Orbital cutting line, fully automated, for cutting pipes with limited thickness in copper, aluminium, steel and cupronickel.

Long-standing tradition, maximum reliability

The orbital cutting line is characterised by a sturdy structure and particularly precise mechanics. The small and large features of this machine are the product of decades of experience in building this type of line, and are precisely what sets it apart from other lines available on the market, thus making it a safe and reliable choice with guaranteed precision, and chipless cutting. It is available with one, two or three lanes to provide the perfect solution for all production needs.

Coil or rod? Orbital cutting!

Whether working from a coil or straight bar, the orbital cutting line is the ideal solution for chipless cutting. Orbital pull-apart cutting is carried out with minimal adjustable lubrication, properly conveyed inside the machine to keep the work deck clean. Production changeovers are extremely simple and fast. Thanks to the modular unloading systems, it is possible to cut either long or short pieces.

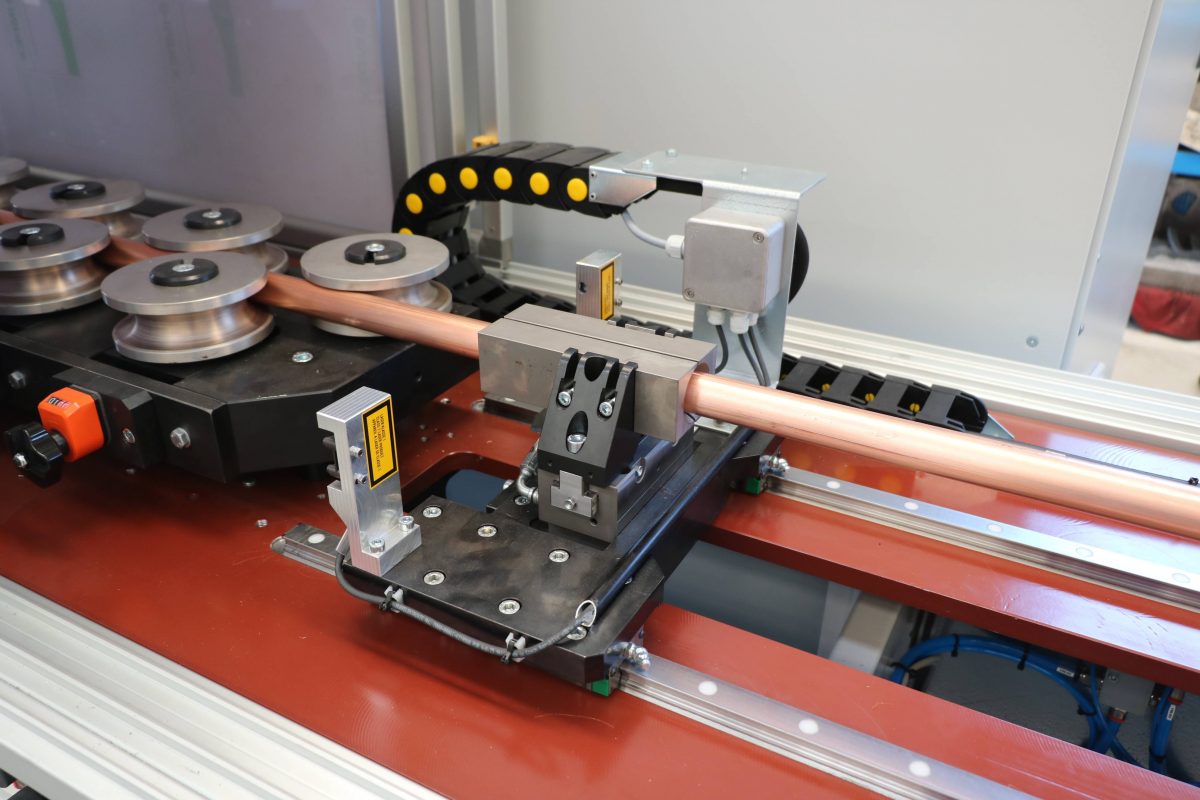

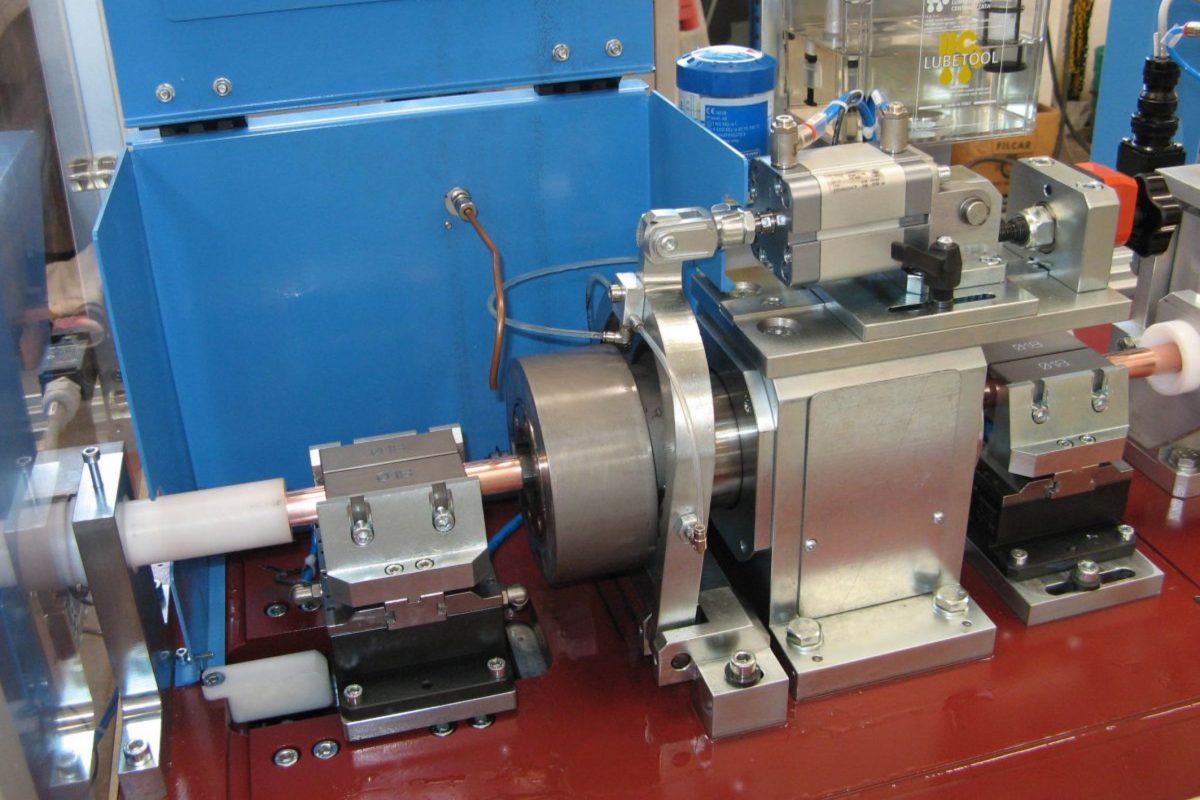

In the coil version, the line includes two consecutive straightening units, vertical and horizontal, with 5 or 7 rolls. In the version for straight bars, the pipe is fed directly into the feed unit, available with belt or gripper: the advantage of belt feeding is that stroke repetition is not required. Clamp feeding on the other hand allows a reduction in the final waste.

