Orbital cutting line, fully automated, for cutting, bending and calibrating nipples in copper, aluminium, steel and cupronickel.

High specialisation, high production

The orbital cutting line for nipples is designed to ensure the highest performance in the production of bends used in the refrigeration sector. It is available with one, two or three lanes to provide the perfect solution for all production needs. The line consists of an unwinder, straightening units, orbital cutting and bending unit. The finished pieces are unloaded on a dedicated slide. A belling unit is available as an option.

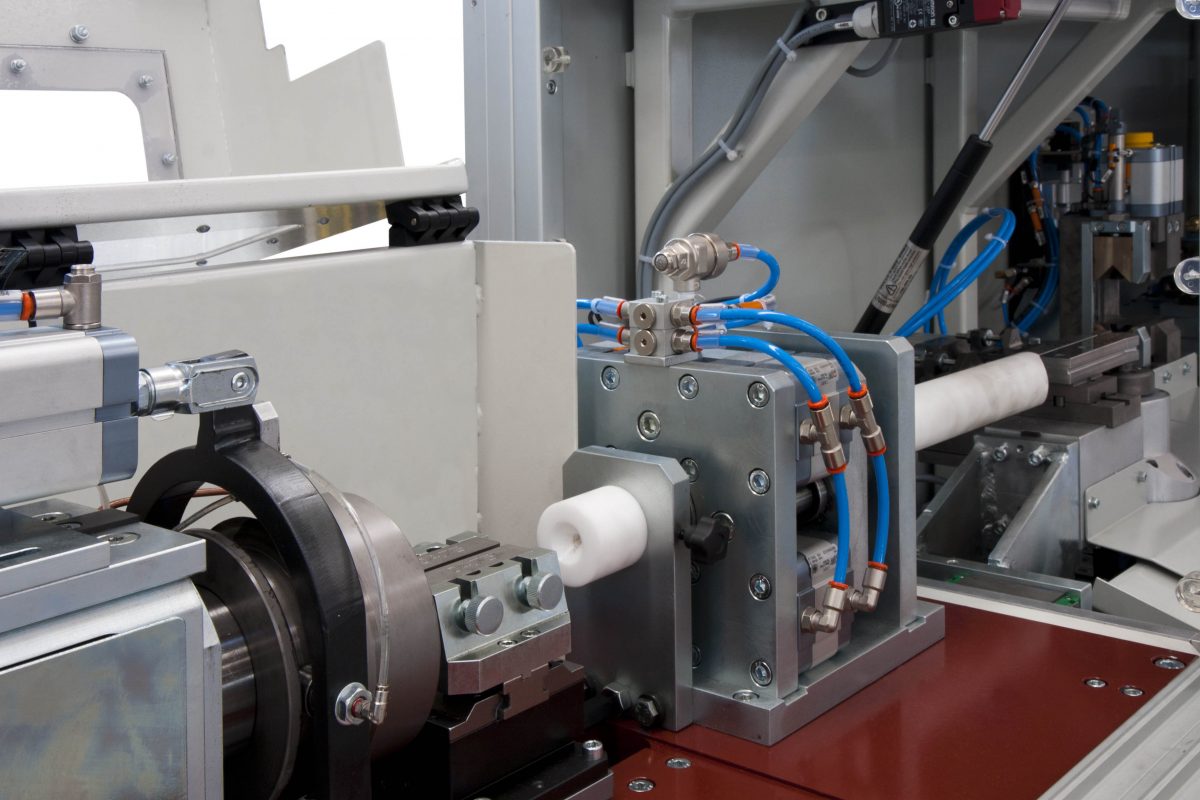

The cutting line for nipples allows pipe machining from coils. The line incorporates bending with orbital pull-apart cutting, which is carried out with minimal lubrication, adjustable from the panel and properly conveyed inside the machine to keep the work area clean. Machine changeover operations are simple and fast.

