Single axis machine for the production of straight and non-flanged nozzles for the refrigeration sector.

Fast and economical

Much more economical with respect to a press, the machine used to produce ducts forms the metal in absolutely competitive times with the added advantage of fast and low-cost tooling. It is able to develop ducts directly on the structure of the heat exchanger itself and multiple ducts on the same sheet of metal.

The flanging machine allows ducts to be developed in aluminium and steel.

A small “treasure” at a reasonable price, yet able to achieve excellent results and utmost performance. A safe and reliable machine perfect for the series production of straight, non-flanged nozzles with diameter from 100 to 800mm, and maximum edge height 100 mm. The material is progressively plastic formed by the machine, starting from a perforated sheet metal blank.

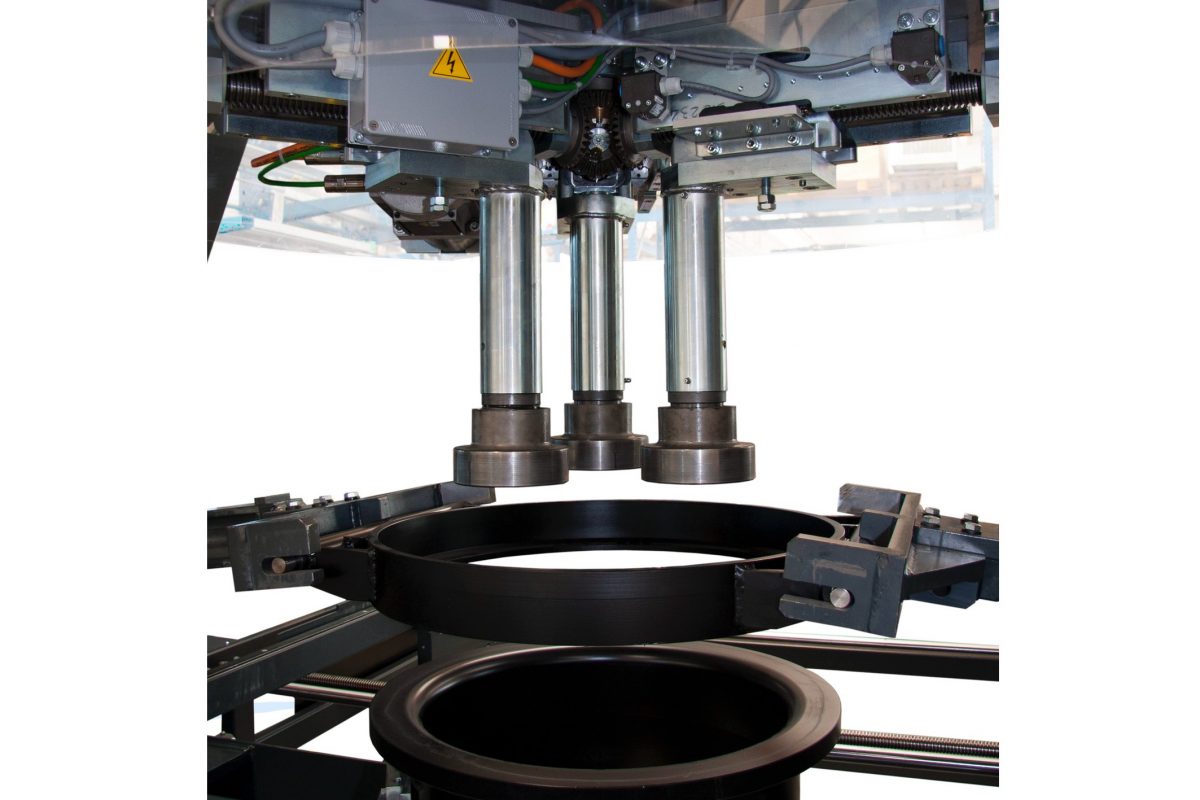

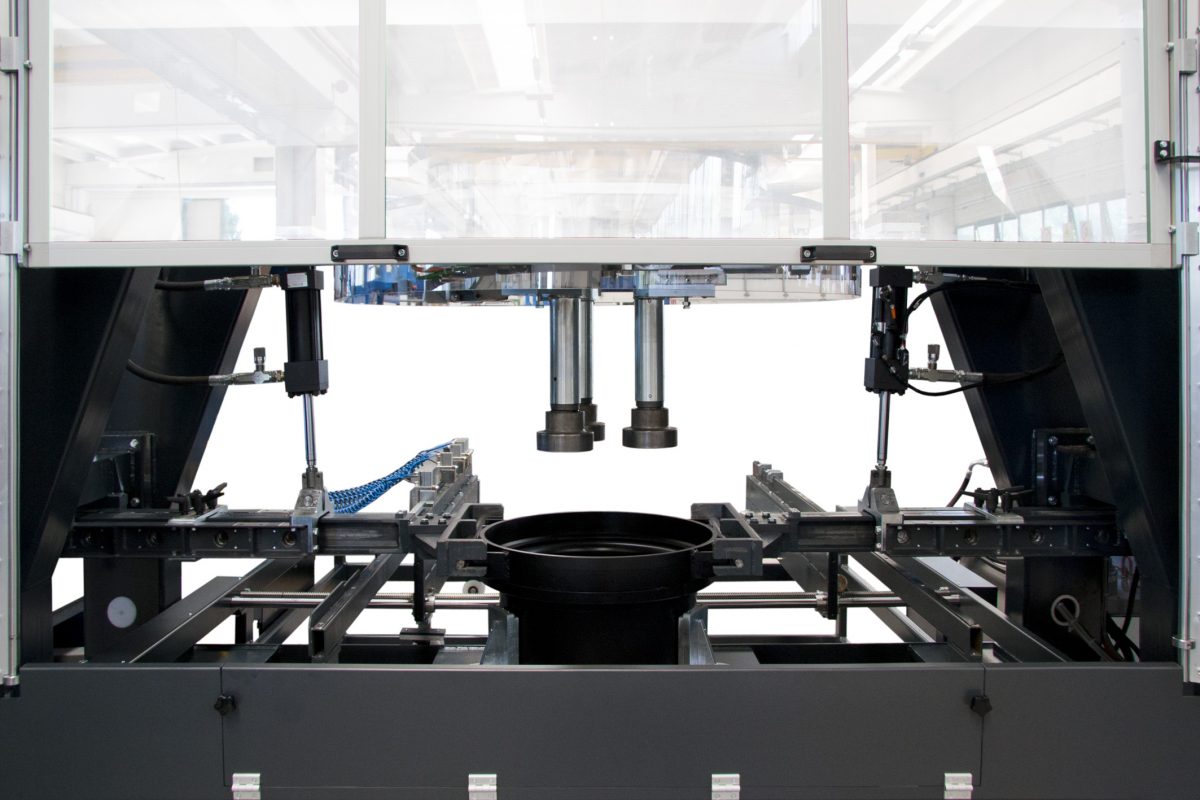

The machine has an arc-welded structure, properly machined by machine tools, which give the system rigidity and stability. The forming roll unit is mounted on the top part of the frame. It is lowered by means of a hydraulic linear actuator and four recirculating ball guides, to eliminate any possible backlash. The rolls are mounted on a plane and connected by means of bevel gears. The range of action of the rolls is managed by the controlled motor, and their rotation by the geared motor with inverter.

The lower part of the structure is where the die-holder is housed, developed in such a way as to optimise tooling times when the diameter changes, and facilitate sheet metal centring by the operator, for which there are two guides with adjustable spacing. A blank holder blocks the sheet during processing to guarantee the best possible quality and finish.

The Ralc Italia flanging machine is supplied standard with everything you need to facilitate the operator and maximise production efficiency.

Quality flanging is possible thanks to a combination of studies conducted on the materials, careful forming calculations, and incredible experience based on hands-on work. Along with the equipment, Ralc Italia also provides the preliminary information to prepare the material, and the complete flanging program, ready to use: the operator simply needs to select the saved program on the control panel and start production.

Each die has a blank holder, which is lowered by means of a hydraulic linear actuator with adjustable pressure; it holds the sheet in place during flanging operations, which is essential in ensuring the quality of the product. In order to optimise the stroke of the actuators and therefore machining times, the blank holder is made to rise up to the maximum height only for the changeover: during production, it stops at a predefined height.

The fully equipped machine for ducts is used to produce ducts with diameter from 100 to 800mm.