“The world is moving so fast these days that the man who says it can’t be done is generally interrupted by someone doing it.” Elbert Hubbard

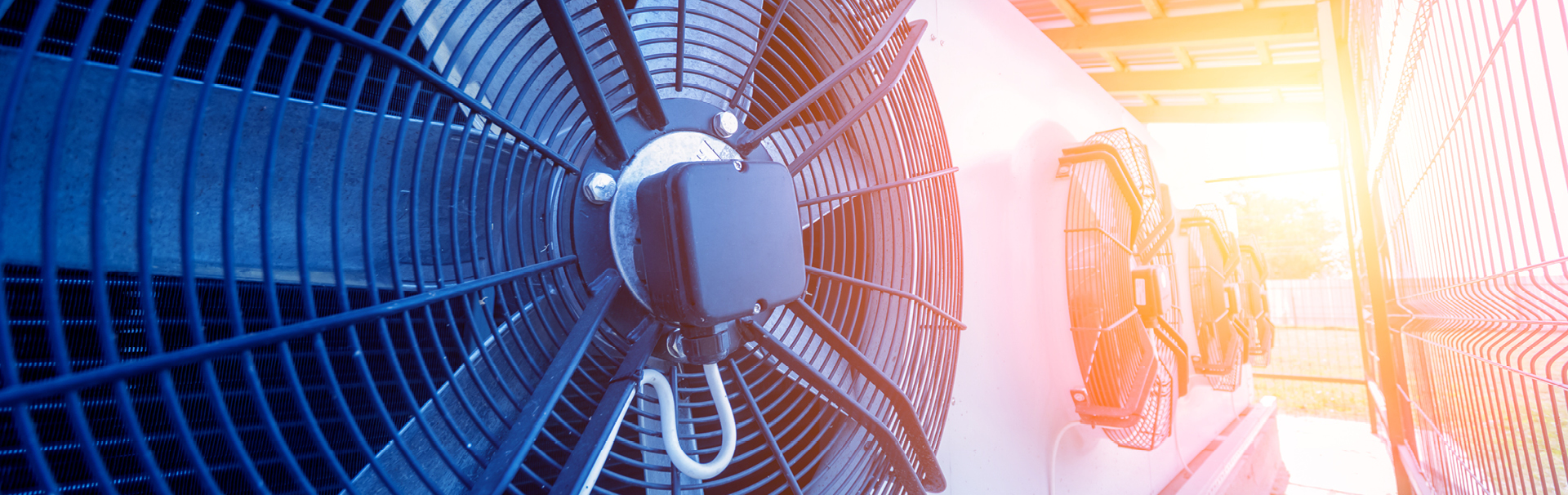

