Machine for hemispheric or flat closure of round pipes.

Small, but also big

The hemispheric pipe end closing machine for copper and aluminium is designed for the solar sector: compact, economical, simple to use. Using a specific tool, a flat closure can be applied to the pipe for various applications. It can be integrated into work cells and it can also machine punched pipes.

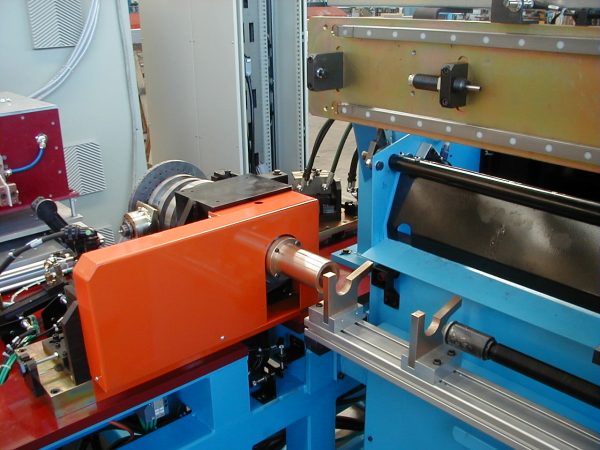

The induction pipe end closing machine for steel is a highly technological machine used mainly in the furniture components sector, and is available in versions for hemispheric and semi-flat closure.

All Ralc Italia pipe end closing machines are designed to guarantee total reliability and maximum line availability, hence why they have been chosen by the best industry specialists. They are fitted with safety devices in accordance with the machinery directive and equipped with highly intuitive control panels, which assist and guide the operator in all operations. They are supplied with a detailed use and maintenance manual, complete with wiring, pneumatic and any hydraulic diagrams.

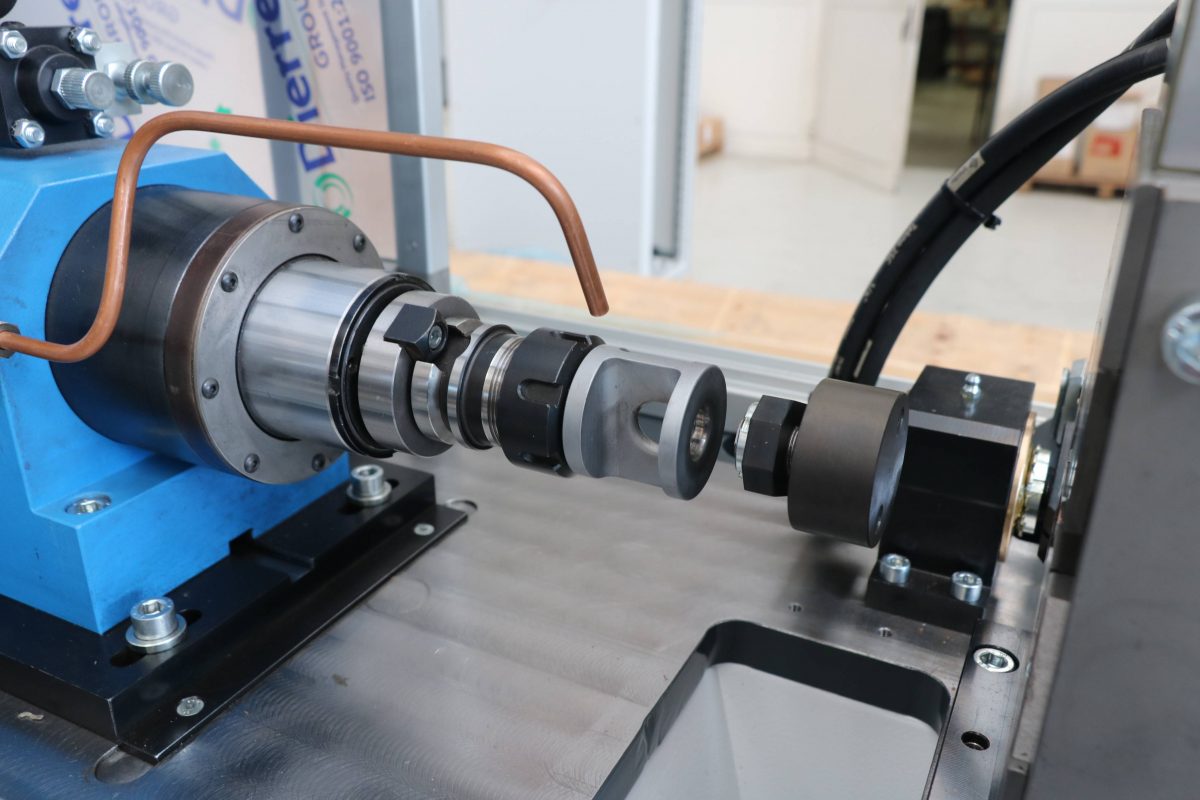

The standard line is supplied with manual pipe insertion by the operator. The operation is simplified by the presence of a mobile stop. When positioned, the clamp closes the piece and a linear feeder feeds the tool in line with the pipe. Hemispheric forming occurs by means of friction: in contact with the pipe, the rotary tool heats the material and forms it thanks to the specific shape of the tool. Other types of forming are possible with specific equipment.

