“Technology that gives shape to your ideas”.

EXPERTISE

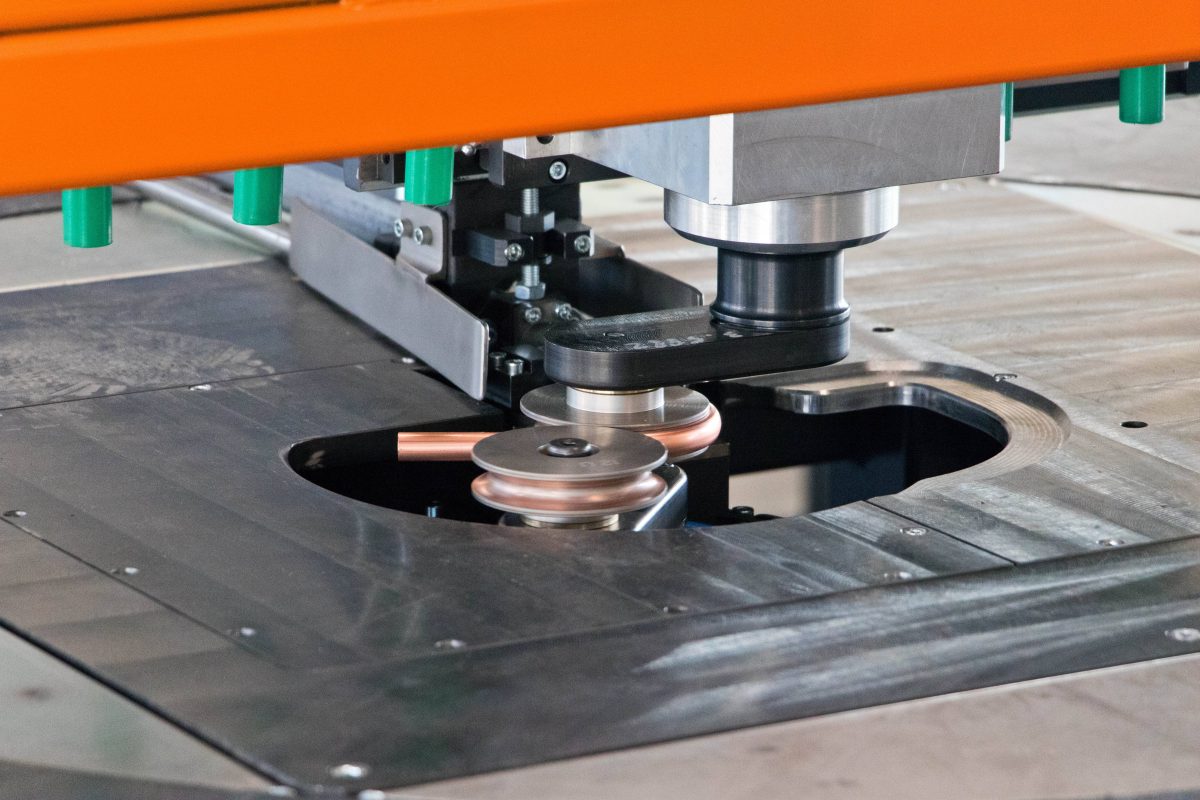

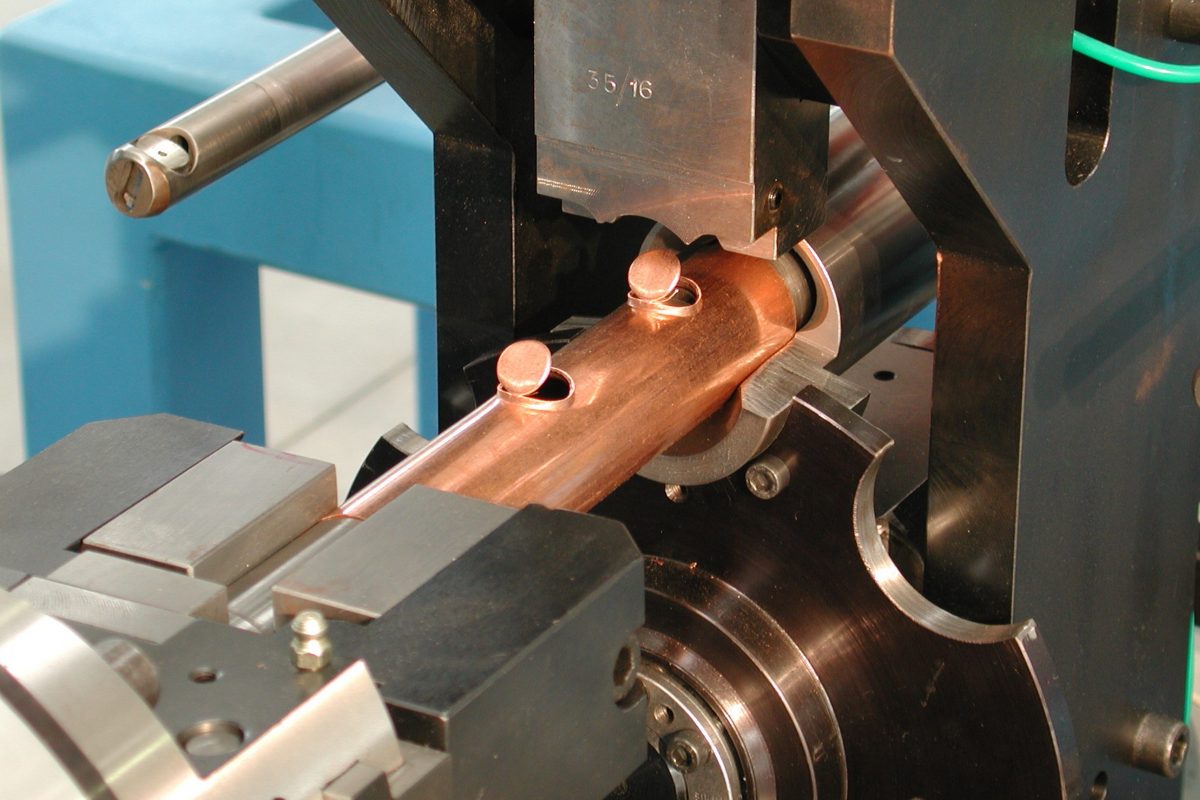

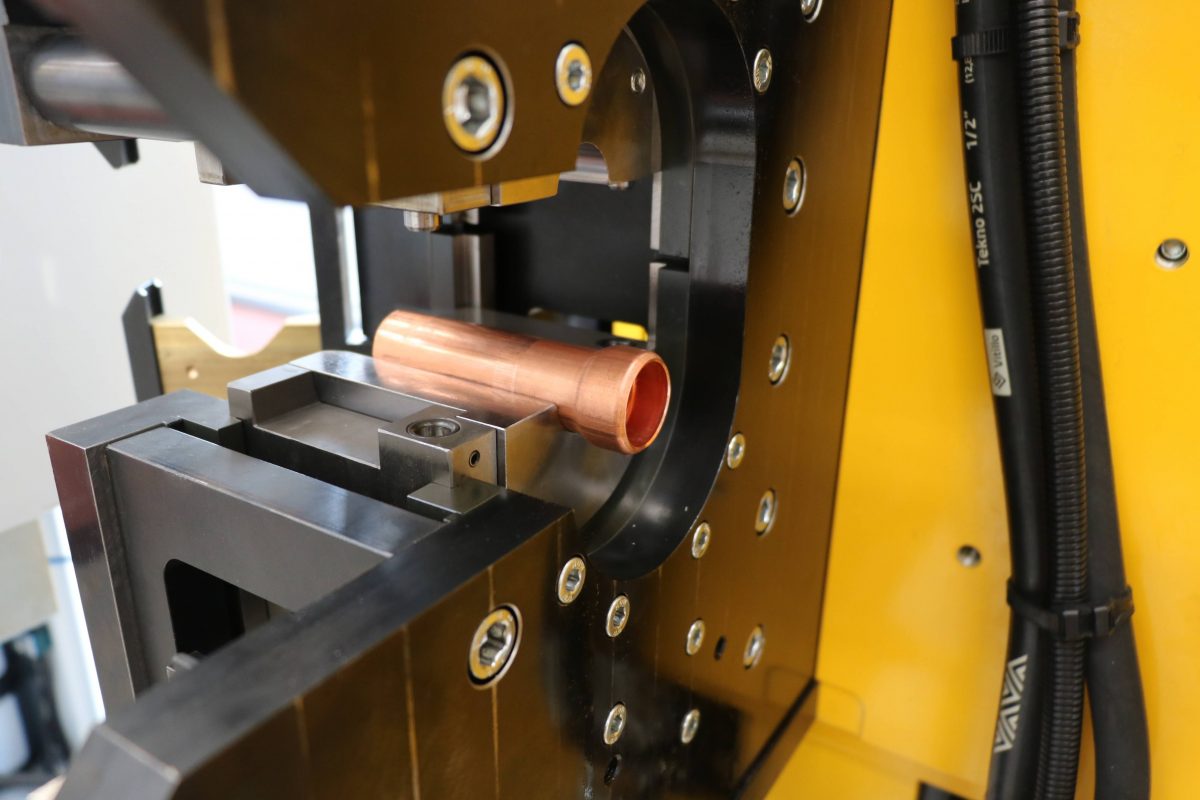

The machining of copper pipes in various diameters with minimal thickness, specifically in the refrigeration sector (HVAC), is Ralc Italia’s most “historical and traditional” core business.

