“Repeatability, performance and reliability. With 4 or 5 axes.”

EXPERTISE

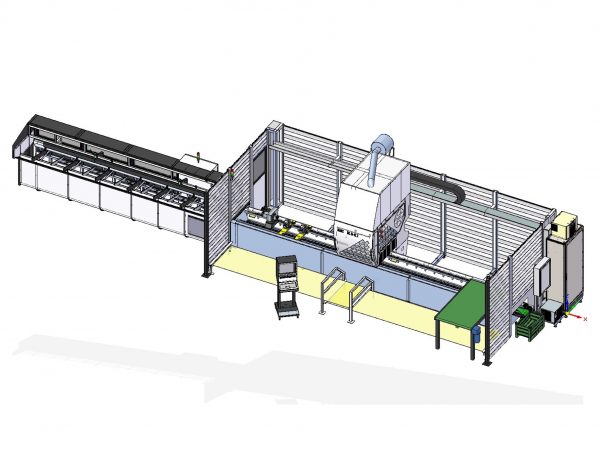

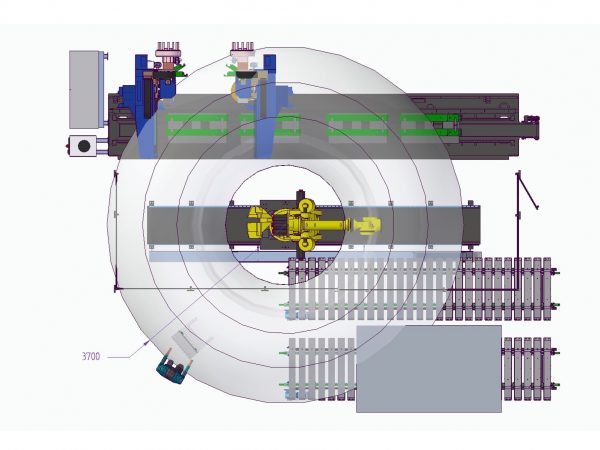

Designed for purely industrial use, Ralc Italia machining centres are available in modular lengths which can be used either as a single working zone exploiting the entire length, or split into two zones for use in pendulum mode, with continuous loading and unloading of the pieces. Moreover, they can be equipped with automatic and modular loading and unloading systems, combined with robotic solutions or inserted in work cells complete with bending, punching, or other systems.

They are available for aluminium, but also for steel, stainless steel and copper, and are ideal for machining round, square, rectangular, hexagonal sections and extruded profiles of all kinds.

All Ralc Italia machining centres are equipped with fully interpolating and absolute axes, and do not require resetting after machine start-up or emergency stops.

One distinctive feature of Ralc machining centres is the possibility to be equipped with automatic loading and unloading systems, similarly modular, constituting an efficient alternative with respect to the classic pendulum mode. These allow increased automation, while significantly reducing operator input times, thus overcoming one of the main limits of traditional machining centres.

The ideal solution for all types of profiles, it practically and efficiently solves the problem of loading more or less irregular sections. Featuring modular depth and also usable with standard sections, it can be equipped with a pre-loading system to guarantee continuous production.

Ideal for small and medium production batches, can be equipped with a pre-loading system to further speed up the preparation of the material. Economical, versatile and efficient.

Designed for large batches and mass production. Loading the entire bundle guarantees the maximum autonomy of the line. Robust and versatile, it can be enriched with multiple options, which can be selected according to production needs.

Allows the loading and separation of bundles of special profiles, automatically orientating them when necessary for the desired cut. Unique to their kind, they minimise the necessary operator input for loading and increase the line’s unattended production time.

Economical, practical, versatile, it allows machined pieces to be unloaded in a collector in no specific arrangement.

Practical, flexible, allows unloading of the machined piece, as well as its orderly arrangement without any impact that might ruin its surface. Lastly, it can be used to load pieces and thus improve efficiency with respect to the traditional pendulum operating mode.