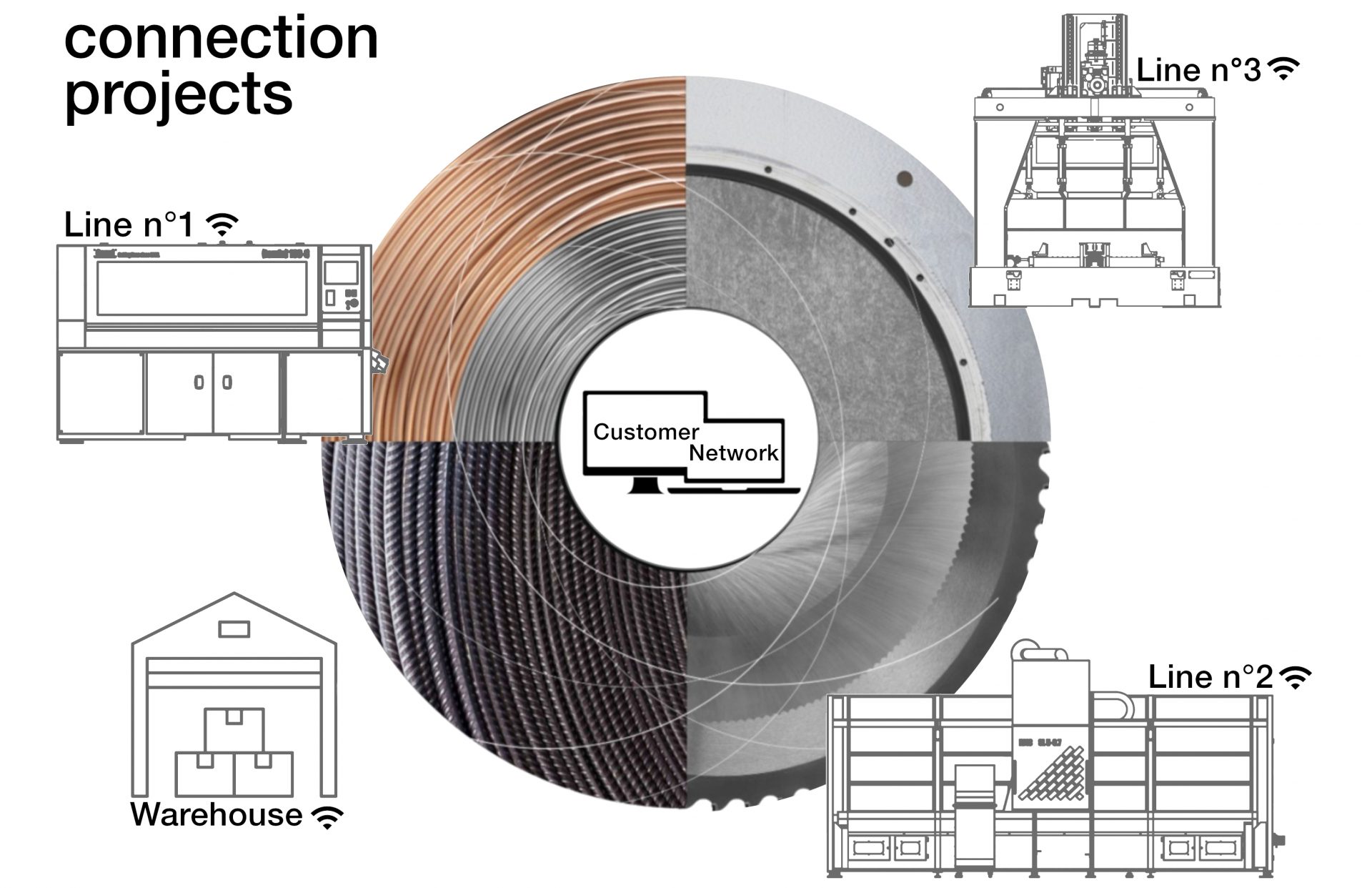

A pioneer in the development of industry 4.0 applications, Ralc Italia boasts SMART FACTORY projects with worldwide industrial leaders in various production sectors.

