For the punching of manifolds with or without edge forming, available with one or two axes. Hydraulically operated.

Safe, reliable and versatile

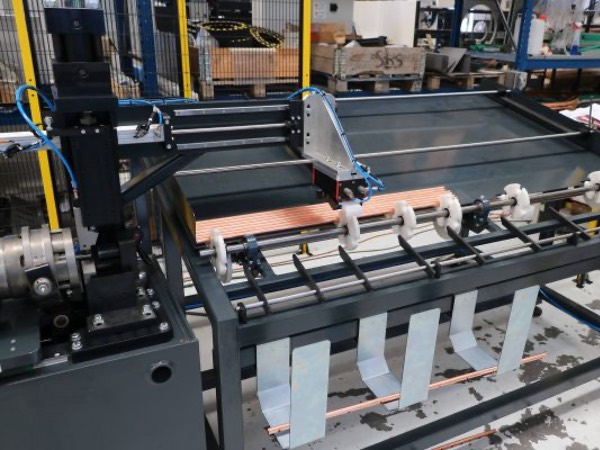

Solid and sturdy punching machine, guaranteed durability, precision and reliability. In the 1AX version it makes holes on one axis in a position settable from the panel; the 2AX version also rotates the pipe, allowing flexible punching on two axes. Pipe loading is manual, but automatic loading and unloading is available as an option. A drilling machine can be integrated, which works in an alternate and synchronised manner with the Primatech.

Every nut, screw, guide, or electrical, pneumatic and hydraulic component are suitably sized, studied and mounted with utmost attention to detail. Nothing is left to chance to obtain a line offering high performance, precision and repeatability. The punching system is the result of careful planning and many years of technical experience, and, if properly equipped, can be adapted to the broadest range of operating conditions in terms of diameter, thickness and length.

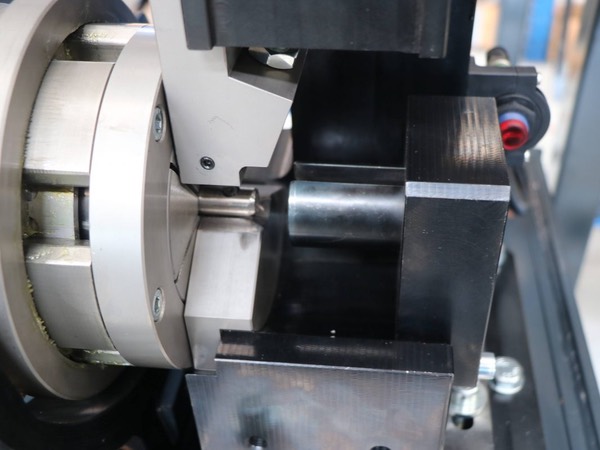

Punching occurs from the inside of the pipe by means of a punch and die, creating an edge on the manifold. Using different equipment, or on pipes with a smaller diameter, punching without edging is possible. Tooling for production changeovers is simple and fast. The operator simply needs to insert the pipe and unload it at the end of machining: with a simple click, the line punches in the positions programmed on the panel.

A panel ergonomically positioned on the electrical cabinet next to the line allows intuitive, fast, and extremely flexible programming. It is in fact possible to determine the distance of the first hole from the end of the pipe, the spacing between holes and the position of the holes on the two axes (only in the Primatech 2AX version). A practical visual system guides the operator, showing a preview of the programmed product.

The punching machine can be enriched with options to increase the autonomy and productivity of the line, for example the automatic loading and unloading system. Moreover, additional machining can be inserted such as drilling, to obtain maximum flexibility and a finished product.

A gripper inserts the pipe and extracts it at the end of machining. For unattended production.

Synchronised with the Primatech, it performs drilling for stock removal alternated with punching and edging. The manifold is finished.

Performs flow drilling alternated with punching and edging, to obtain a finished manifold.

Ideal for the fabrication of manifolds in the refrigeration sector.