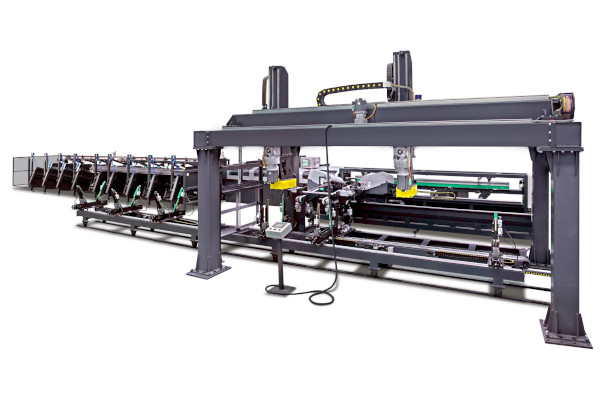

Fully automatic circular saw pipe cutter for straight cutting of pipes, profiles and bars.

Maximum performance, maximum precision

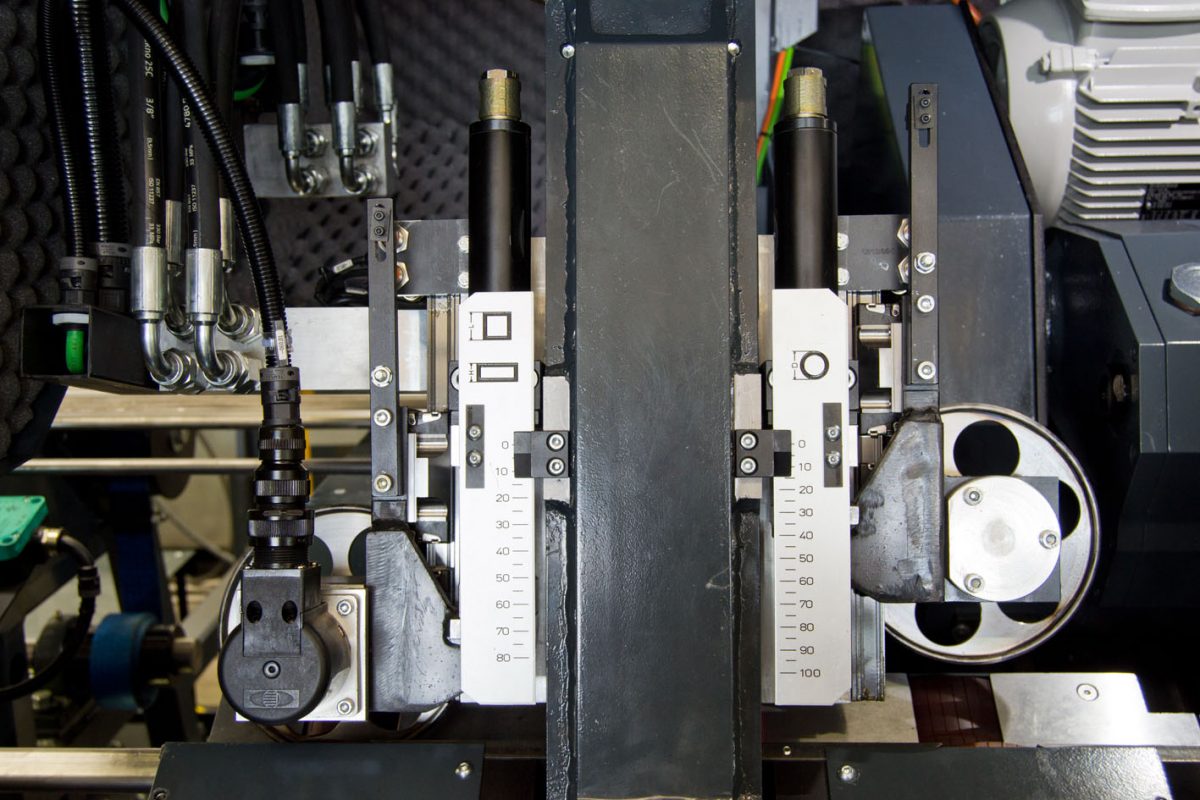

The Aries sawing machine is recognised as the TOP of the range among the pipe cutters currently available on the market. Designed to achieve best performance for cutting lengths greater than one metre, it has a sturdy structure and particularly accurate mechanics, which together with leading-edge software make this not only an extremely high-performing sawing machine, but also an especially precise one.