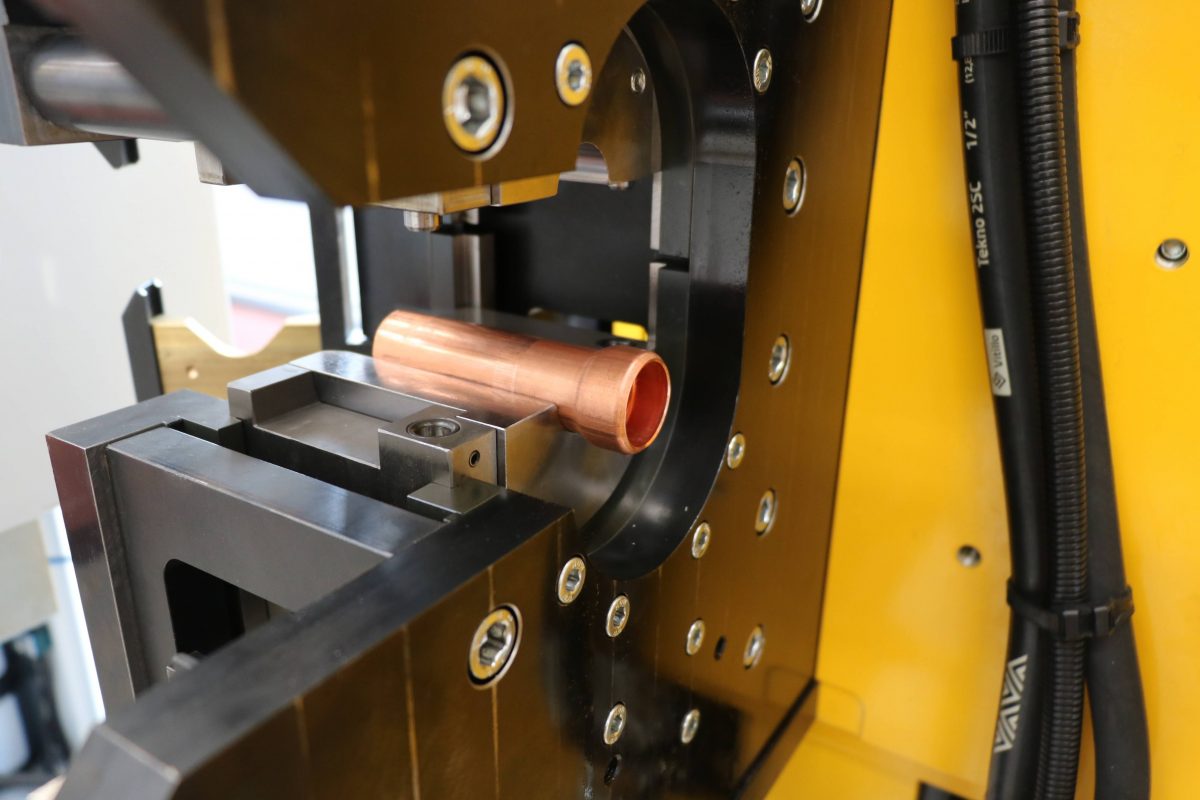

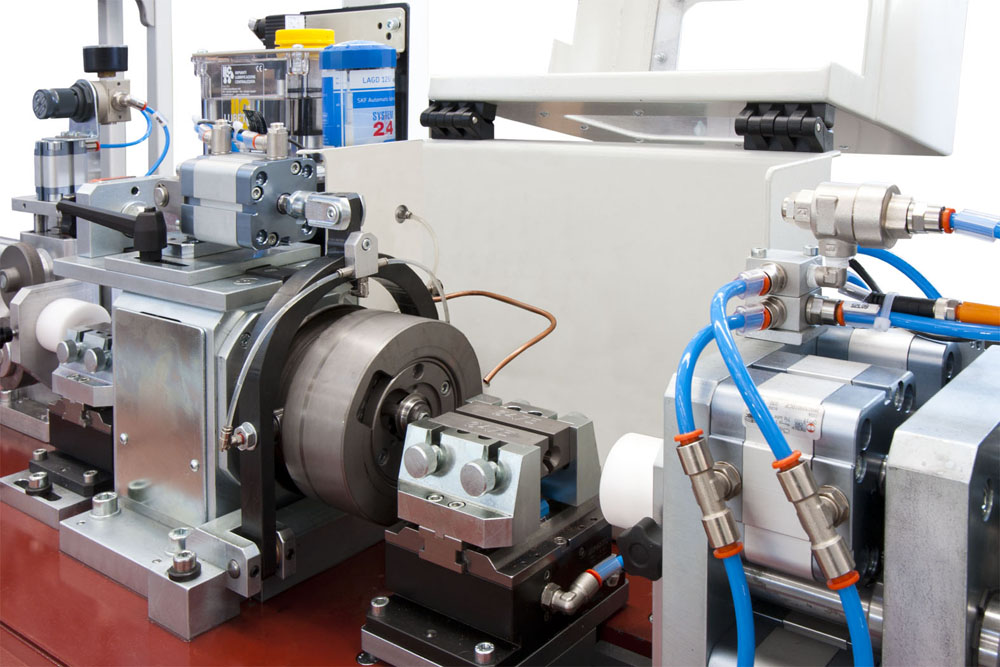

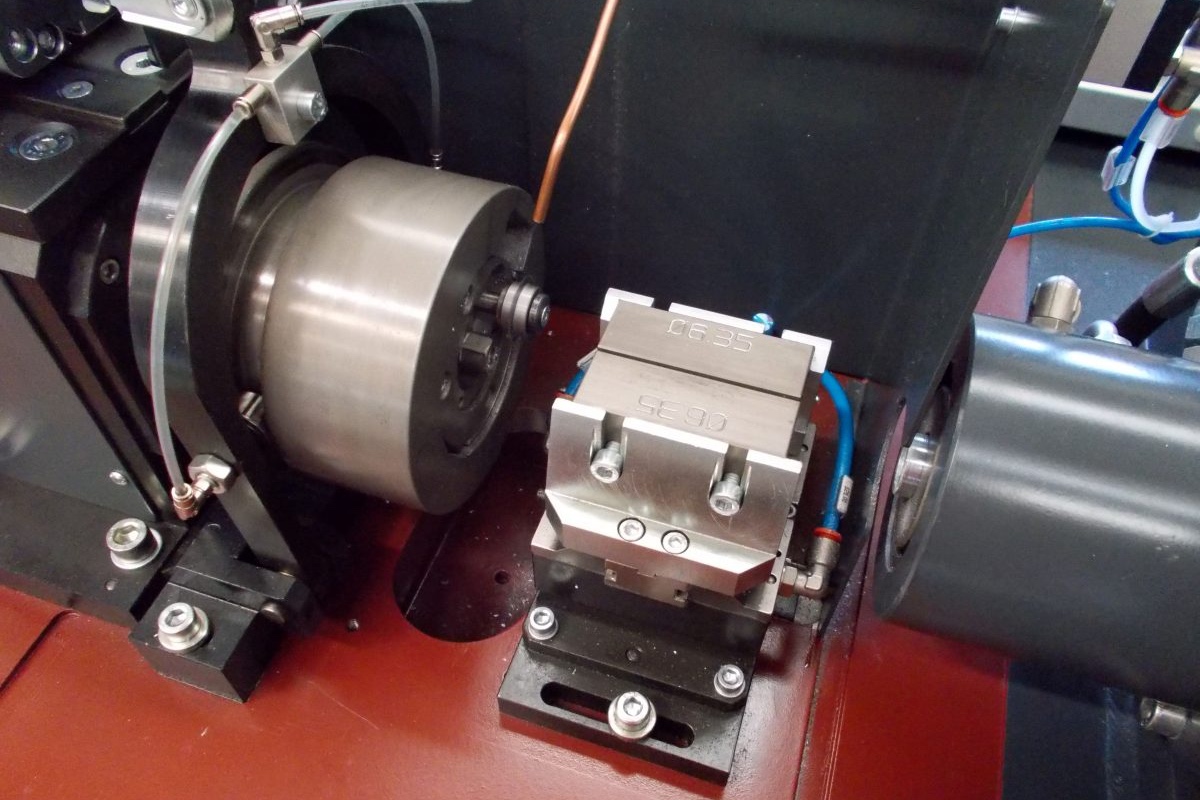

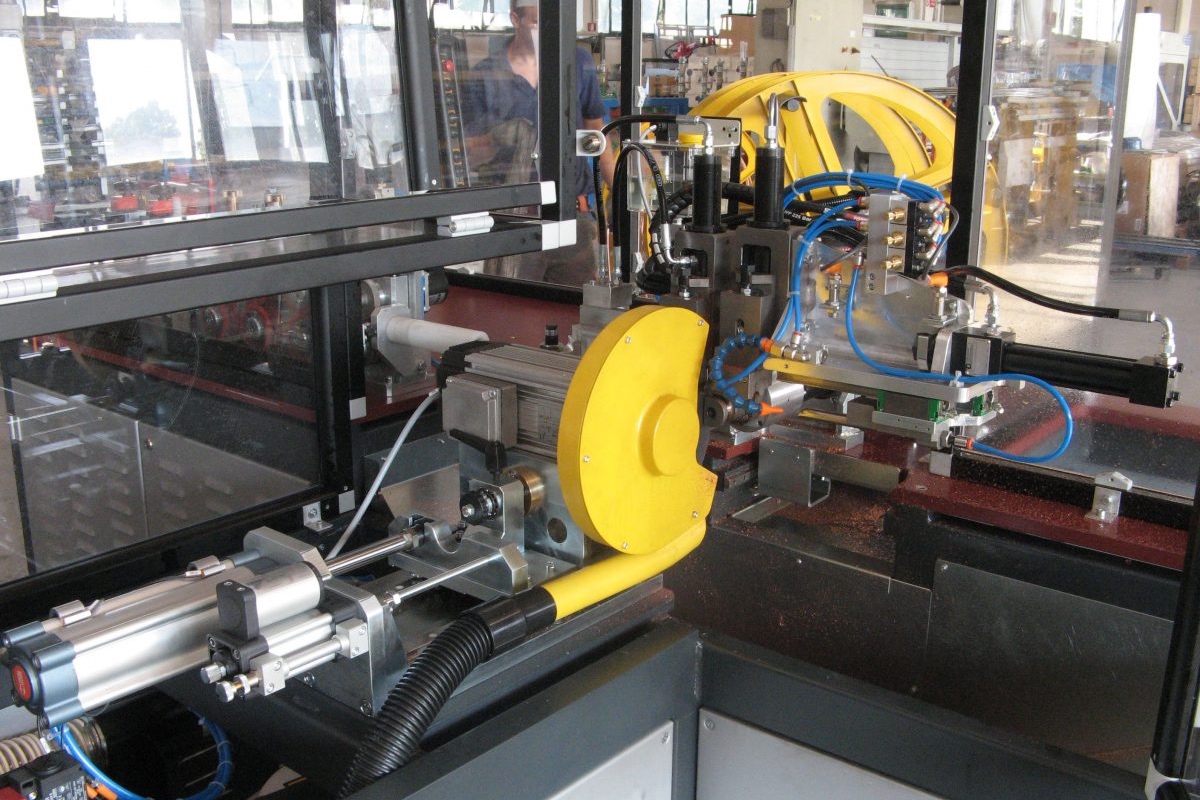

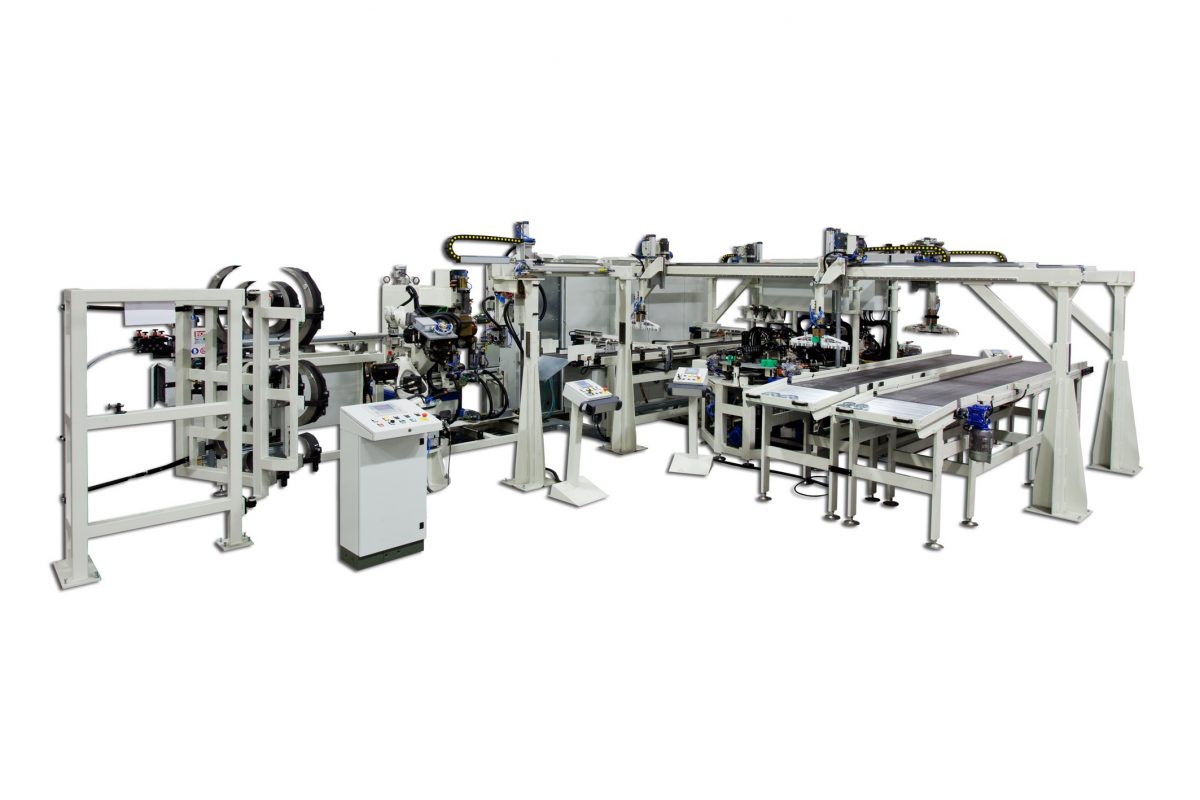