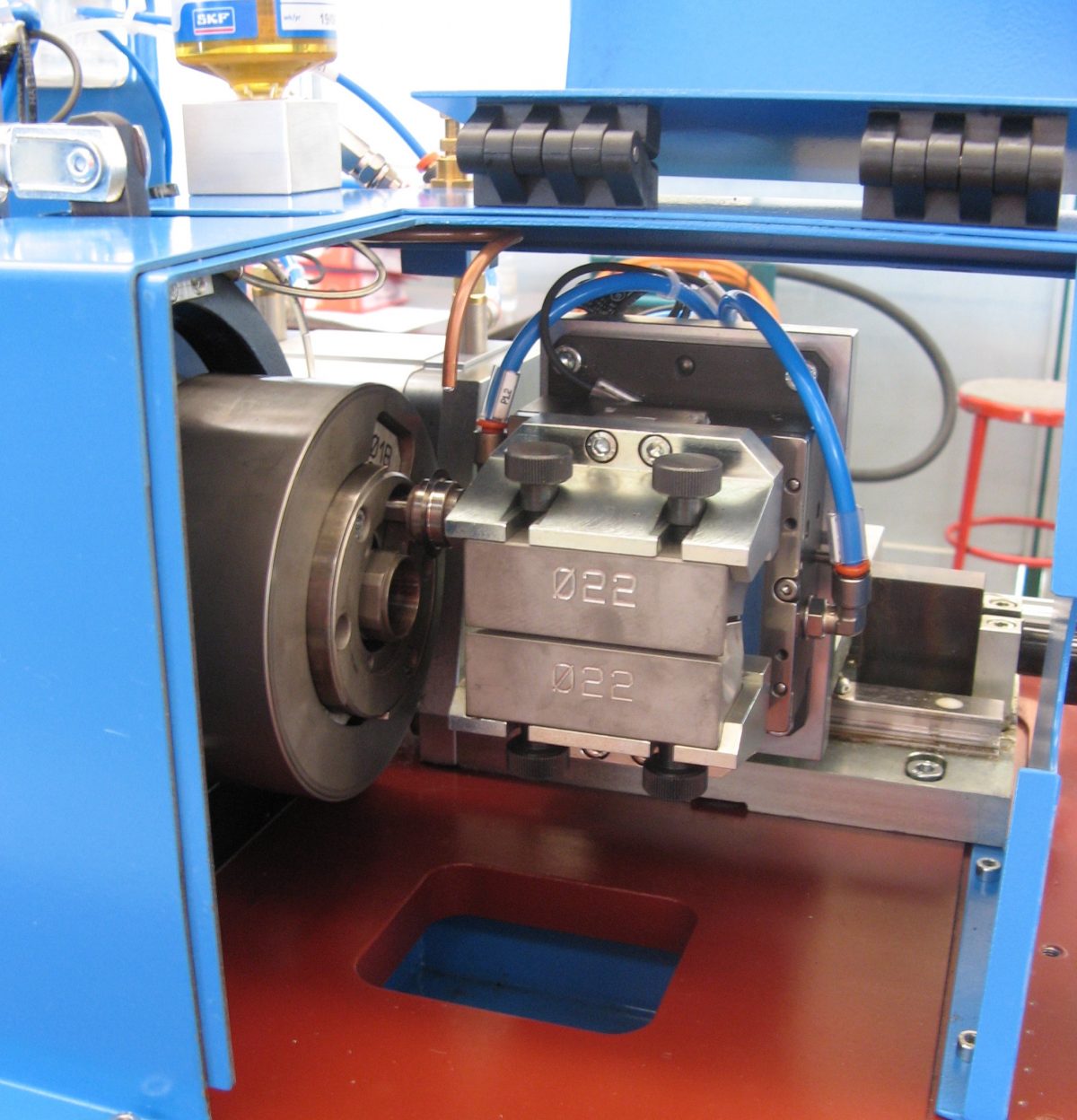

The pipe is blocked by a clamp and tensioned before cutting. The knife makes an orbital movement and the pipe is pre-cut, then tensioned again; this movement separates the two parts. The control panel can be used to set the number of pieces to be produced, their length and the cutting parameters depending on the type and material. The machine automatically stops when the set quantity is reached.

The difference is in the details, and the details make the orbital cutting line perfect for the application in which it will be used.

Thanks to the integration of additional applications, production times can be optimised, thus eliminating the cost of secondary machining and reworking of the piece on different lines.

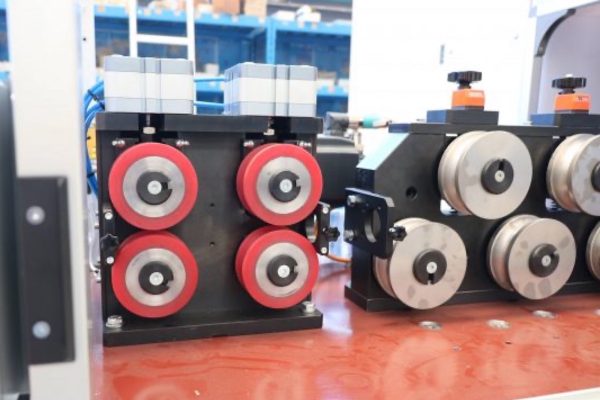

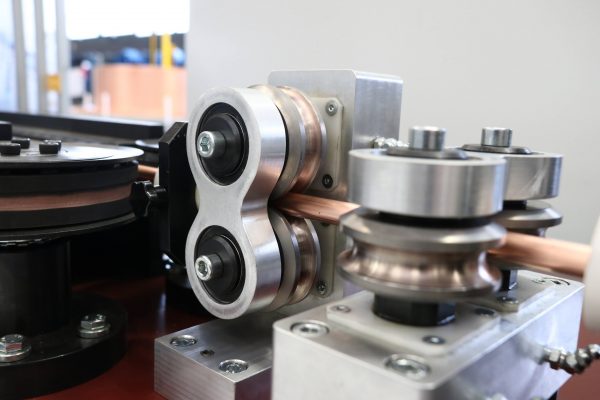

A pair of motorised twin rolls to facilitate pipe feeding into the cutting line.

These work on a vertical and horizontal plane and guarantee the roundness of the pipe along its entire length.

Carries out simple in-line belling processes. A unit with rotary tool can be included for the spherical closure of the pipe.

Available with 2 to 6 steps, one of which with rotary tool. Can be disabled for the production of only cut pieces.

The line includes a series of remote assistance systems. Moreover, it can be supplied with 4.0 interfacing, which can be customised to suit the client’s needs.