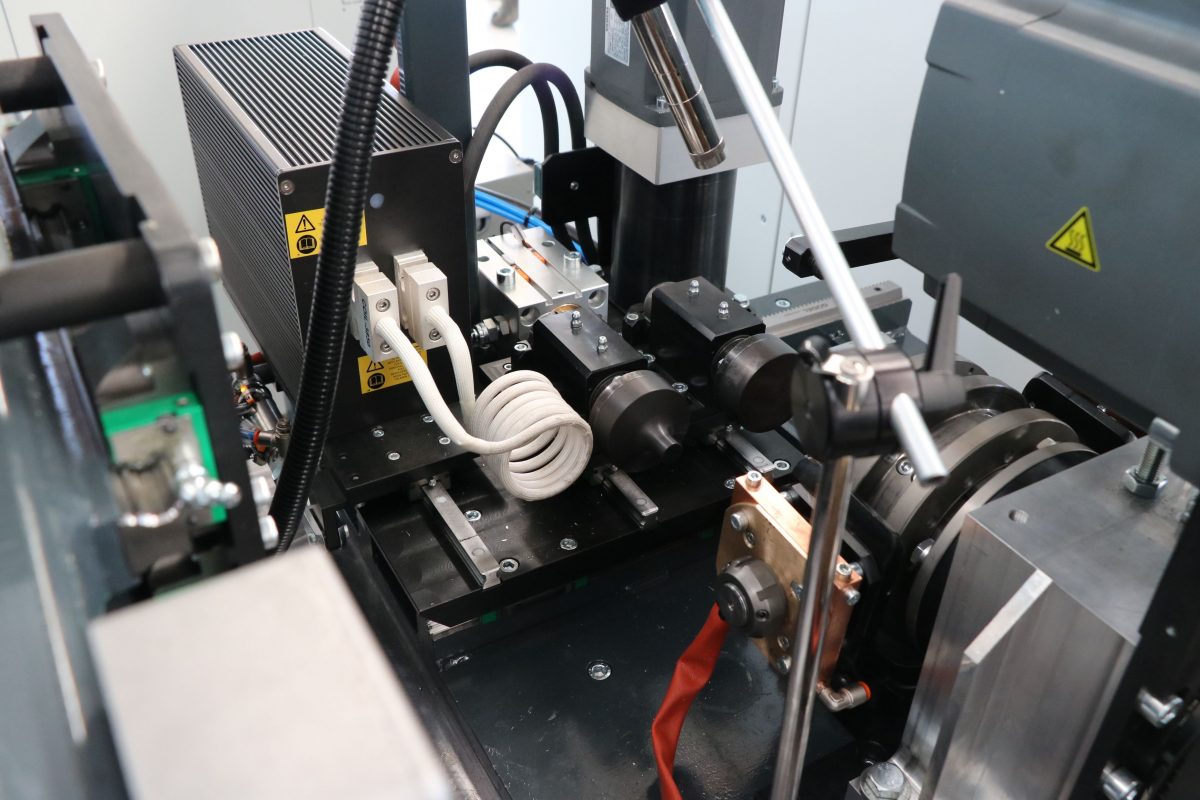

Designed for materials requiring significant heating, when suitably equipped it can perform hemispheric or semi-flat closures. In-line machining of both pipe ends is also possible, thus avoiding any re-handling. The piece is closed by the hydraulic self-centring clamp, a linear feeder brings the inductor into position and then retracts it so that the dedicated tools can carry out the necessary forming.

Induction pipe end closing machines are equipped with automatic loading and unloading systems.

The pipe end closing machine for copper is supplied with manual loading, but can also be supplied with automatic loading and unloading as an option. It can also be integrated into machining cells, for example downstream of an orbital cutting line or in multi-step end forming machines, in turn located upstream of other machines.

Maximum loading capacity and excellent separation of the pipe from the bundle. For high production and autonomous transfer.

Complete with positioner and linear feeder, to feed the pipe up to the forming head.

A pneumatic drilling unit is available as an option, fitted with a clamp, rapid changeover systems and tools.

Following are several examples of applications in different sectors.

Made with pipe end closing machine for copper and aluminium and rotary friction tool.

Made with pipe end closing machine for copper and aluminium and rotary friction tool.

Made with pipe end closing machine for iron, induction heating and specific tools.