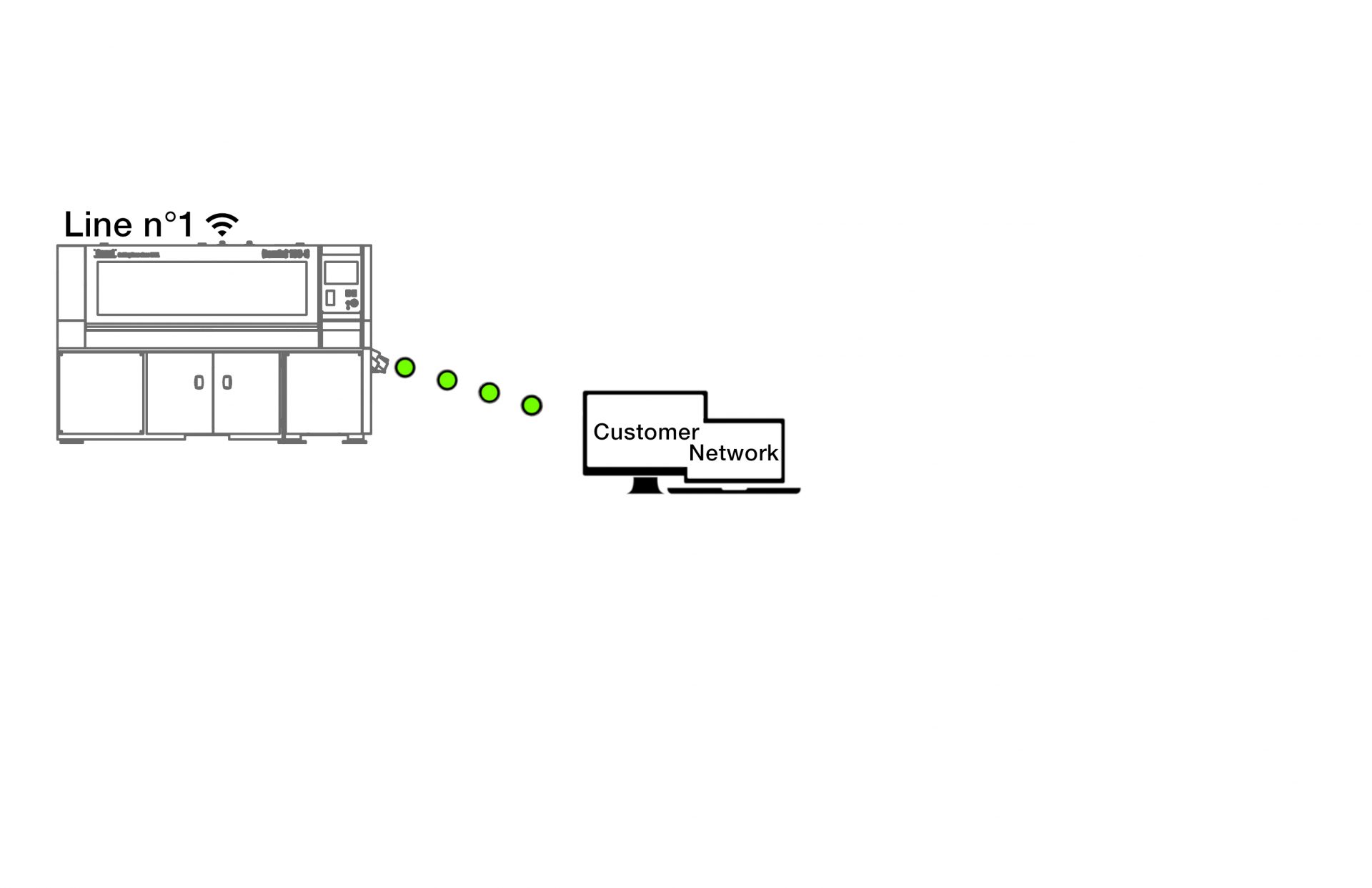

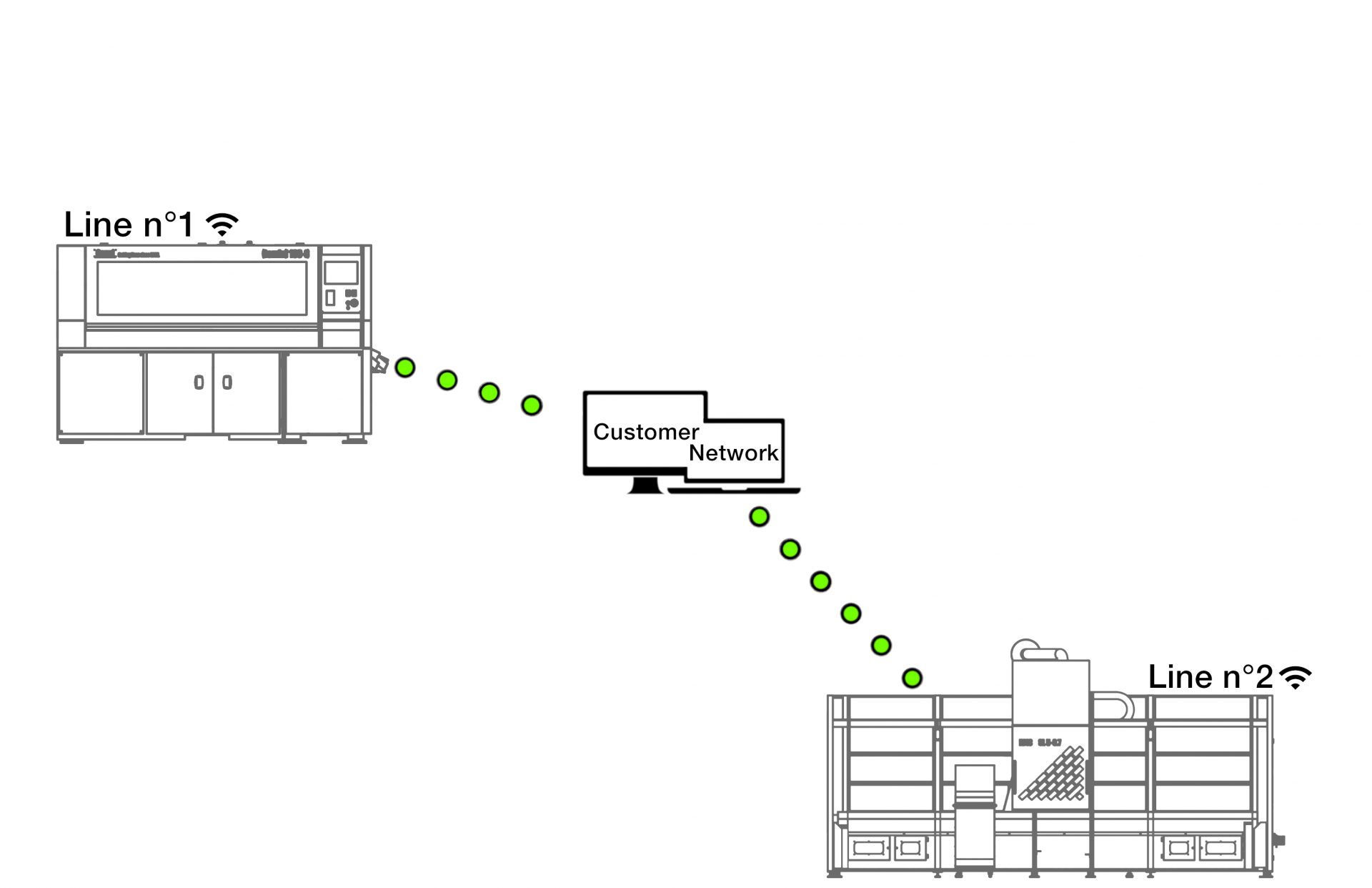

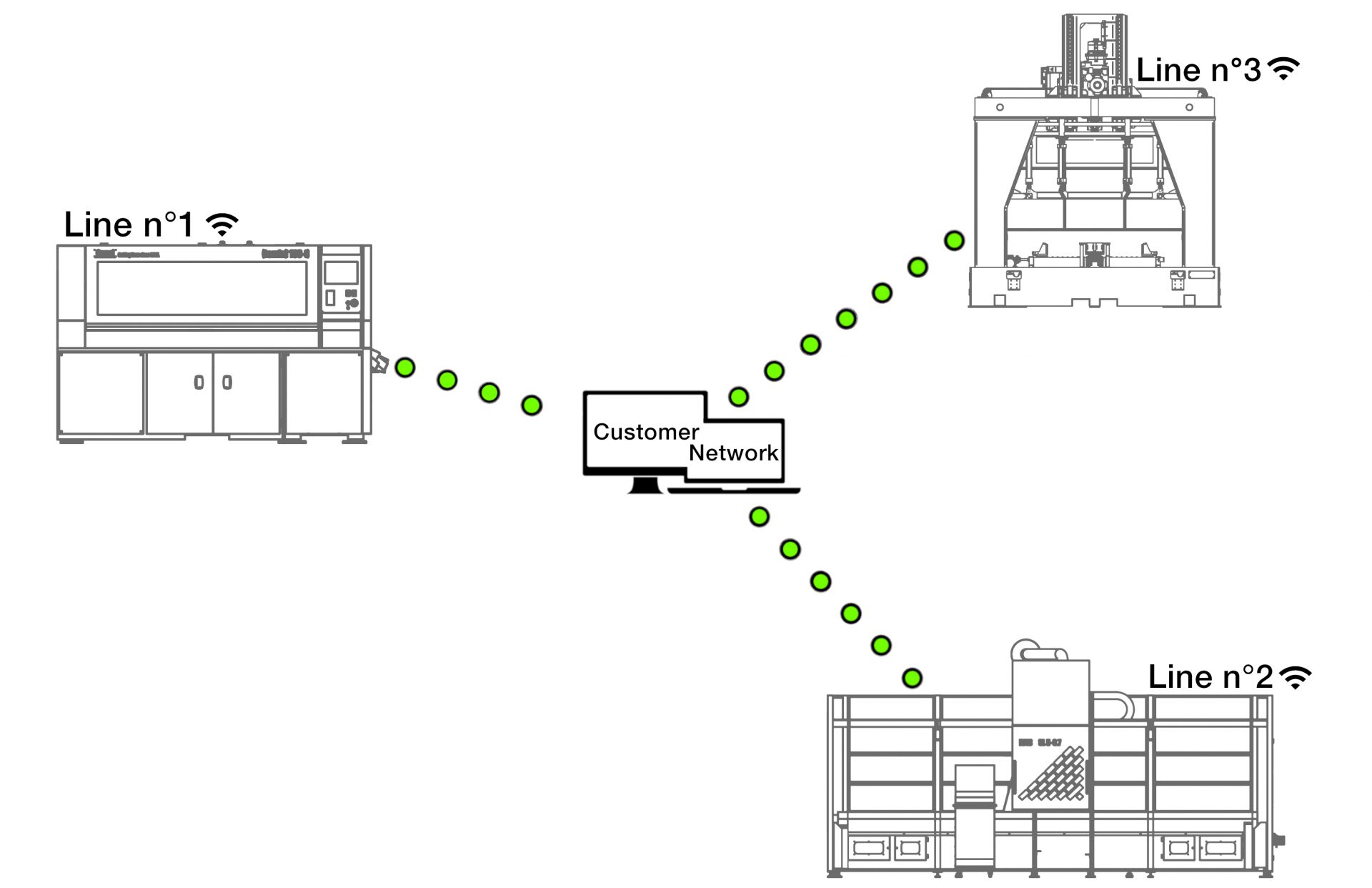

For more than 15 years, Ralc Italia systems have been enabled for the digital exchange of information to allow monitoring of production processes.