30 years ago Ralc Italia was founded to satisfy the needs of the refrigeration sector, designing lines to respond to cutting, end forming and sheet metal machining needs, today stable fixtures of the Ralc range, a guarantee of reliability, durability and quality for the most important clients throughout the world who work in this fascinating sector.

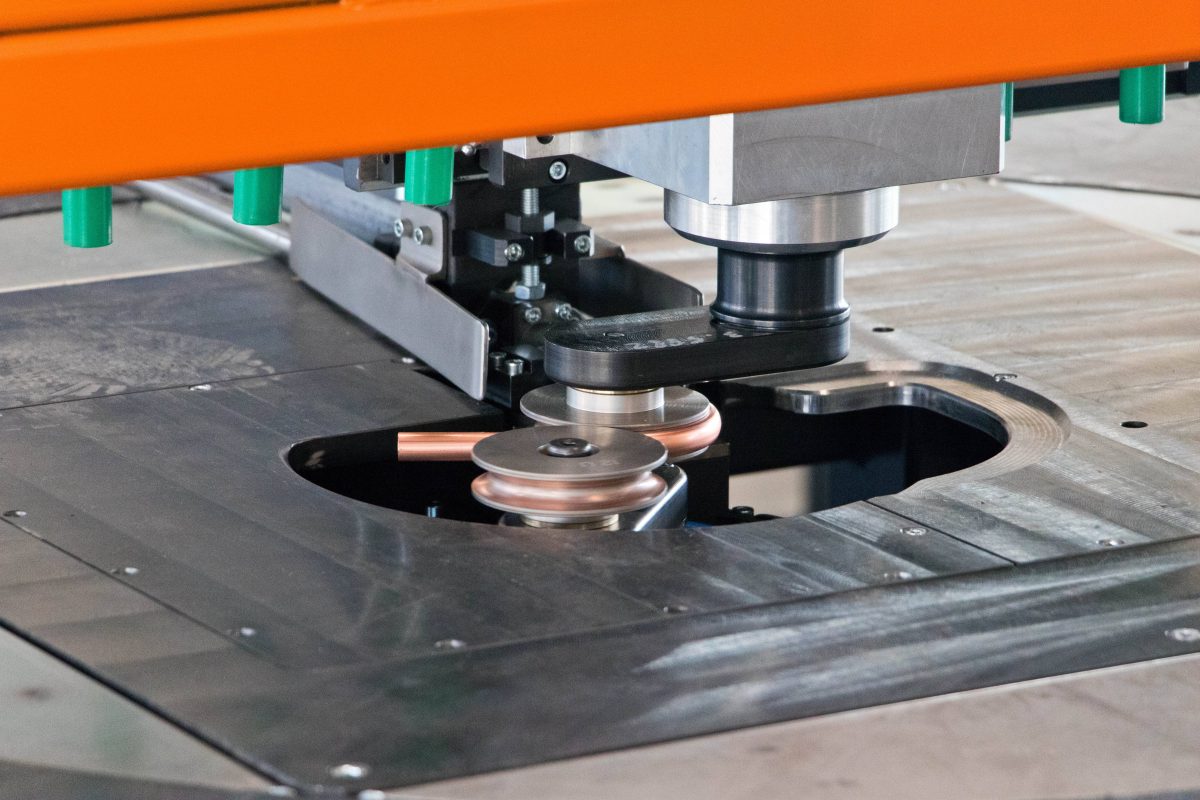

Whether for copper, aluminium or steel, Ralc Italia offers guaranteed solutions for the heating and cooling sector.

Ralc Italia can provide ad hoc solutions for the manipulation, the welding and the sheet processing.