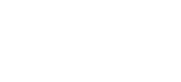

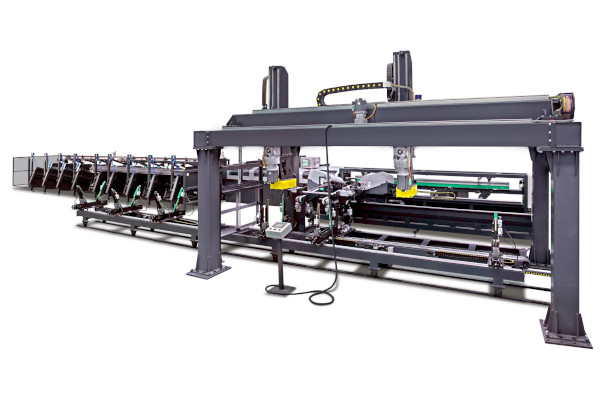

Universal automatic sawing machine for straight and angular cutting of pipes, profiles and bars.

Powerful and versatile

Extremely flexible and versatile, Nuova Lybra is the ideal sawing machine to ensure the highest level of automation in various types of production. It allows straight and angular cutting of a broad range of pipe sections and materials of varying thickness, and guarantees high performance thanks to the capacity for single, double and triple cutting. Its sturdy structure, clamping and axis management allows high-level precision, and the changeover speed also makes it ideal for small series.

The cutting head with completely automatic positioning is available for steel, stainless steel, aluminium, copper or brass. The modular structure allows the development of a cutting line perfectly customised to suit individual needs. Automatic loading is guaranteed for round, square, rectangular or special pipes and bars, for any length and production volume with rapid changeover. Nuova Lybra can also be combined with different types of automatic unloaders, for variable lengths.

The touch screen operator panel enriched with self-explanatory images assists and guides the operator in managing the broad range of functions offered by the software. The Siemens PC allows the saving, export, import and recall of complete cutting programs for efficient and fast organisation of production, even by remote. Small and large production batches can be set up with just a few simple touches.

The positioning of all clamps through the operator panel allows fast and efficient changeovers for continuous production without any downtime. The machine automatically separates the good pieces from the scrap, as well as the different cutting lengths, thus reducing operator input to a minimum. The integrated optimisation software minimises waste in all working conditions.

The production process can be completed and enriched by additional machining and special applications. The automation of additional production processes reduces labour costs and allows unattended production, thus increasing the value of the cut piece.

The machine comes with integrated reporting for production monitoring and predictive maintenance, which can be customised to suit the needs of every client according to the principles of industry 4.0.

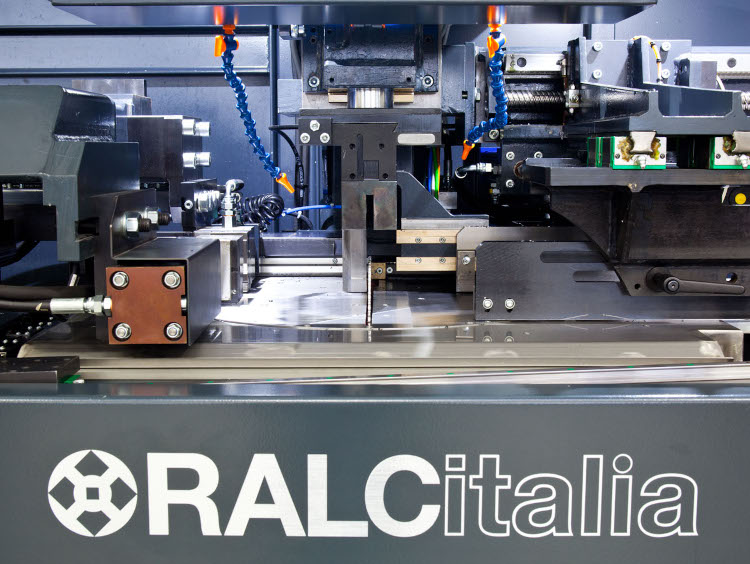

External and internal deburring for different materials, diameters and lengths. Modular systems to suit different budgets and production requirements.

A practical, fast and economical solution to remove shavings from inside the pipe. Does not remove machining oils.

Length, straightness, perpendicularity, surface control with piece mastering. Other control systems available on request.

Efficiently removes shavings and machining oils, for completely clean pipes. Available for different materials, diameters and lengths.

Drilling or moulding units can be applied downstream of the cutting operations to perform any ancillary machining necessary to complete the piece.

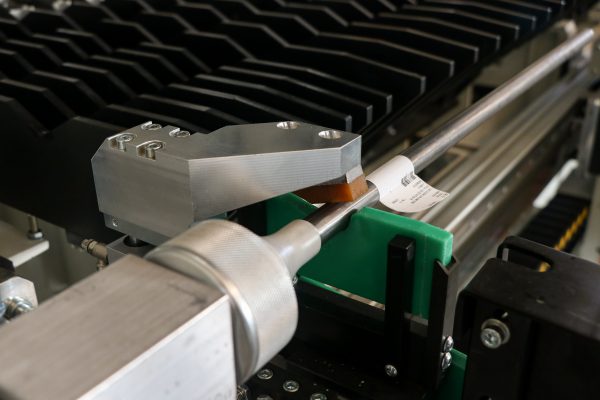

Allows the pipe to be rotated and position the weld as desired. Available for round and square pipes.

Various solutions are available to suit all types of budgets, production requirements and line configurations.

Thanks to its versatility, Nuova Lybra can be used in the broadest range of fields: furniture and furnishings, construction, collectibles, medical, automotive.