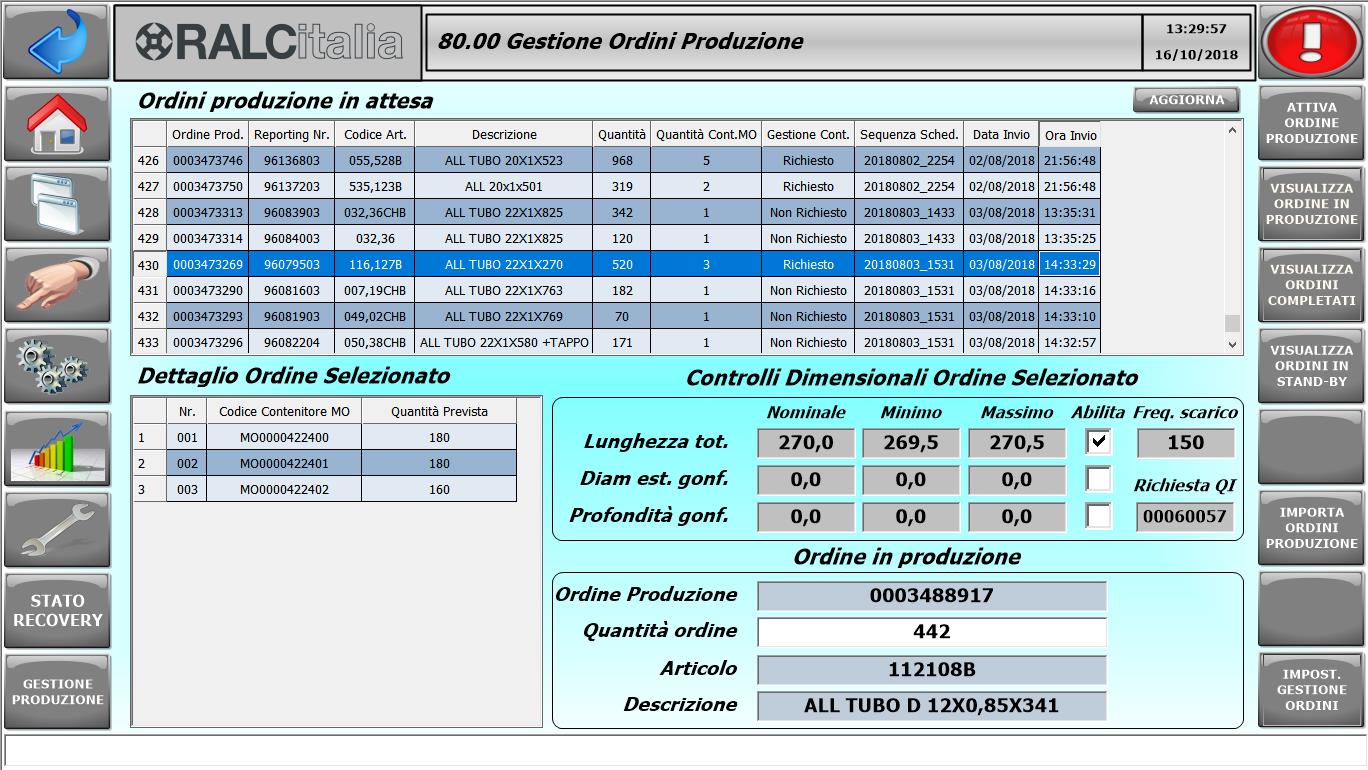

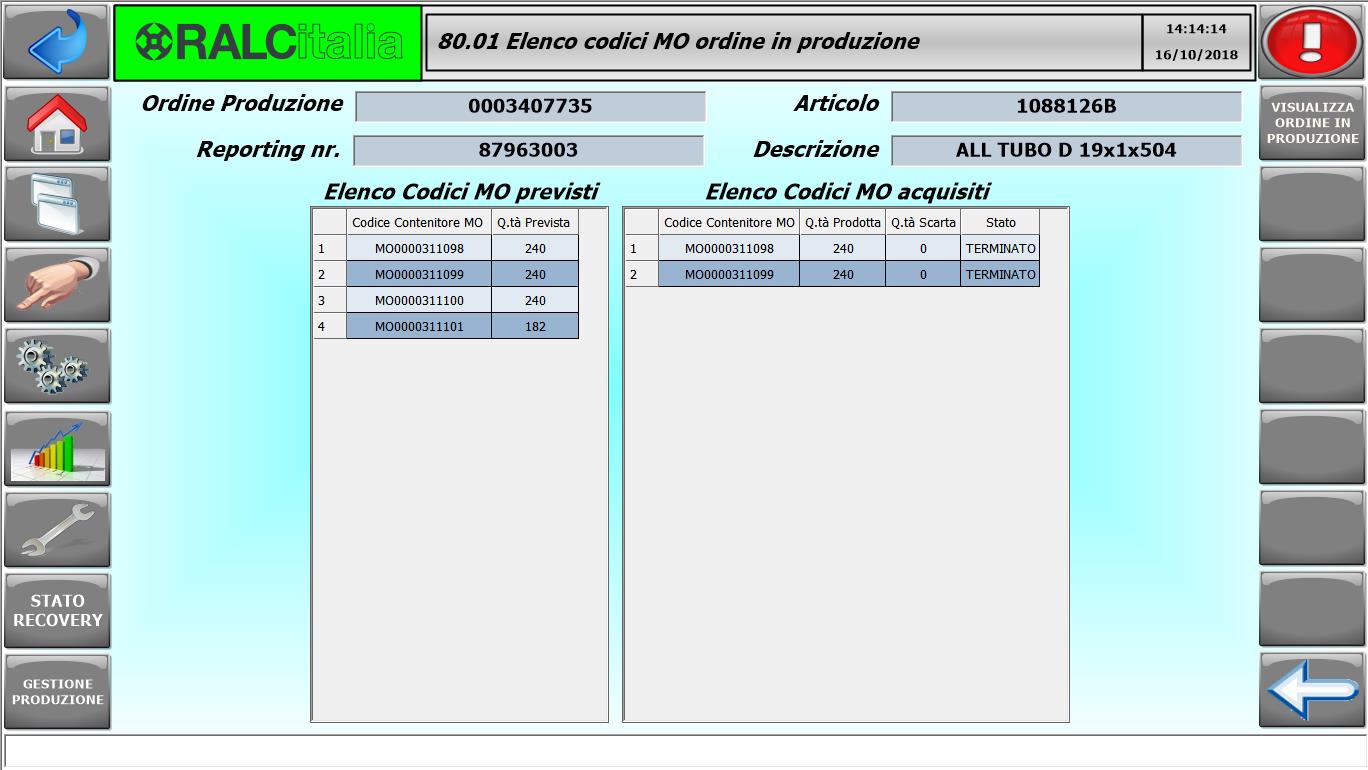

