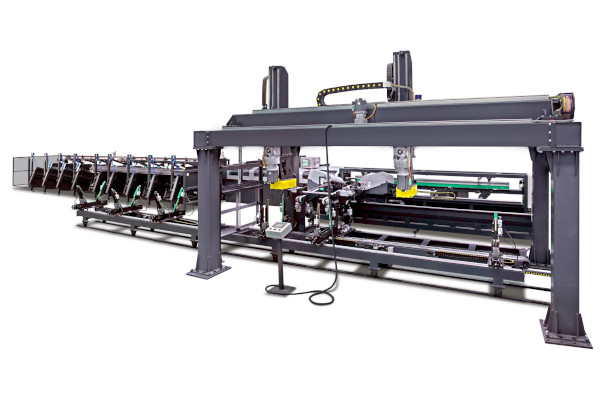

Universal automatic sawing machine for straight cutting of pipes, profiles and bars.

High production, utmost precision

Designed to ensure high production volumes thanks to double and triple multiple cutting, Gemini 100-3 is the perfect combination of power, precision and versatility. It guarantees optimum results in the most varied working conditions: from simple pipes in steel to those in AISI with varying thickness, and even solid bars in ferrous and non-ferrous materials, in addition to being highly efficient on all types of profiles, including those in aluminium.

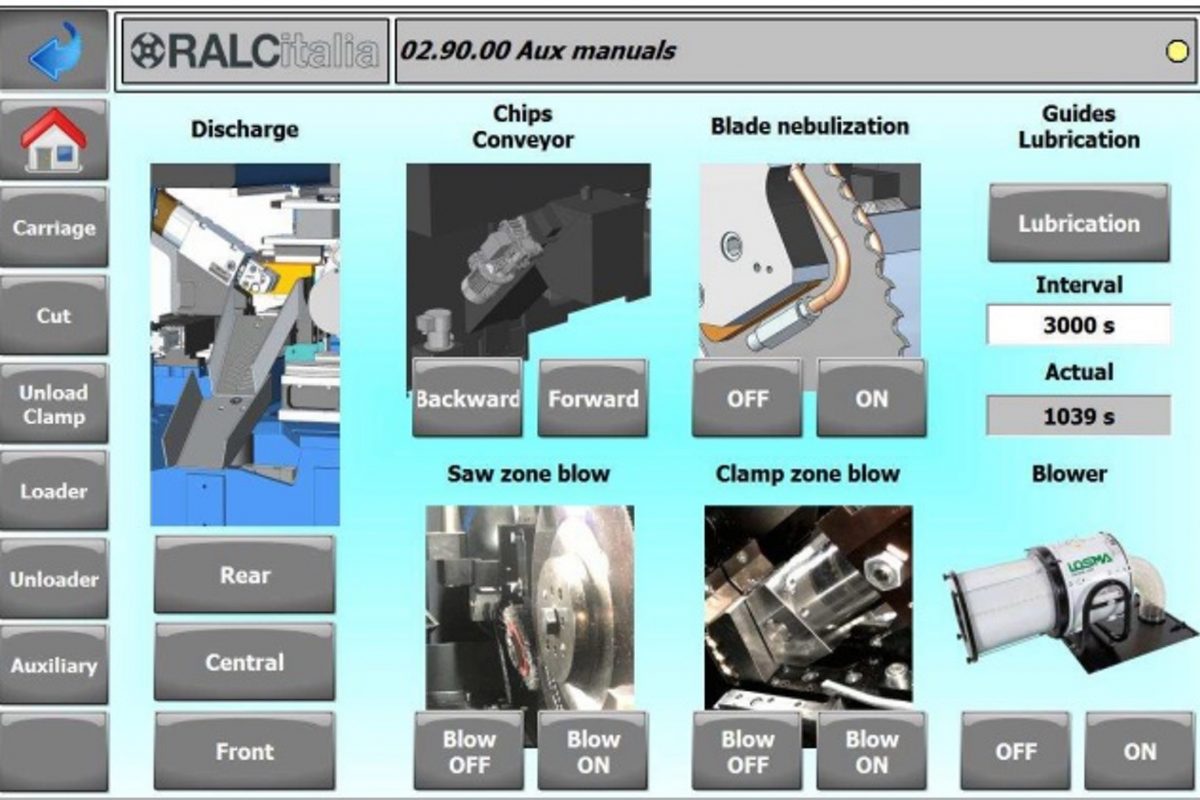

The structure is decidedly sturdier compared to other sawing machines in its category, the adjustable clamping and three controlled axes make it an extremely precise sawing machine, ideal for large series production, but perfectly adaptable for small volumes when needed.

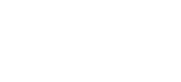

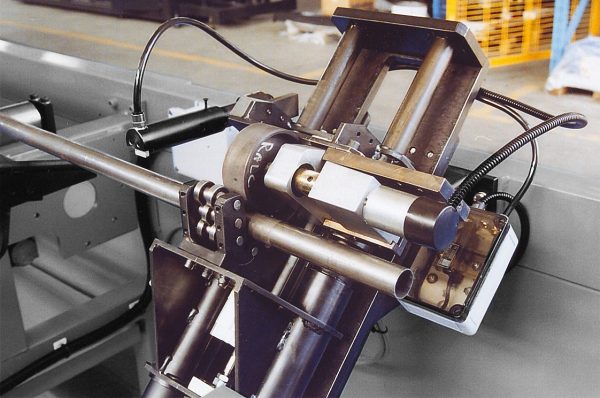

The high-performance cutting head with fully automated positioning allows use of HSS and HM blades and guarantees high-level production for all pipes, bars or profiles in ferrous or non-ferrous materials, whether round, square, rectangular or special.