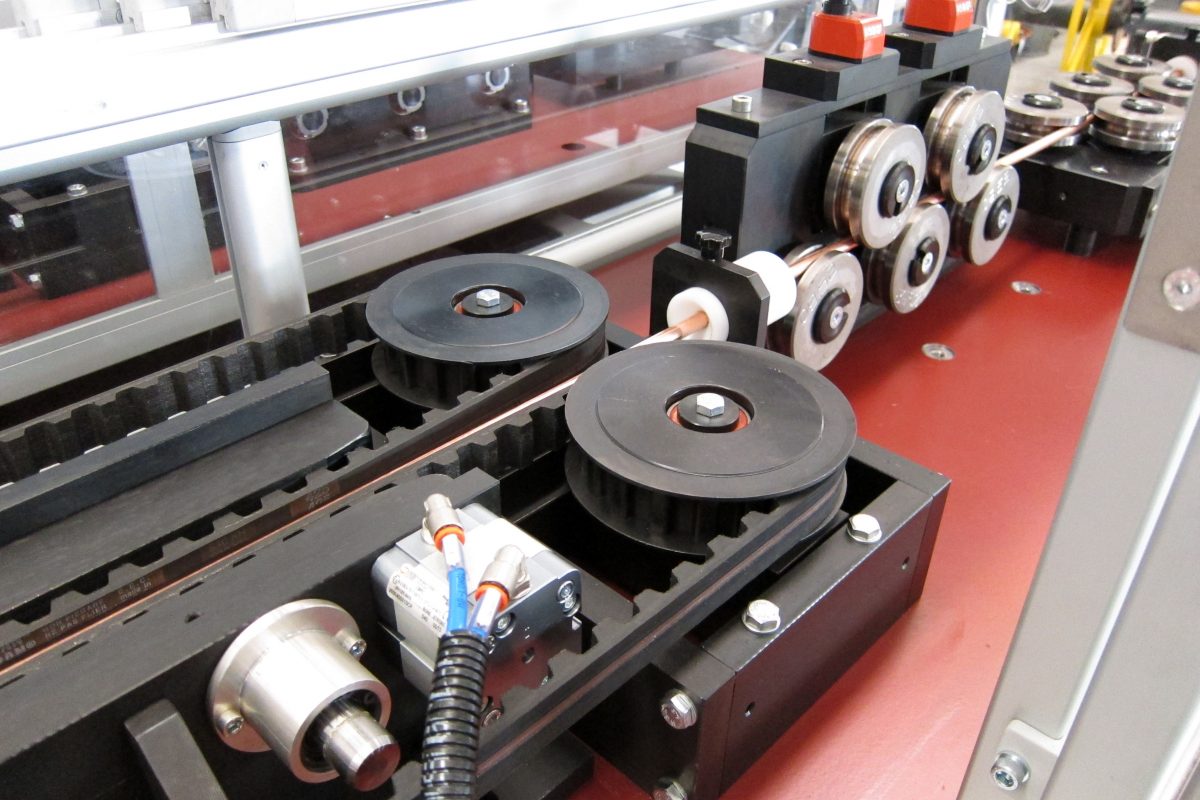

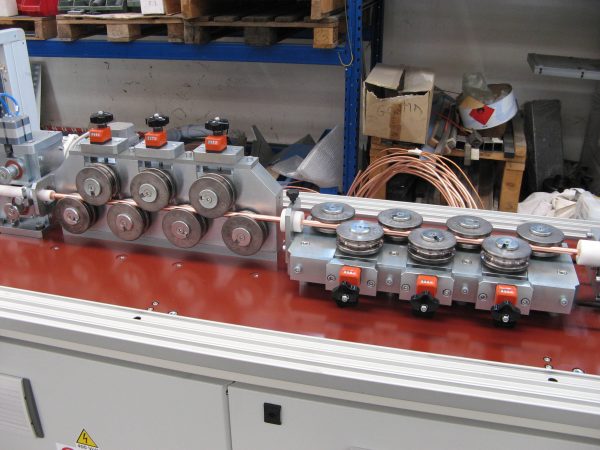

The line is equipped with two sets of five rolls, which work on the vertical plane and then on the horizontal plane to straighten the pipe coming from the coil. The pipe is fed to the cutting zone by means of a belt and brushless motor, while a pair of rolls connected to an encoder determines the cutting length. The dimensional characteristics of the nipple can be set from the panel.