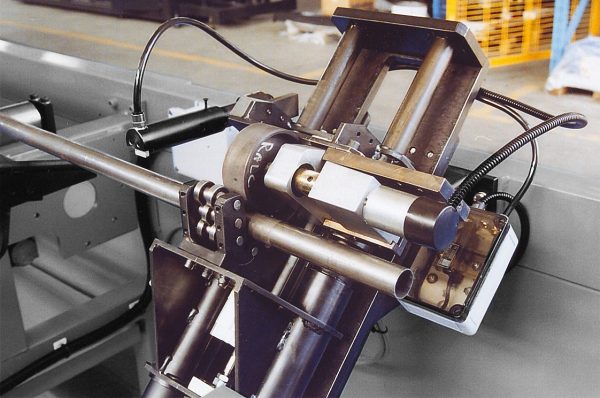

Aries can be used for the traditional cutting of round, square, rectangular, and oval pipes. Thanks to the new HM head, Aries can be used not only as a pipe cutter for pipes with medium-low thickness, but also to cut very thick or solid materials, with above-average performance in its category.

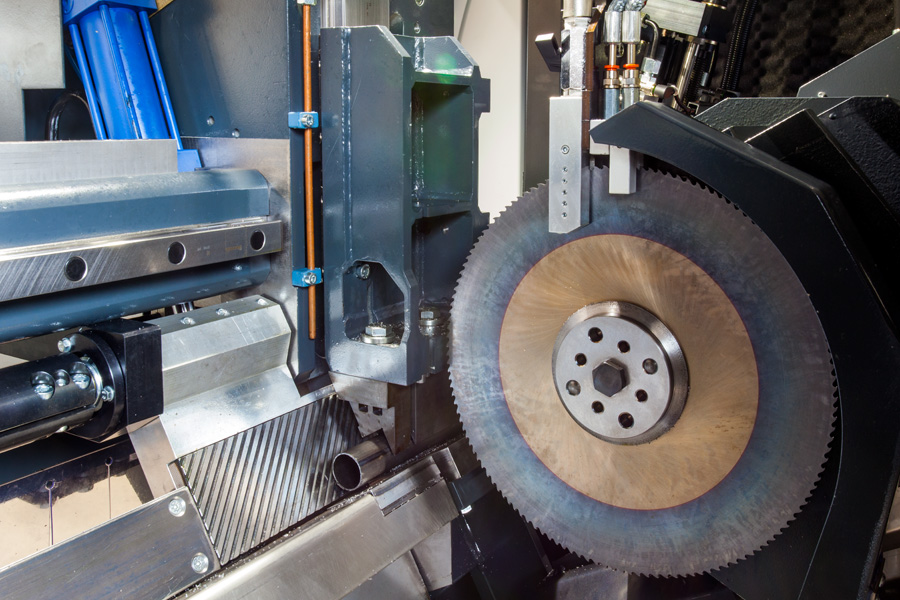

The roll feeding allows positioning of the piece without for stroke repetition, thus making it the ideal feed system for pieces longer than one metre. And while this is the type of production where Aries expresses the height of its potential, there’s no reason not to use this high-production pipe cutter also for shorter lengths, thus making Aries a precious ally for all types of production.

As of now, Aries is available in both the traditional version for cutting materials with medium-low thickness, and in the new HM version for cutting very thick materials or solid bars. In both versions, the sturdily constructed cutting head is driven by a brushless motor and recirculating ball screws, allowing high performance and fully automatic positioning. The machine is supplied standard with minimal lubrication and water/oil emulsion, allowing you to choose the solution most suited to your specific needs.

The touch screen panel is intuitive and practical: programming your work is simple and fast. Up to 4 cutting lengths can be programmed on the one bar, and optimised cutting parameters can be set depending on the material.

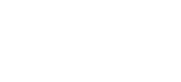

Aries has an integrated loading and unloading system, with modular lengths. The bundle loader allows loading of pipe bundles, thus optimising loading times and facilitating unattended production. The unloader with digital readout acts as a piece sorter, separating good pieces from trims and scrap.

Aries can also be combined with a subsequent machining unit to satisfy production needs increasingly requiring additional operations after cutting to provide the finished product.

Aries is supplied with its own bundle loader for a max. length

6,500mm. Other lengths and customisations are available on request.

External and internal deburring for different materials, diameters and lengths. Modular systems to suit different budgets and production requirements.

A practical, fast and economical solution to remove shavings from inside the pipe. Does not remove machining oils.

Length, straightness, perpendicularity, surface control with piece mastering. Other control systems available on request.

Efficiently removes shavings and machining oils, for completely clean pipes. Available for different materials, diameters and lengths.

Drilling or moulding units can be applied downstream of the cutting operations to perform any ancillary machining necessary to complete the piece.

Allows the pipe to be rotated and position the weld as desired. Available for round and square pipes.

Various solutions are available to suit all types of budgets, production requirements and line configurations.