Automated line for the production of copper, aluminium and steel Serpentines. Combinable with manual marking and bending units.

Tireless and systematic

The meticulous attention to detail, the quality of the materials and components, and highly evolved software come together to create a reliable, tireless and systematic line selected by the best professionals in the refrigeration sector. The base line guarantees all the functions necessary to produce high-quality serpentines, and can be further enriched with options that increase its productivity, or which are needed to perform additional machining.

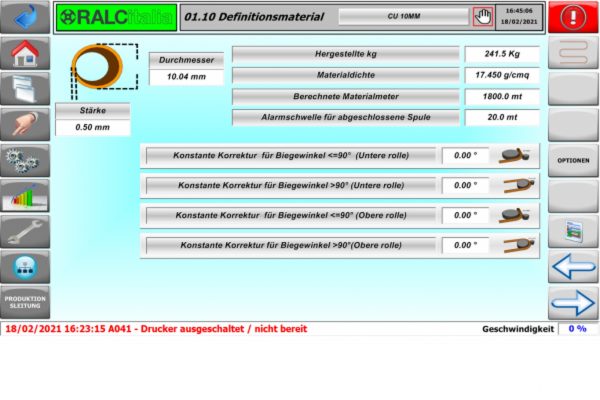

Allows great flexibility in the shape of Serpentines: thanks to the simple and fast changeover system, and rapid and intuitive programming, it is possible to adjust the radii, lengths and rows in minimal time. Whether for small products or long serpentines with a high number of rows, precise straight sections and bends of the highest quality are guaranteed, and therefore an aesthetically pleasing serpentine and high repeatability of machining.