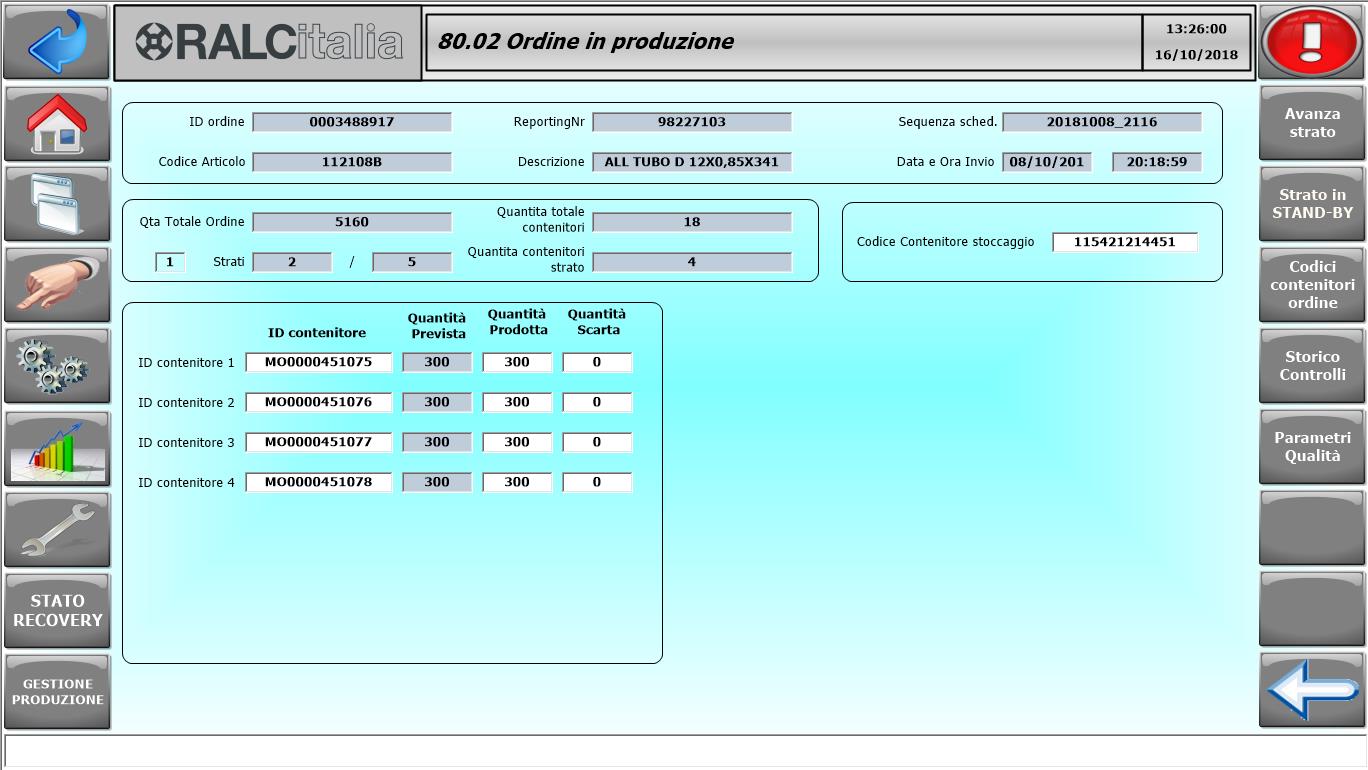

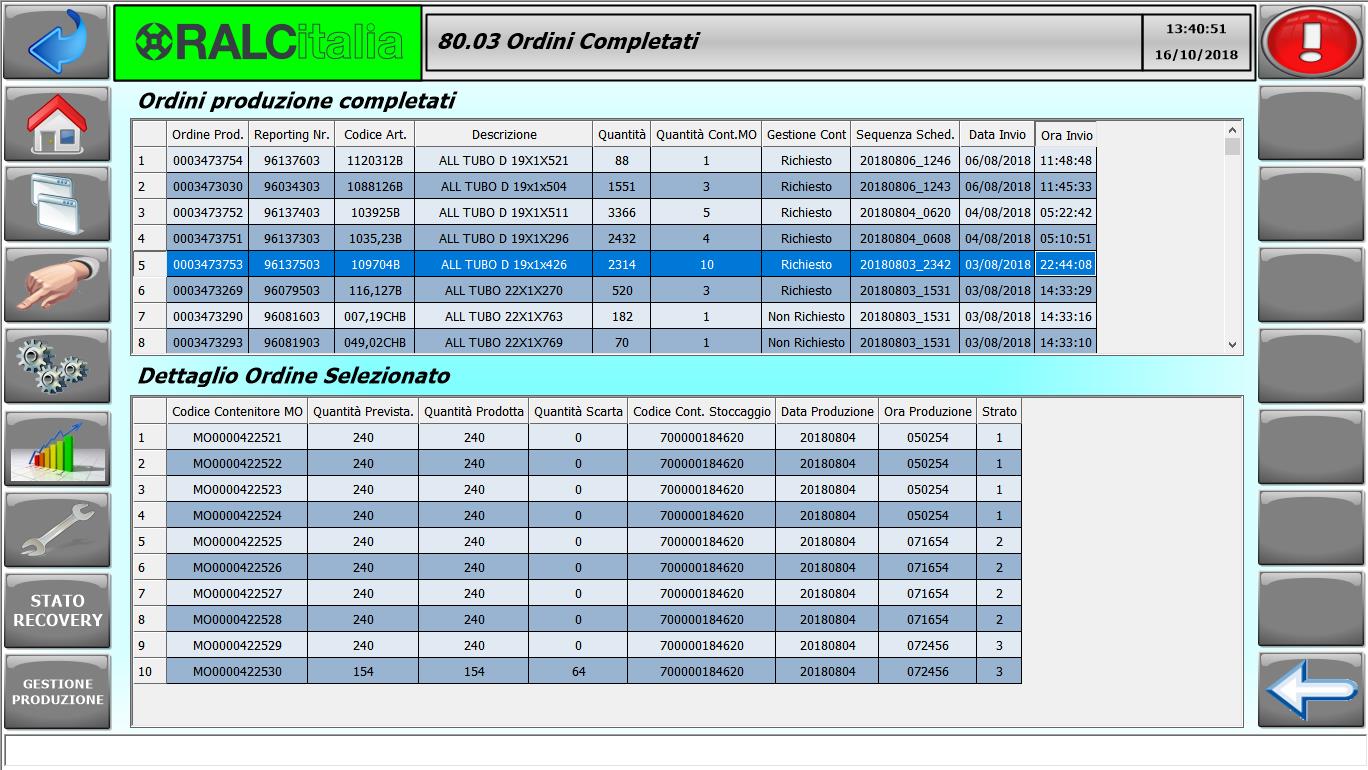

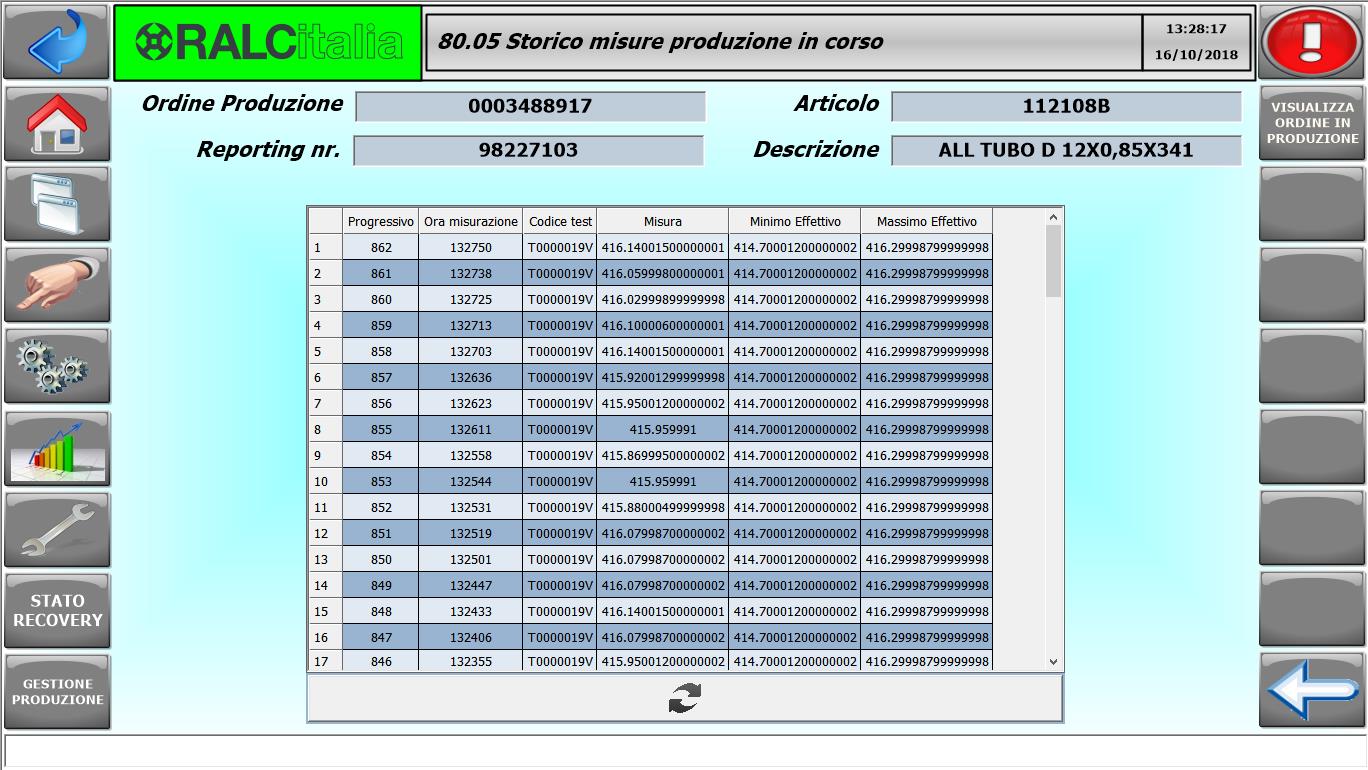