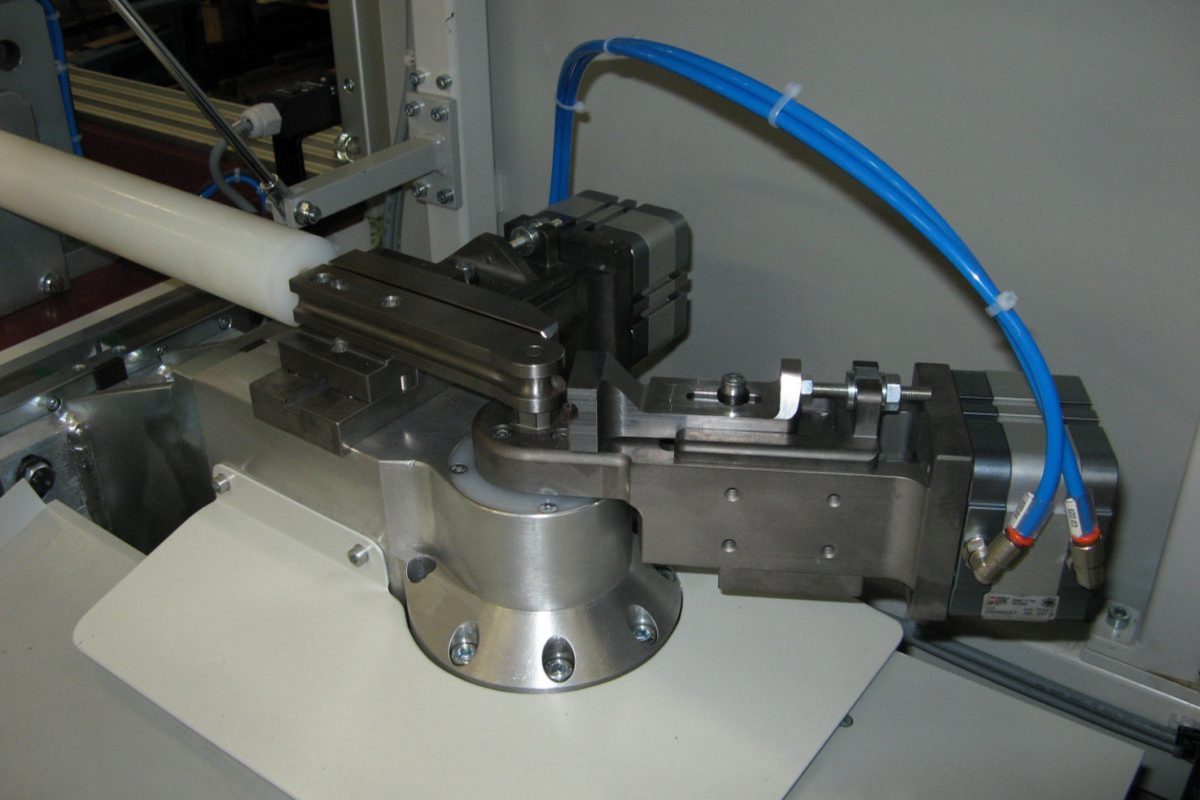

The pipe is blocked by a clamp and tensioned before cutting. The knife makes an orbital movement and the pipe is pre-cut, without separating the ends, so that it can be fed up to the bending unit, which bends the pipe, and then to the pull-apart, which separates the two pieces. The bending shape can be set from the panel with 90° and 180° nipples.

The difference is in the details, and the details make the orbital cutting line perfect for the application in which it will be used.

Thanks to the integration of additional applications, production times can be optimised, thus eliminating the cost of secondary machining and reworking of the piece on different lines.

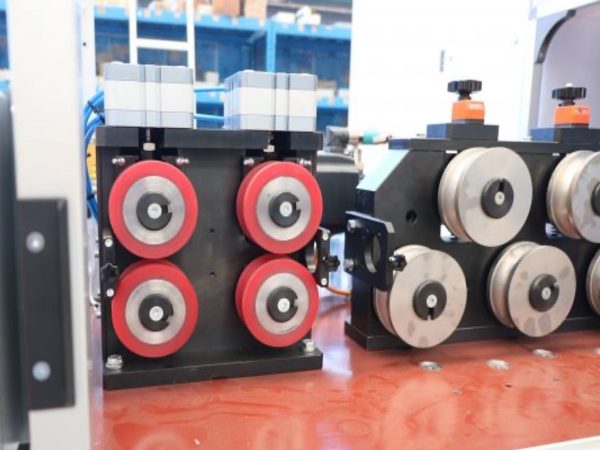

A pair of motorised twin rolls to facilitate pipe feeding into the cutting line.

Seven rolls work on the vertical and horizontal plane to straighten particularly tough materials.

Mounted on perpendicular guides, this can be activated from the panel when required for production.

The orbital cutting line finds its ideal application in the refrigeration sector.