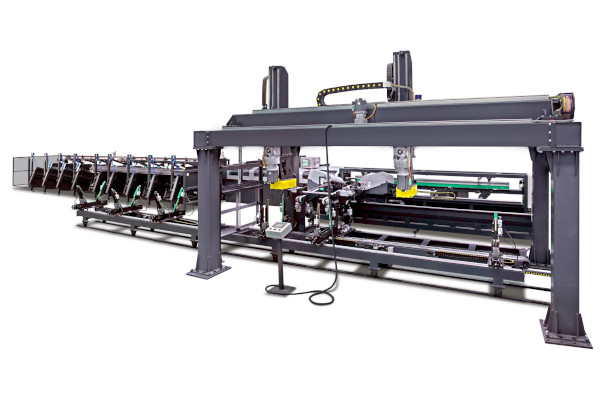

Universal automatic sawing machine for straight cutting of pipes, profiles and bars.

Agile and flexible

The “smallest” of the range, but only in price. Thanks to the structure specifically designed to combine cutting with subsequent processes, Kronos is a sawing machine well-worth considering for a broad range of applications. Its compact size is combined with a sturdy structure; the three controlled axes for feeding, cutting head positioning and unloading guarantee precision and high performance; the three specific cutting heads allow optimum cutting of steel and stainless steel, copper, brass and aluminium. With simple and fast changeover, Kronos ranges from cutting pipes with standard geometries to special profiles.

Why choose between price and quality? Kronos requires no compromise and constitutes the ideal solution for all companies looking for a fully automatic sawing machine of the highest quality at a relatively low price. Ideal for medium volumes and/or for process-based production cycles, it can also be inserted in complex production lines; regardless, extremely easy changeovers also make it perfect as a stand-alone line for simple cutting in small series; and its reliability makes it ideal for large series production.

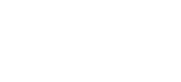

Up to 4 cutting lengths can be programmed on the one bar, or else the optimisation software can be used to manage an unlimited number of cutting lengths and optimise the waste. Saving the cutting recipes reduces the machine programming times, and the 4.0 applications make it possible to establish a direct interface between the line and the production systems. The touch screen operator panel contains numerous self-explanatory images, a valid support for the operator.

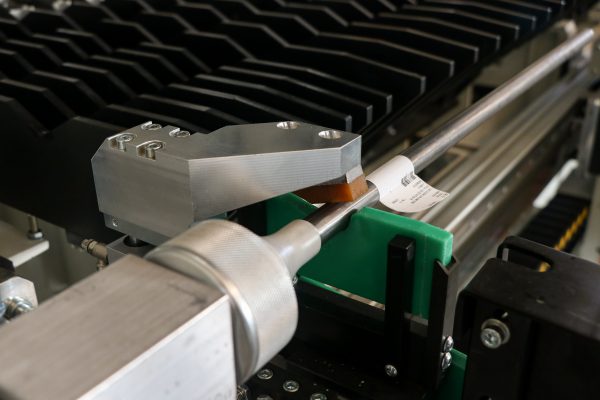

With Kronos, there are no mandatory choices: the double chain deburring system and synchronised mechatronic system make it possible to debur even the shortest pieces. The modular length unloading gripper combined with the orbital deburring tools allows deburring of extremely long pieces, with optimised feed times, also in combination with the optimisation software.

Internationally renowned companies, leaders in their various fields, have chosen Kronos to increase their level of automation. What better demonstration of the great flexibility and incredible value of this small, great sawing machine?

Thanks to the characteristics of its mechanical construction and software, Kronos perfectly adapts to smart production cycles based on piece traceability or direct interfacing with the client’s management software: tracking, marking and programming from the office are just some of the applications allowing the major players who have opted for this sawing machine to increase the smart level of their production process.

External and internal deburring for different materials, diameters and lengths. Modular systems to suit different budgets and production requirements.

A practical, fast and economical solution to remove shavings from inside the pipe. Does not remove machining oils.

Length, straightness, perpendicularity, surface control with piece mastering. Other control systems available on request.