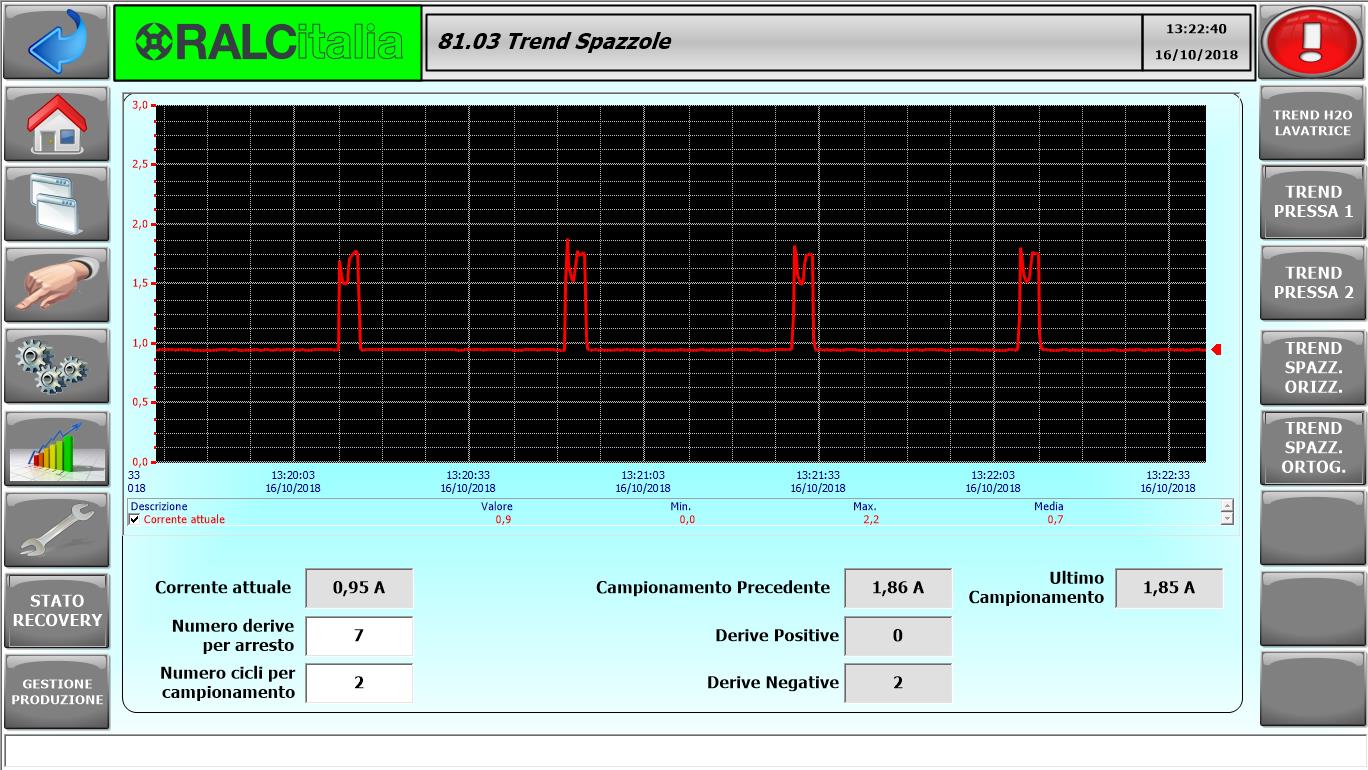

You can monitor the progress of production in real time.