Gemini 100-3 can be combined with a broad range of automatic loaders and unloaders with modular structure and variable length; moreover, numerous customisations are possible with different levels of complexity, allowing the development of an AD HOC cutting line for every single need.

Gemini 100-3 has a decidedly sturdier and more stable structure compared to other sawing machines in its category, an advantage offering improved long-term precision and performance: the solid and sturdy structure in fact absorbs the vibrations caused by high-speed movements, improving not only the precision and quality of the cut, but also the life of the blade.

The software allows a maximum of 4 lengths to be programmed on the same bar, thus reducing waste. The automatic unloader separates the four different lengths from the scrap.

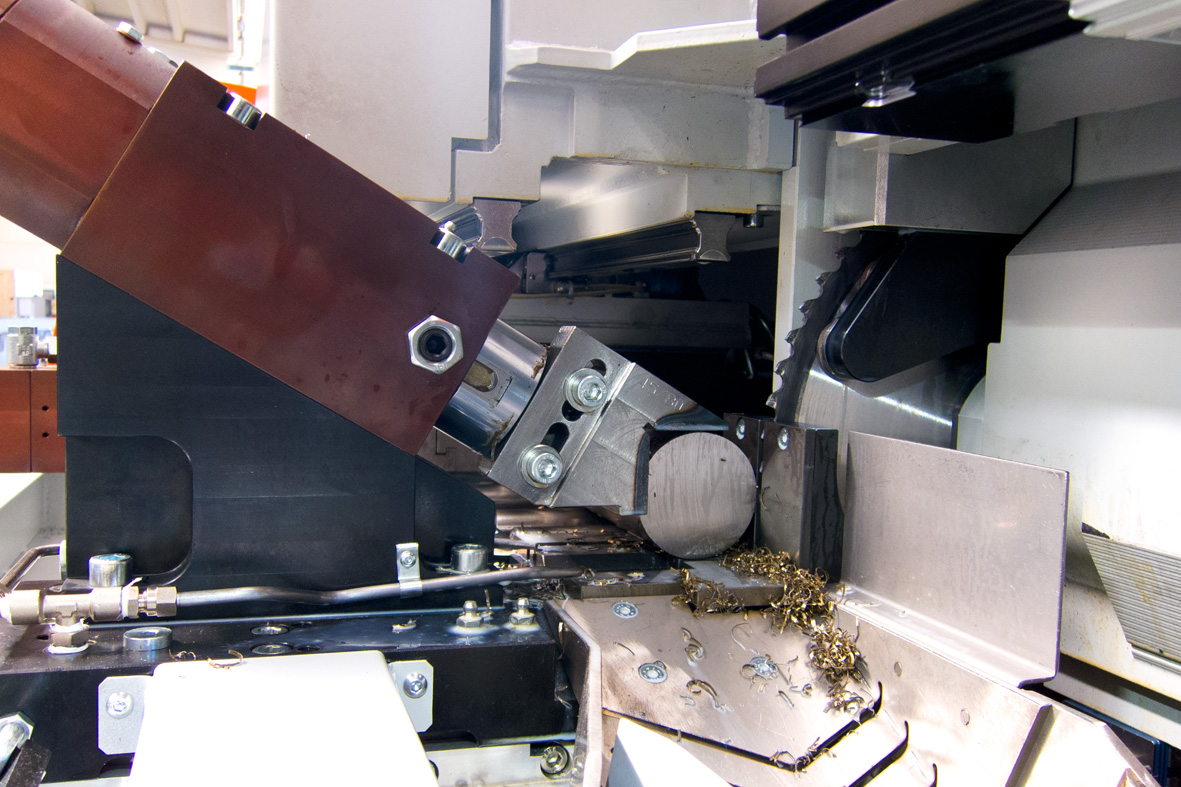

Thanks to the use of numerous images and self-explanatory graphics, the touch screen operator panel acts as an efficient guide to machine programming. The program save functions allow the different recipes to be saved, thus lightening the workload of the programmer and improving the efficiency of the system.

The automated production process is not limited to just cutting, but rather extends to numerous other processes: the possibility to integrate various types of controls, deburring or washing into the cutting line, not to mention marking or drilling, exponentially increases the automation of the production process, reducing costs and handling times and thus increasing the commercial value of the finished piece.

The software package can be completed with an optional Industry 4.0 package, which can be customised according to need: production monitoring, predictive maintenance, integration with company systems are just some of the possible solutions.

External and internal deburring for different materials, diameters and lengths. Modular systems to suit different budgets and production requirements.

A practical, fast and economical solution to remove shavings from inside the pipe. Does not remove machining oils.

Length, straightness, perpendicularity, surface control with piece mastering. Other control systems available on request.

Efficiently removes shavings and machining oils, for completely clean pipes. Available for different materials, diameters and lengths.

Drilling or moulding units can be applied downstream of the cutting operations to perform any ancillary machining necessary to complete the piece.

Allows the pipe to be rotated and position the weld as desired. Available for round and square pipes.

For piece traceability or to facilitate subsequent processes with coding. Engraving and percussion, laser or ink marking is available.

Various solutions are available to suit all types of budgets, production requirements and line configurations.

The high productivity of Gemini 100-3 makes it ideal for industries requiring high hourly production rates, such as the automotive and moulding sectors.