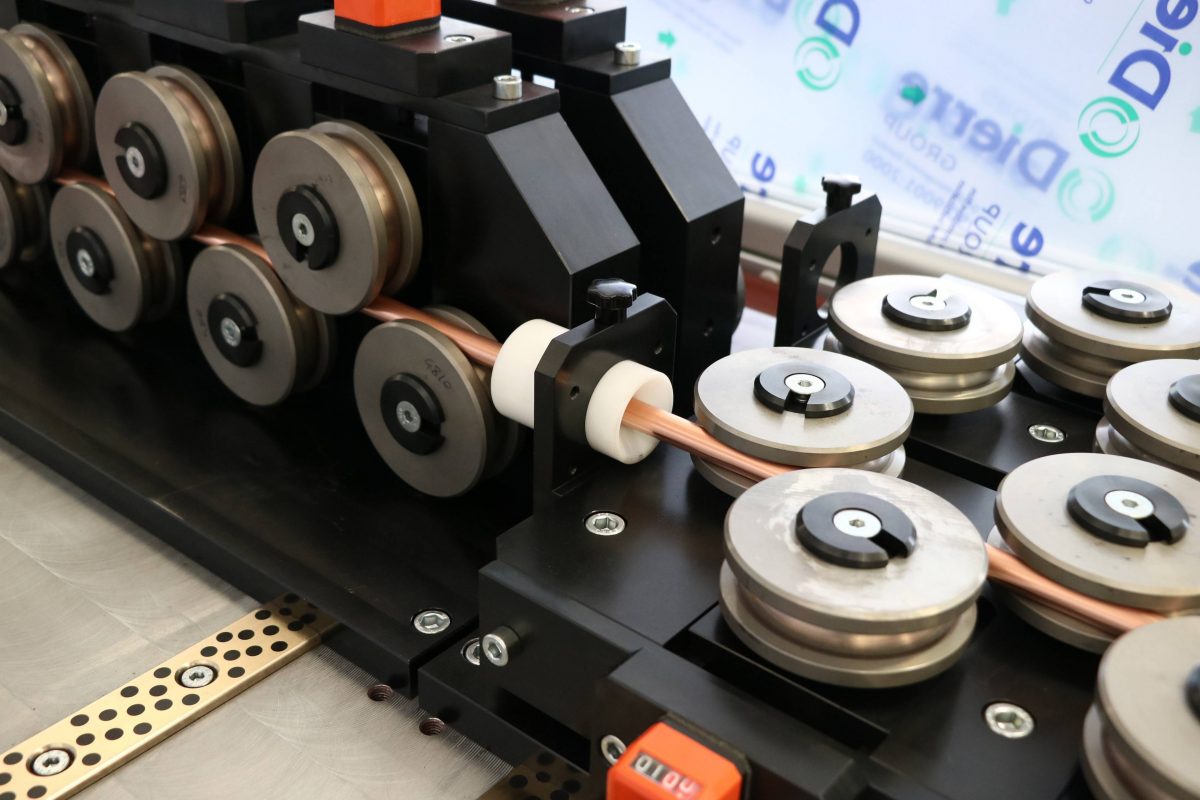

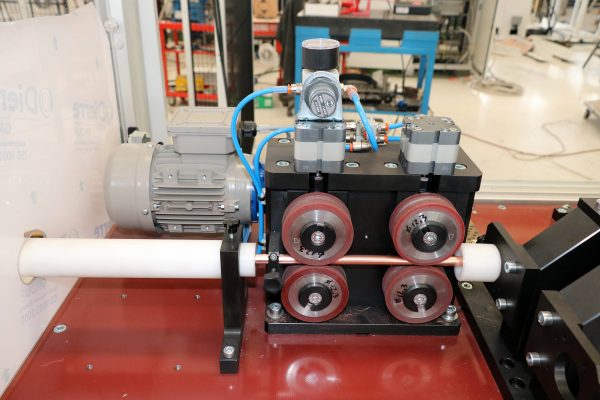

Two sets of seven rolls, one on the vertical plane and one on the horizontal plane, straighten the pipe coming from the coil. The pipe is fed towards the cutting zone by belts driven by a brushless motor controlled by a dedicated drive, while a pair of rolls connected to an encoder determines the length of cutting, which occurs by way of an orbital pre-incision. The two ends are separated by the bending rolls.

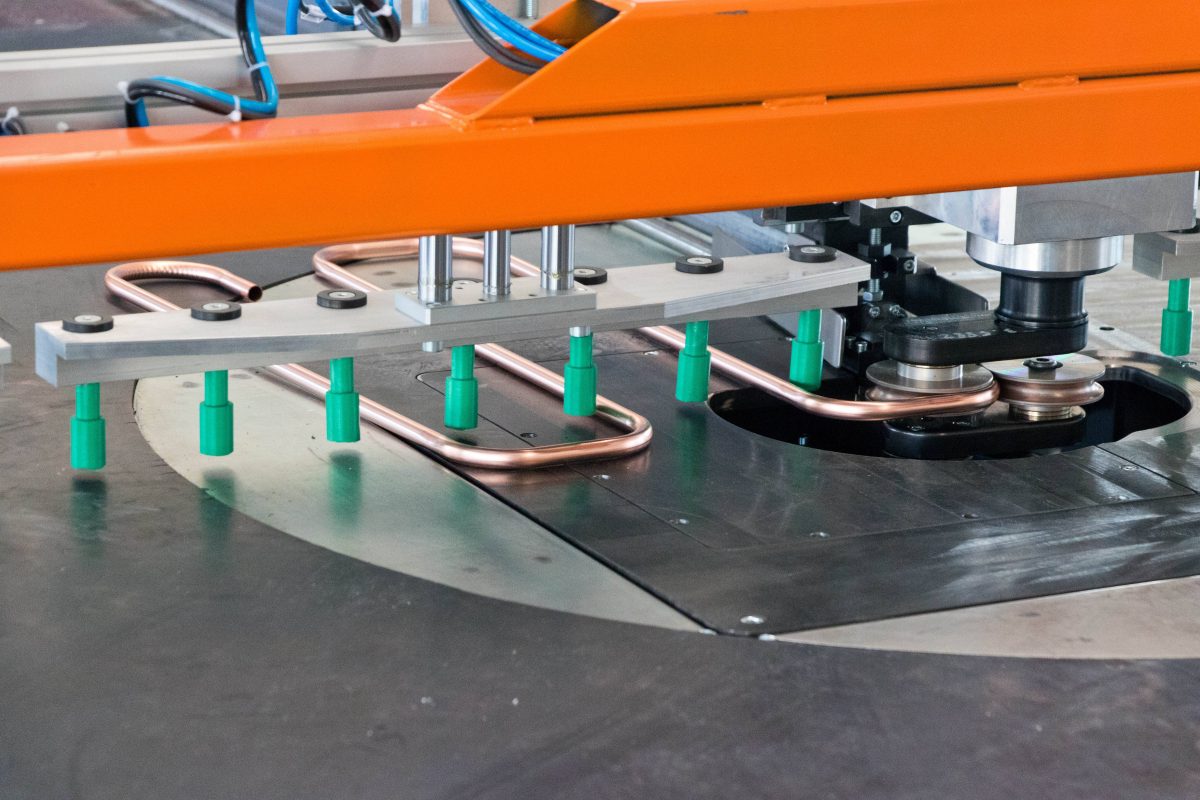

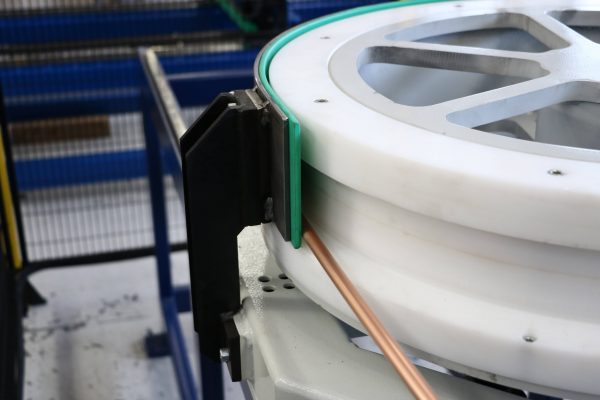

The roll bending unit allows bends to the right and left. It is positioned at the centre of a support table, which, through synchronised rotation with the bending unit, supports the coil, thus avoiding its deformation. An arm fitted with vertical inserts guides the coil during the feeding stage and blocks it during rotation, thus preserving its geometry and linearity. At the end of machining, the arm unloads the coil.