Efficiently removes shavings and machining oils, for completely clean pipes. Available for different materials, diameters and lengths.

Drilling or moulding units can be applied downstream of the cutting operations to perform any ancillary machining necessary to complete the piece.

Allows the pipe to be rotated and position the weld as desired. Available for round and square pipes.

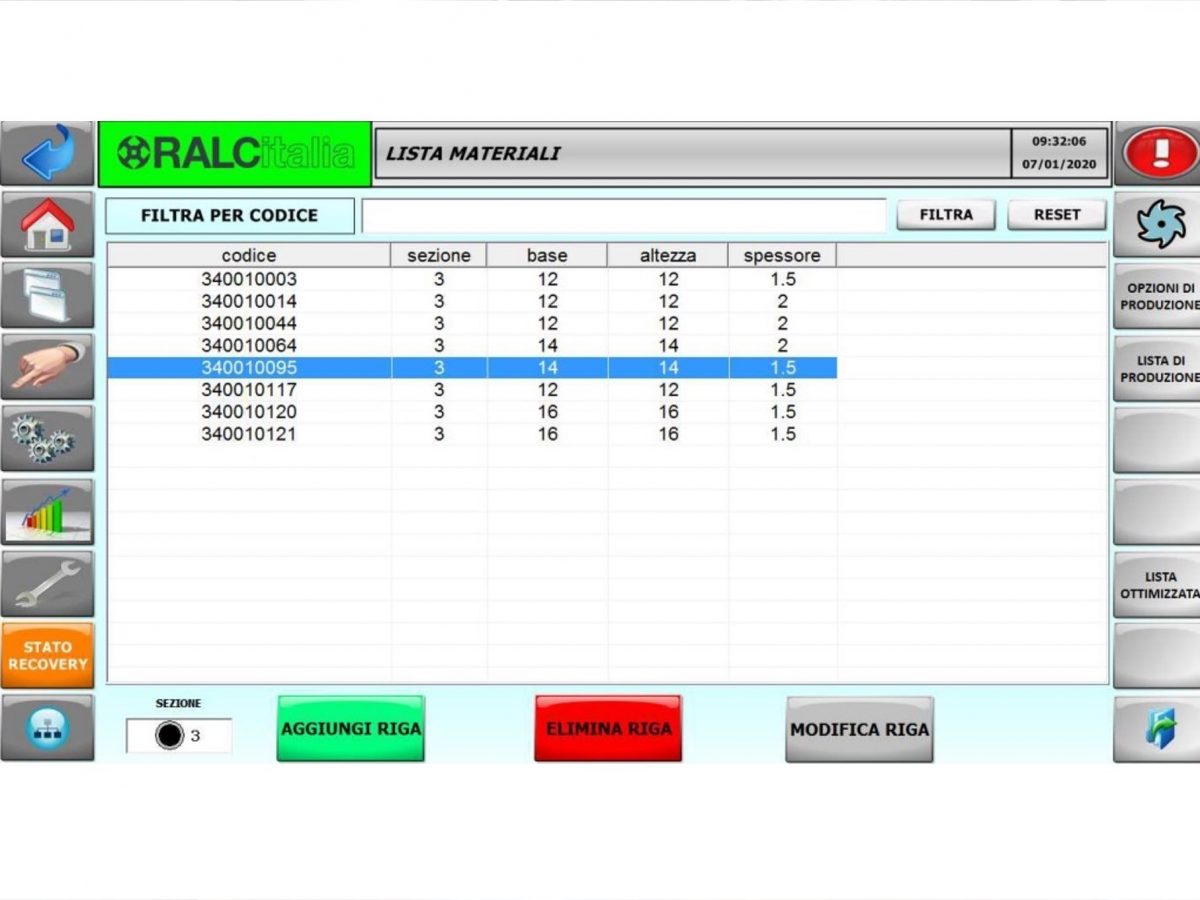

For piece traceability or to facilitate subsequent processes with coding. Engraving and percussion, laser or ink marking is available.

Various solutions are available to suit all types of budgets, production requirements and line configurations.

Kronos offers a broad range of possibilities for various types of cutting, for the broadest range of applications.