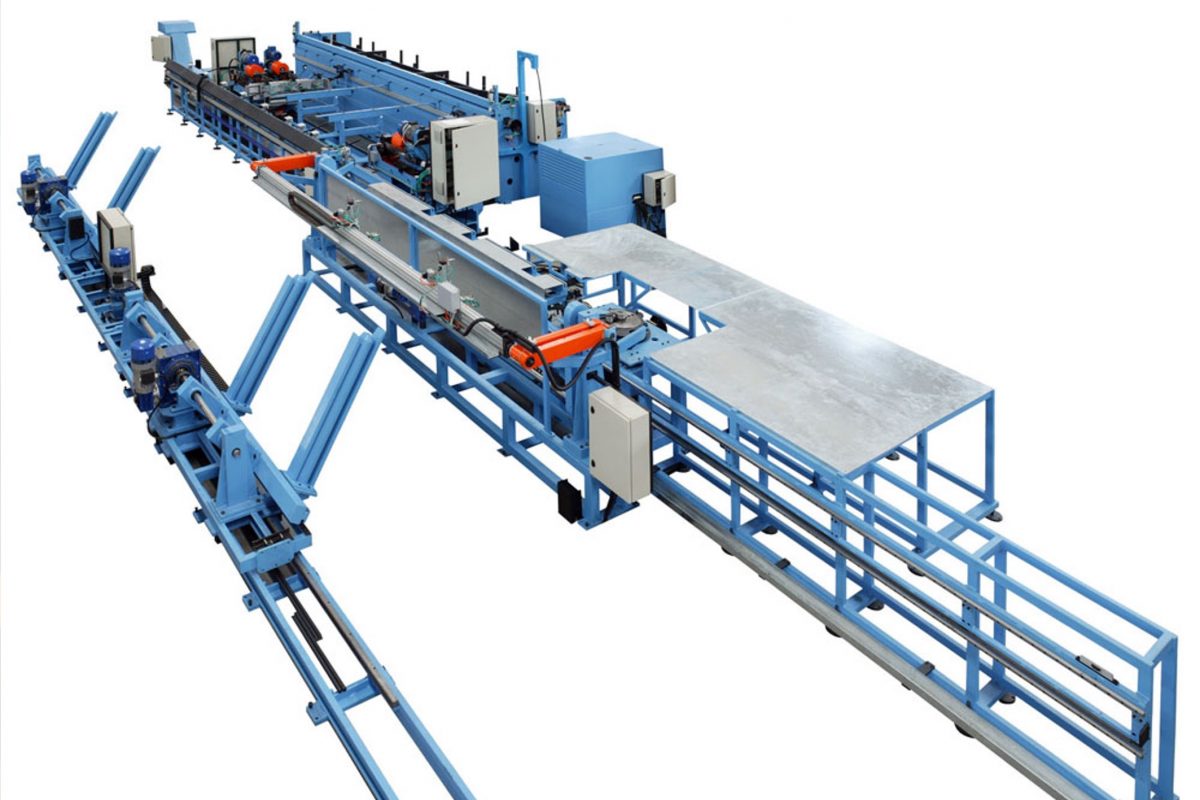

The bar lines are available for both straight and curved bars.

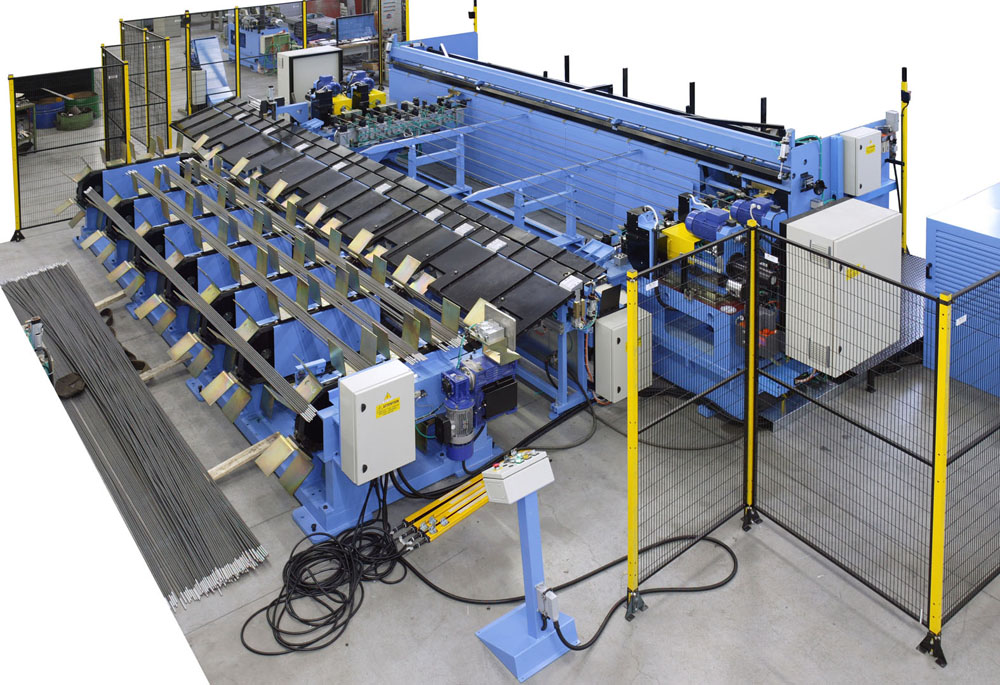

The Mannaino (“Guillotine”) automated loader is a widely tested solution, ideal for lines with a high production of products such as bars. It guarantees continuity and reliability.

Thanks to the separator cylinders dividing the different work sections, it is able to manage three bundles of bars at the same time, with one being processed and the other two in standby, thus eliminating line stops for loading.

The loader progressively separates the bar from the rest of the bundle, making vertical movements.

The loader is fitted with all safety and emergency devices required by law.

A practical solution for dividing machined bars into bundles, ready for strapping.

A practical cradle system collects the bars. When the number of bars set on the panel is reached, the cradles advance by one step. This allows easy strapping and unloading.

A robotic system supplied by Ralc Italia, allowing the easy palletization also of bent bars, positioning them in a dedicated collector.