The standard set-up can be integrated with practical and functional solutions from among a rich selection of options. This makes for even easier material loading and machine tooling on the part of the operator, while also improving production flexibility and organisation. The same machine sizes can be modulated to suit the size of the coil to avoid pointless wastes of space.

Thanks to this practical gripper, lifting the coil is no longer that hard. A precious ally for every operator, at a reasonable cost.

Efficiently avoids any excessive unwinding of the coil, modulating the pipe tension and performing a braking function.

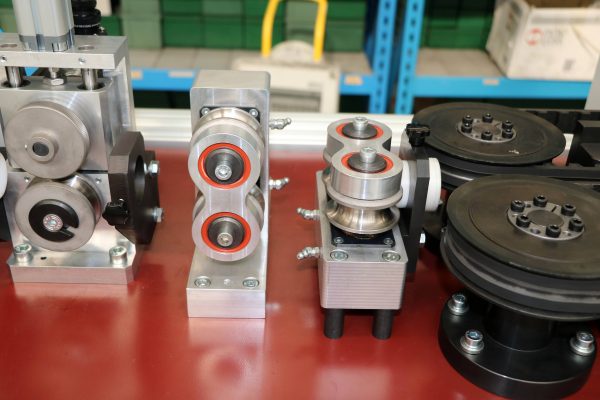

Two pairs of motorised rolls facilitate the operator’s task of inserting the pipe in the subsequent straightening units.

Mounted on guides, it significantly reduces tooling times. Particularly suited for companies that work with two materials.

These work on a vertical and horizontal plane and guarantee the roundness of the pipe along its entire length.

A small slide positioned after each cutting unit facilitates the unloading of straight pieces. Two functions in one machine.

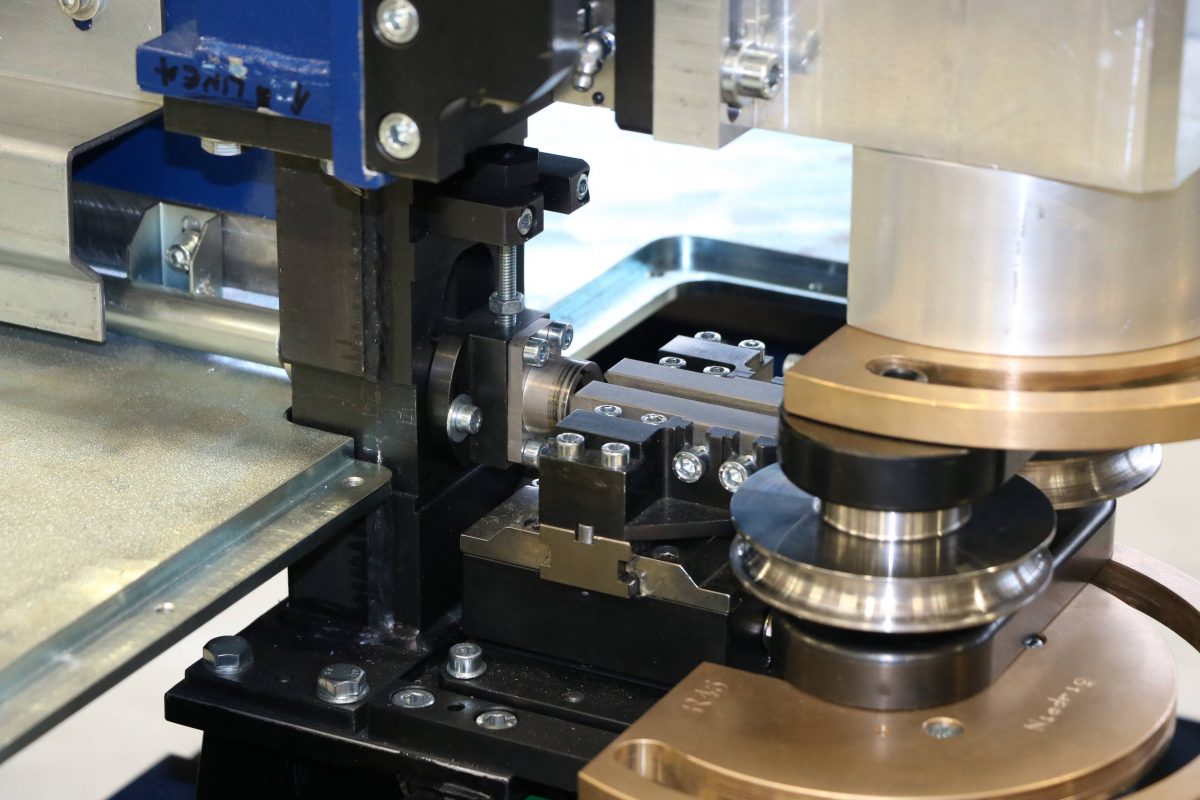

To insert bushings on the end of the pipe and calibrate it, then bend the pipe on the same plane as the coil or a different plane in the next station.

Essential in facilitating and speeding up production, allows machine programming directly from the office, based on the order received. All it takes is a click.

The serpentine bender, when properly equipped is an extremely versatile and flexible line, making it possible to obtain the perfect product in all types of production.