“When the road rises, you cannot hide.” Eddy Merckx

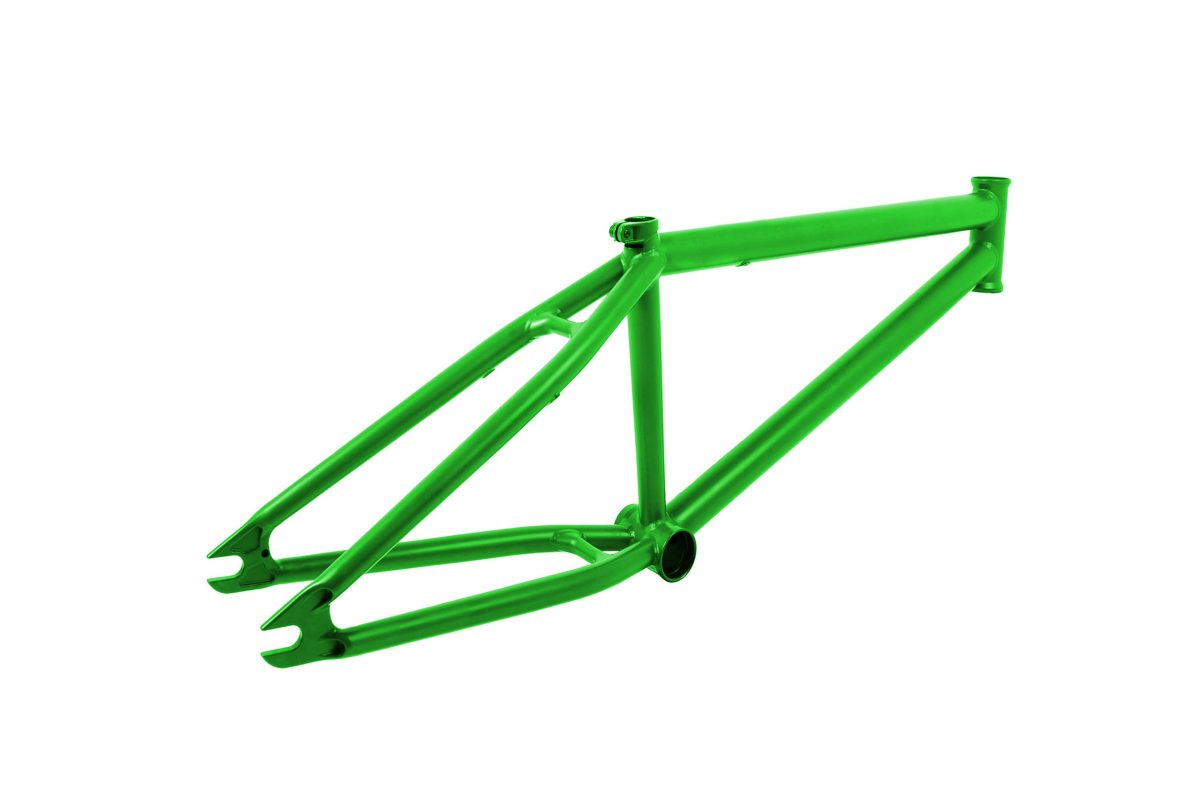

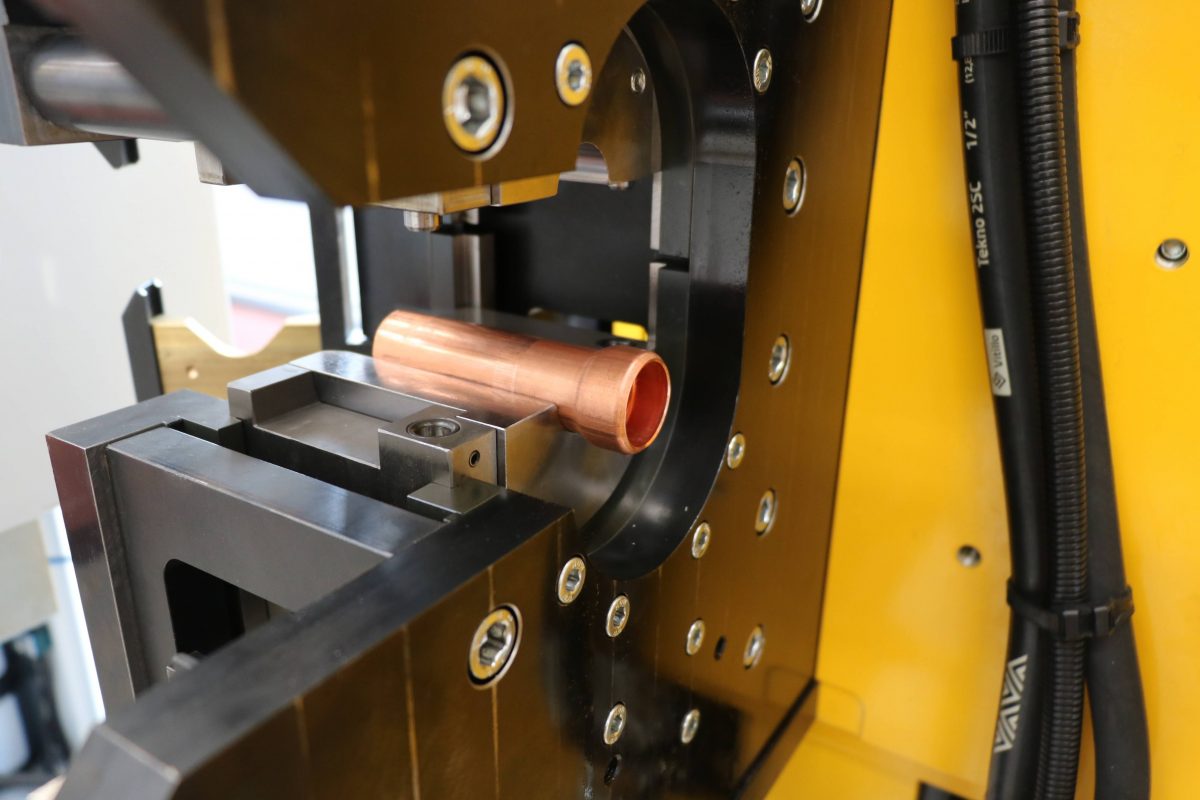

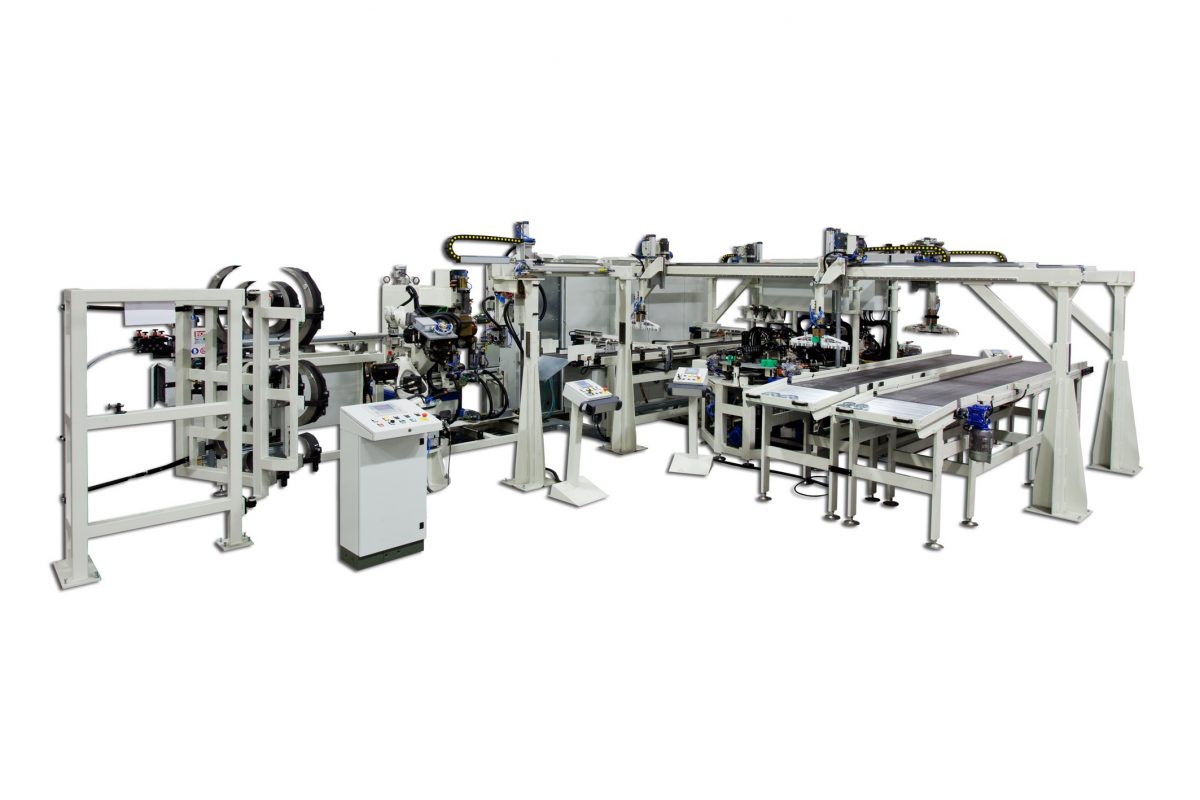

Whether for motorcycles or bikes, whether building a frame or producing small accessories such as bearings, clamps or handlebars, Ralc Italia has all the right solutions for this highly specialised sector, where the accuracy of machining and productivity have the ability to give clients the upper hand.

It’s the details that make the difference in this sector made up of families, enthusiasts and professionals, all looking for attention to detail, durability and style.

È il dettaglio a fare la differenza per questo settore fatto di famiglie, appassionati e professionisti, che, in ogni caso, cercano cura, durevolezza ed estetica.

Ralc Italia can provide ad hoc solutions for the manipulation, the welding and the sheet processing.