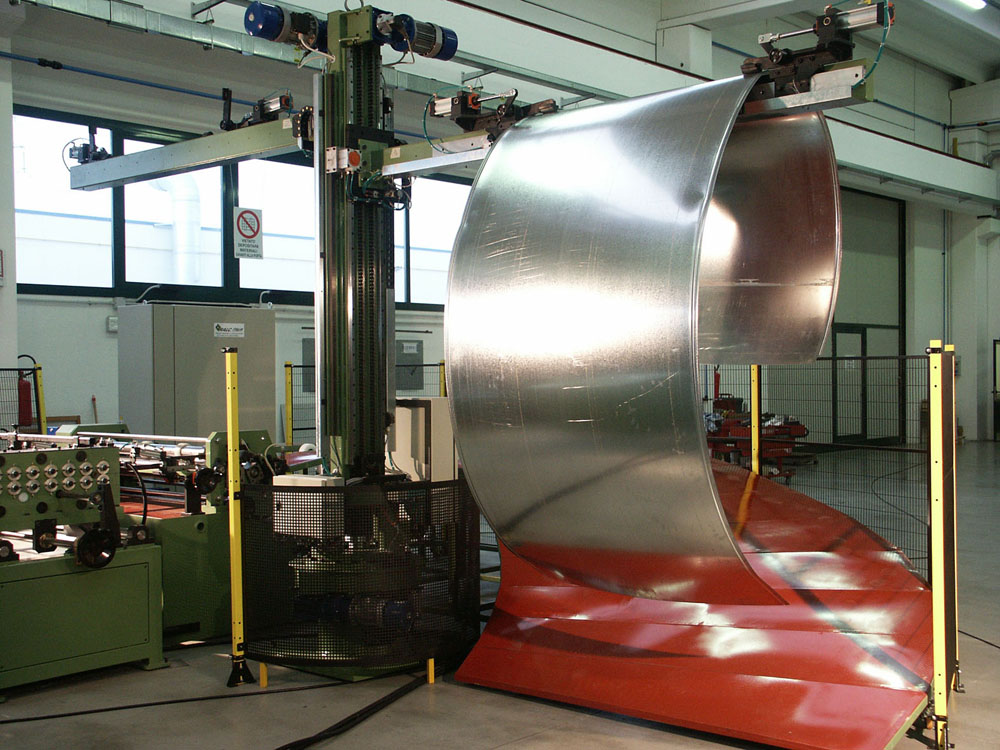

Processing line designed for the profiling and calendering of fan housing backs, equipped with an automated system for the unloading of machined parts.

High specialisation

Sold separately or together with the edging forming line for fan housing sides, the fan housing backs calendering machine is a highly specialised line for the ventilation industry. It allows the automation of complex forming processes, allowing the automatic profiling, calendering and handling of sheet metal blanks, even with large dimensions, in respect of operator safety.

The fan housing backs profiling line offers an efficient and practical response to the need to separate, handle and process sheet metal blanks, even with large dimensions, making it possible to obtain a finished product on a single processing line.

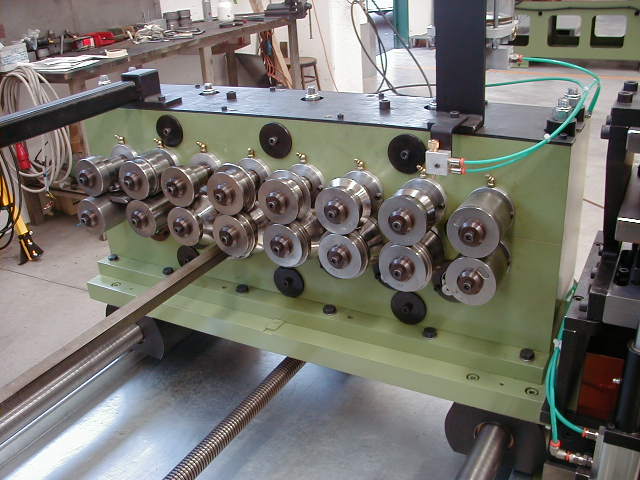

After separation, the sheet metal blank is automatically fed into a profiling roll unit consisting of a fixed side and a mobile side, and adjustable depending on the size of the sheet being processed. The rolls progressively and simultaneously shape the two edges of the sheet. The rotation speed is controlled by a single motor drive. A dedicated system holds and guides the sheet during machining.

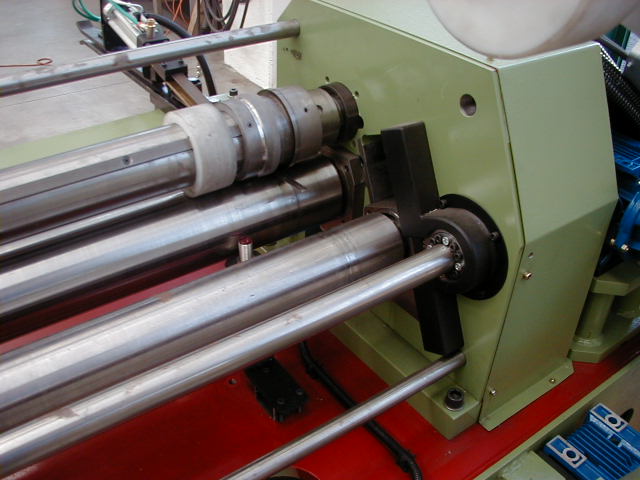

The profiled sheet is automatically fed into a calendering roll unit, which progressively shapes the sheet by means of a controlled motor, creating 4 bending radii.

For automation and separation of the sheet metal blank, and to facilitate safe unloading by the operator.

The line includes a sheet metal loader fitted with side retainers; the mobile side can be adjusted to suit the working dimensions. The separation system, fitted with magnets and suction cups, picks a single sheet from the loader, lifts and feeds it into the profiling rolls.

Thanks to the machining carried out by the fan housing backs line and fan housing sides line, the back and sides can be mechanically coupled without any need for welding.