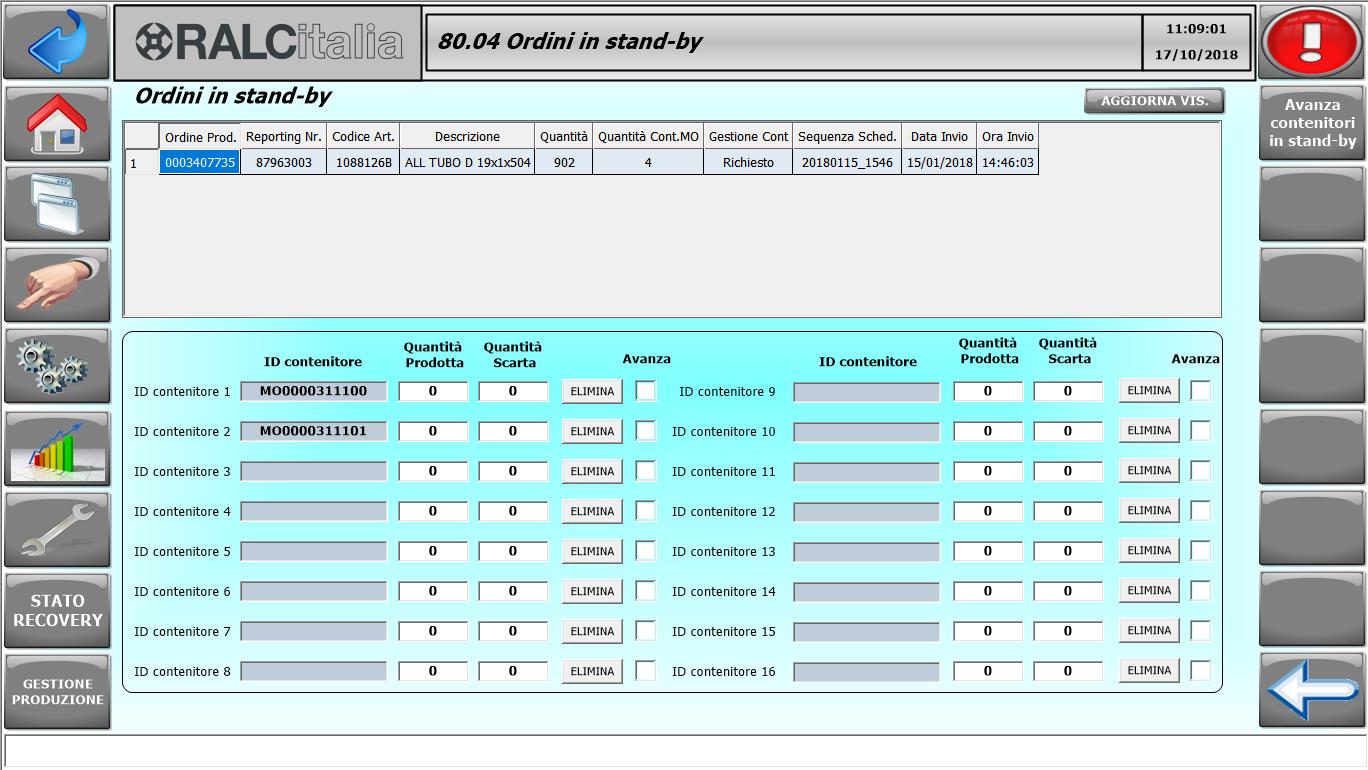

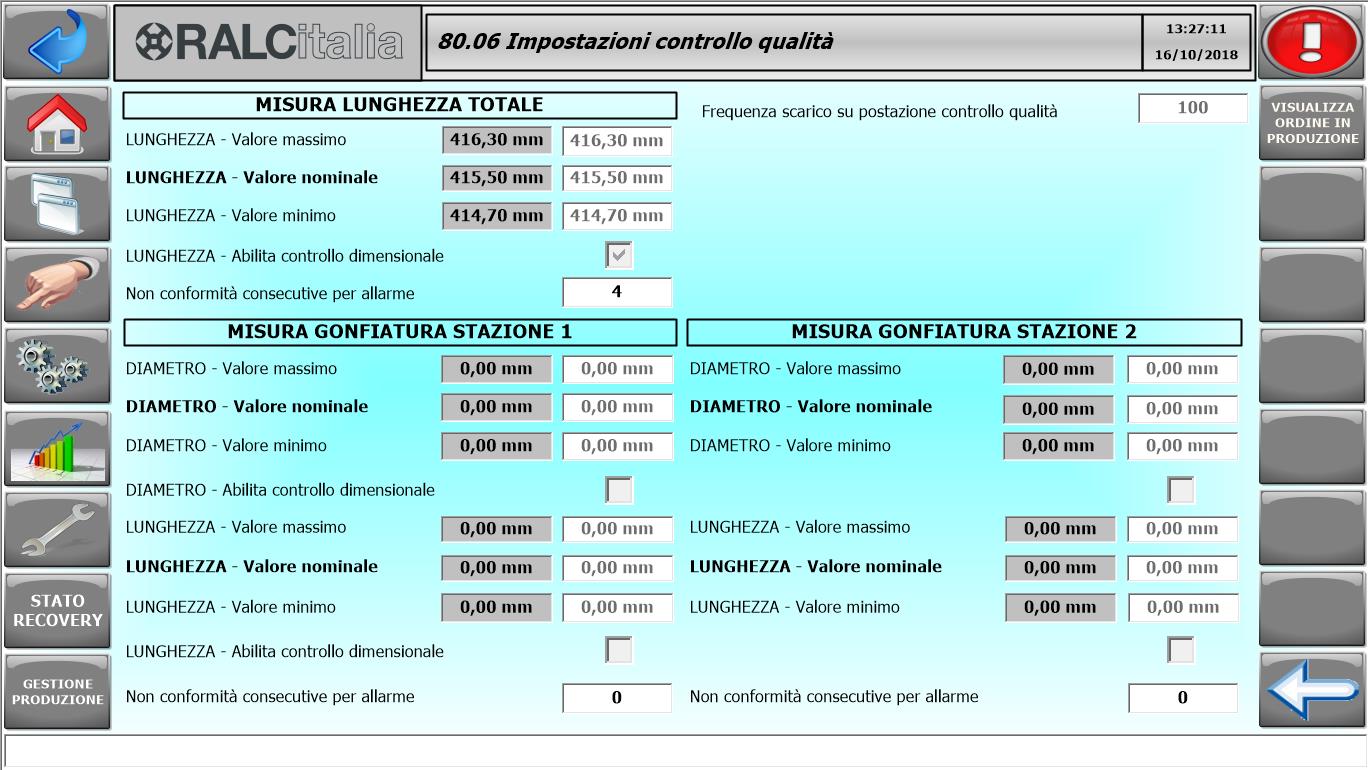

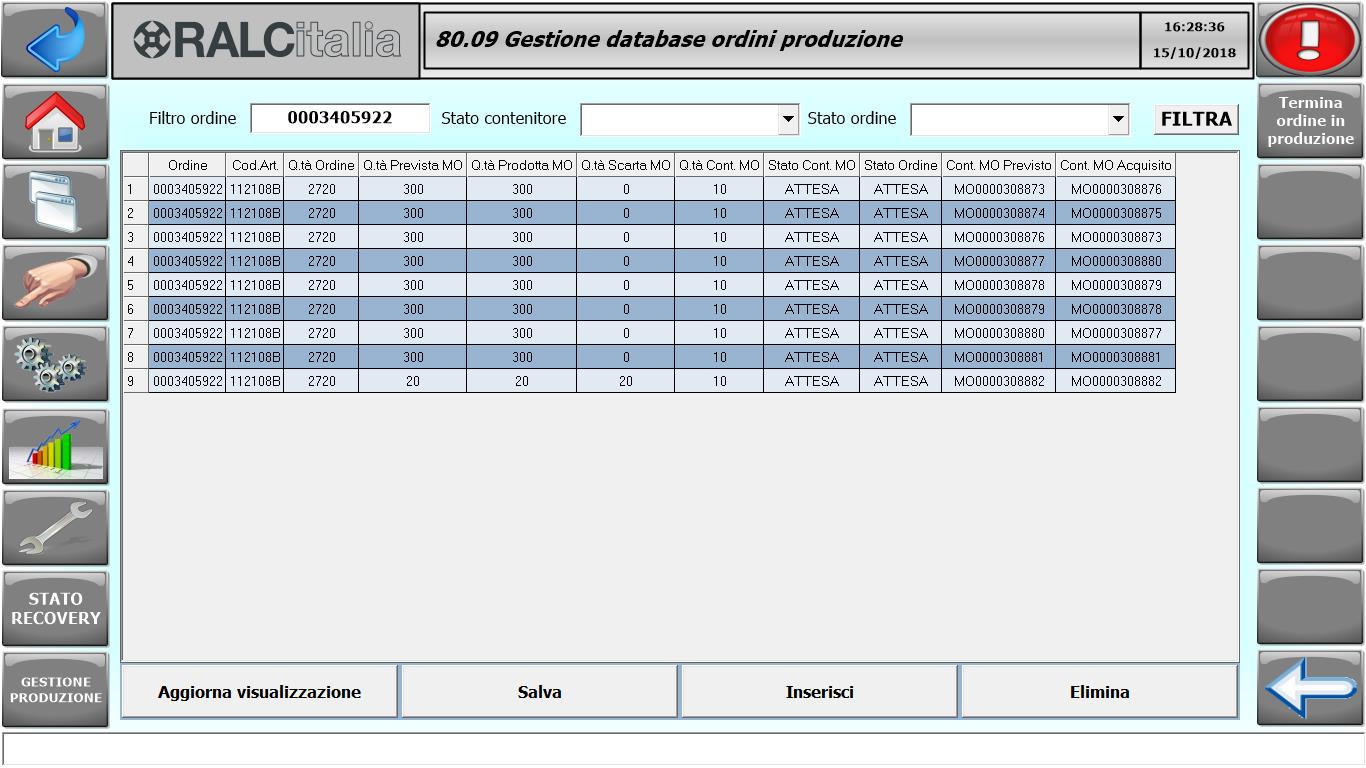

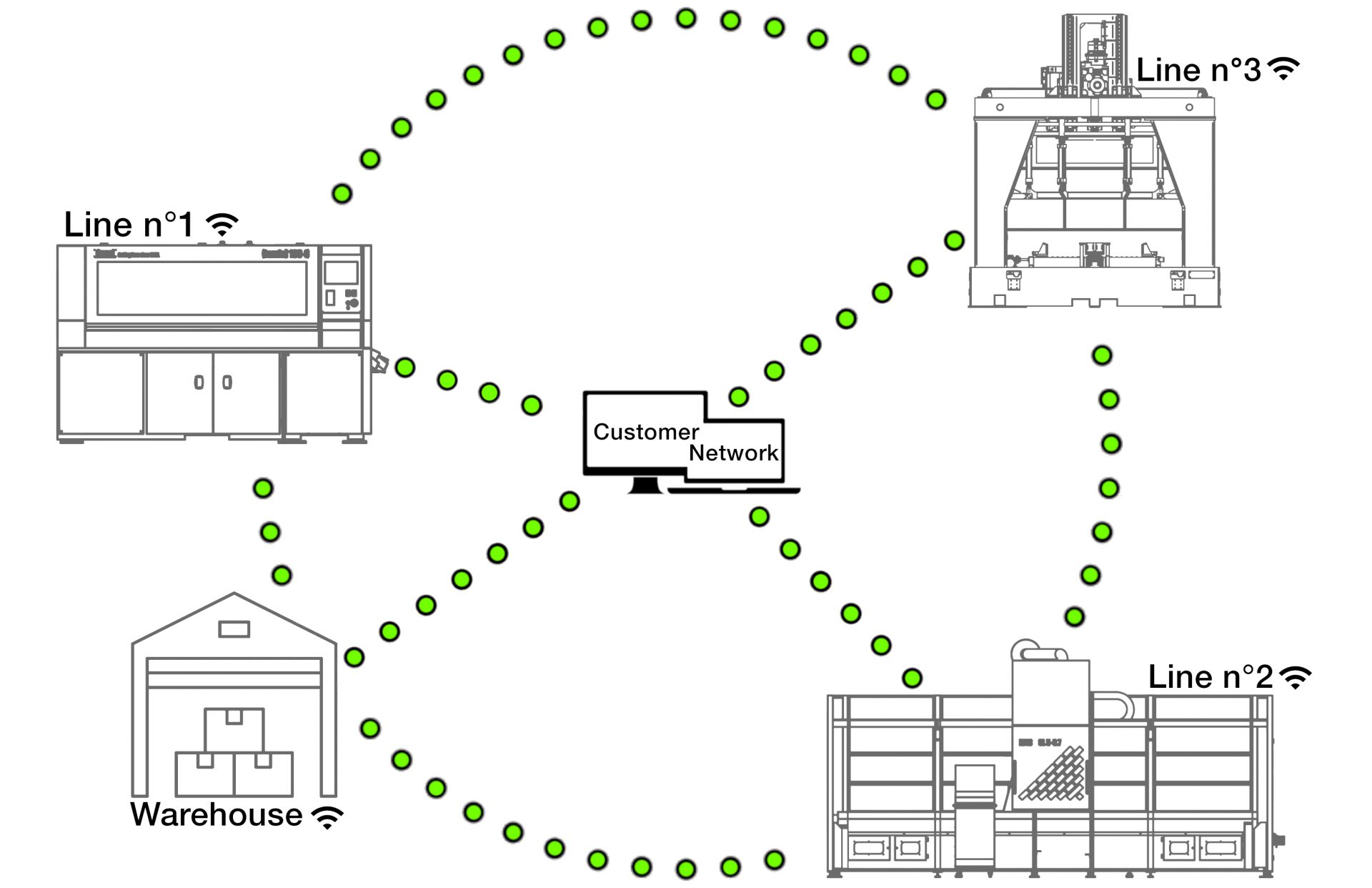

The integrated monitoring of multiple production systems guarantees constant and accurate control of one or more systems. It is therefore possible to optimise and program processes, as well as evaluate performance and output indexes.

Using the “Office programming” module, you can simply import your work orders and the machine tool will be ready to go: a simple tap by the operator and production starts.

The integration and exchange of information between machine tools and external company systems allows you to manage materials in real time, as well as plan and report on production batches and stock.

Monitors, optimises and manages power consumption, creating higher performing systems and reducing waste; data analysis allows predictive maintenance and prevents system downtime.

In addition to the advantage of offering technologically advanced, efficient, and absolutely high-performing machines, factory 4.0 allows mechanical engineering companies to benefit from significant tax concessions and economic incentives provided for by the Italian government.

Want more information?

Write to info@ralcitalia.com