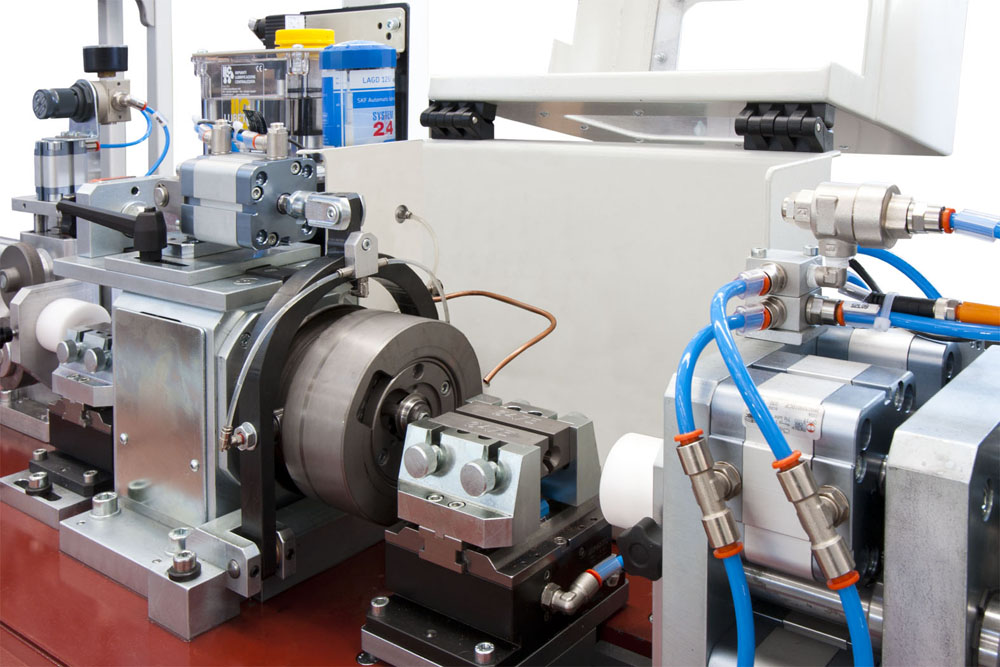

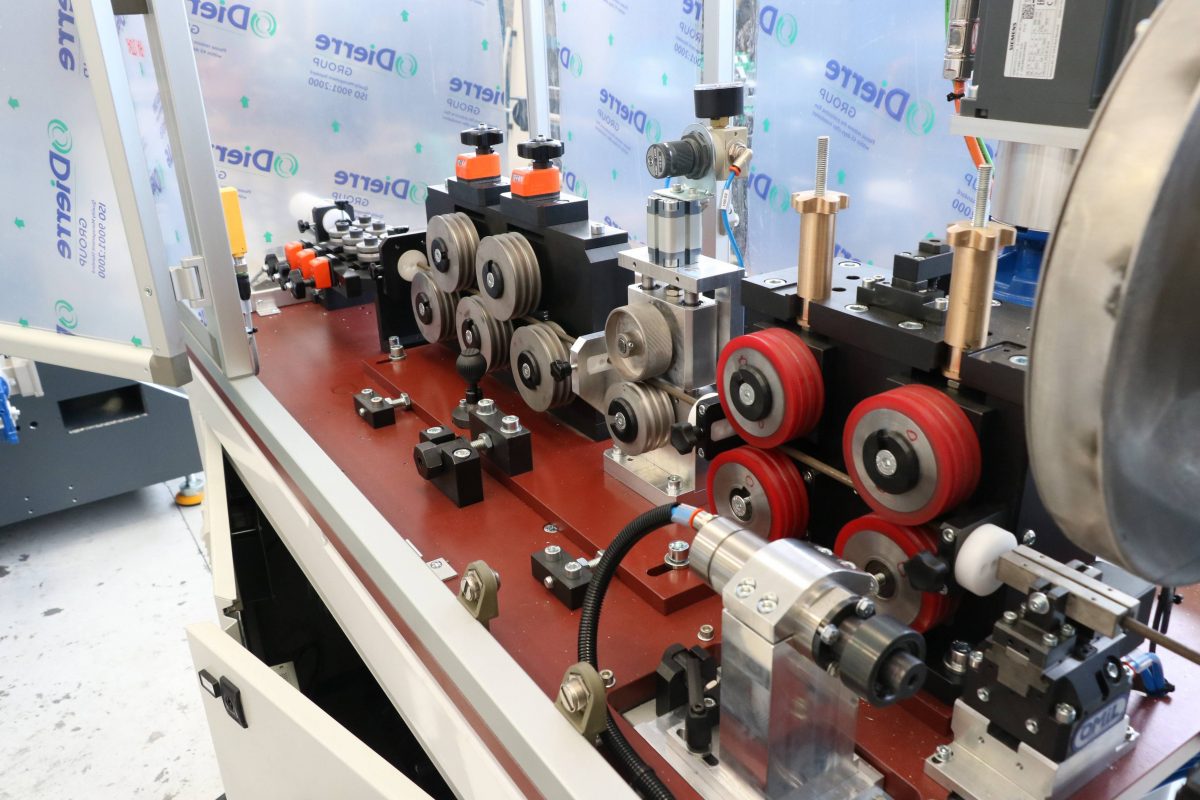

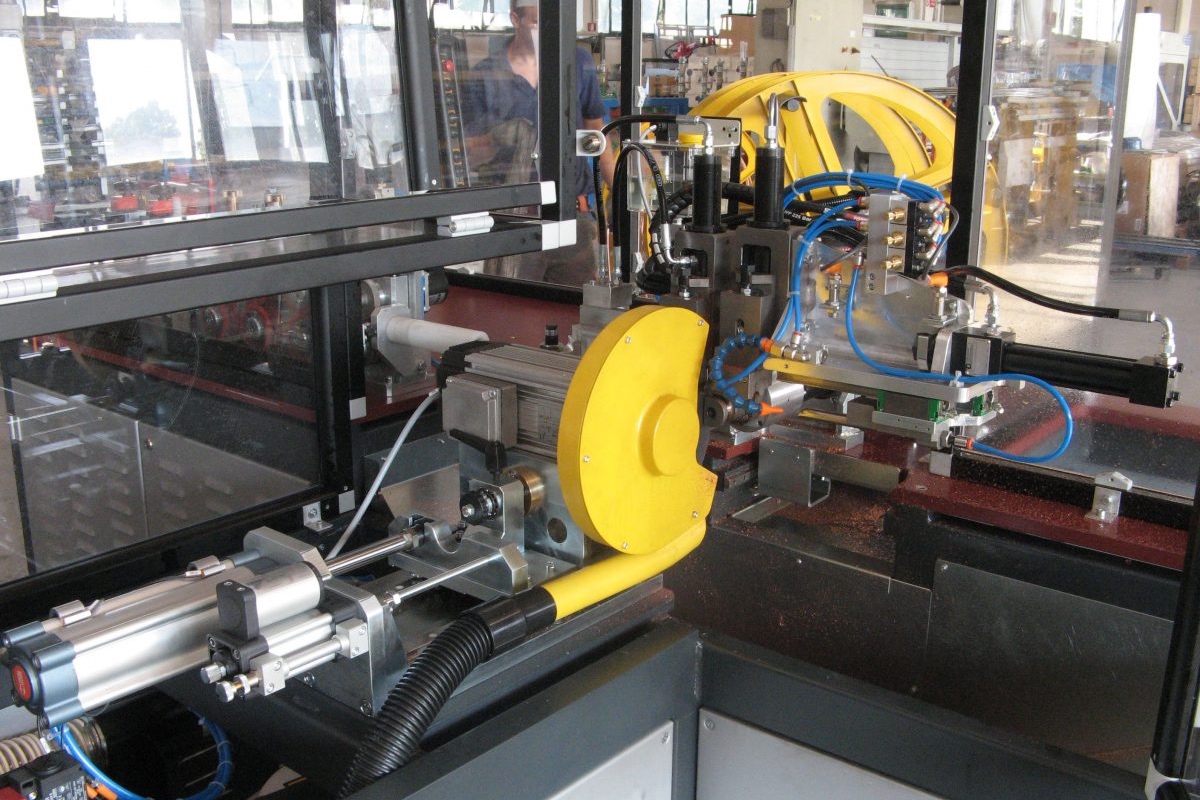

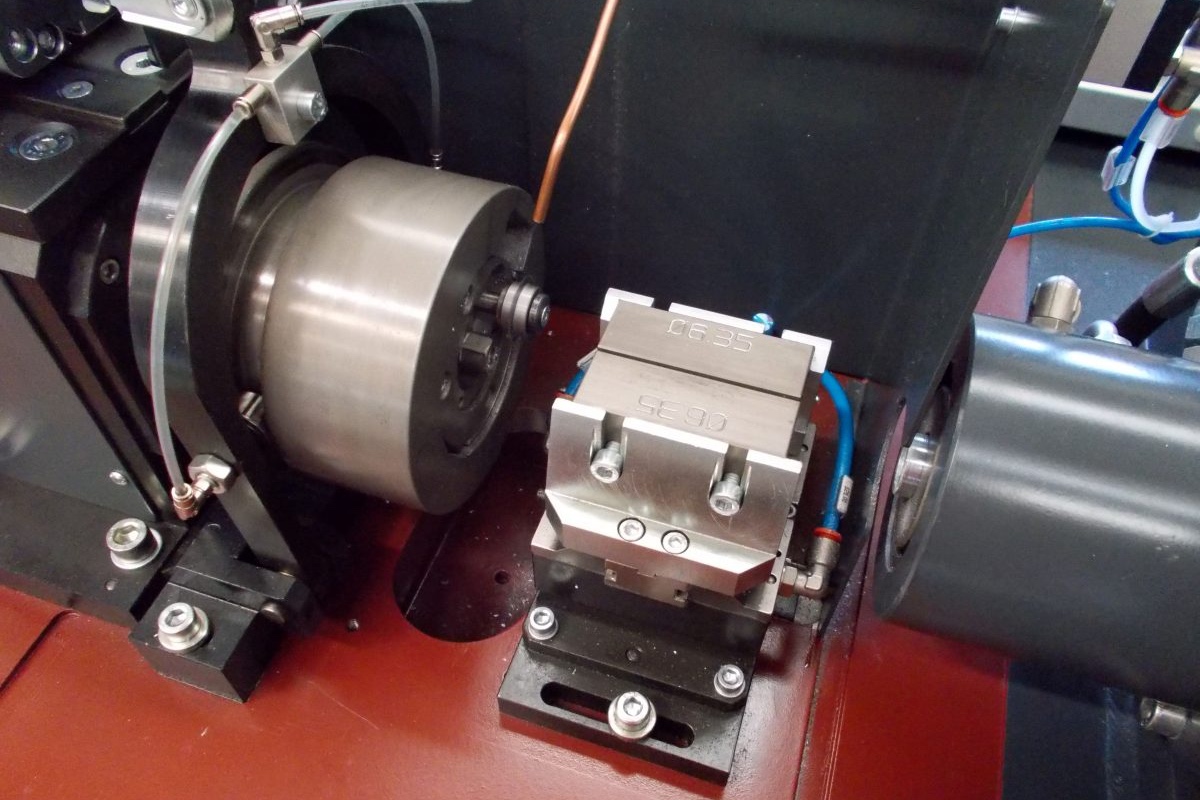

Since its founding back in 1991, Ralc Italia has in fact been committed to the design and construction of systems with varying complexity for orbital cutting, end forming, serpentine bending, nipples and elbows, as well as manifold punching.

Initially dedicated to the machining of small-sized copper pipes, the lines subsequently evolved to include the machining of steel, stainless steel and aluminium pipes, also in medium and large sizes.

Thirty years of experience, a modular and varied range are synonymous with guaranteed results insofar as making it possible to choose the best possible solution for your customised system, 100% Made in Italy and perfectly calibrated to suit your technical and production needs, and budget.

Creativity combined with long-standing experience ensure reliability and continuous evolution, essential factors in a market continuously on the lookout for new solutions, while also constituting an important pool of ideas, solutions and innovations for your next system.

Regardless of the system you choose, you will be supplied with a device for remote technical support; you can also complete the line with a customised 4.0 package.

FEEDING SYSTEMS

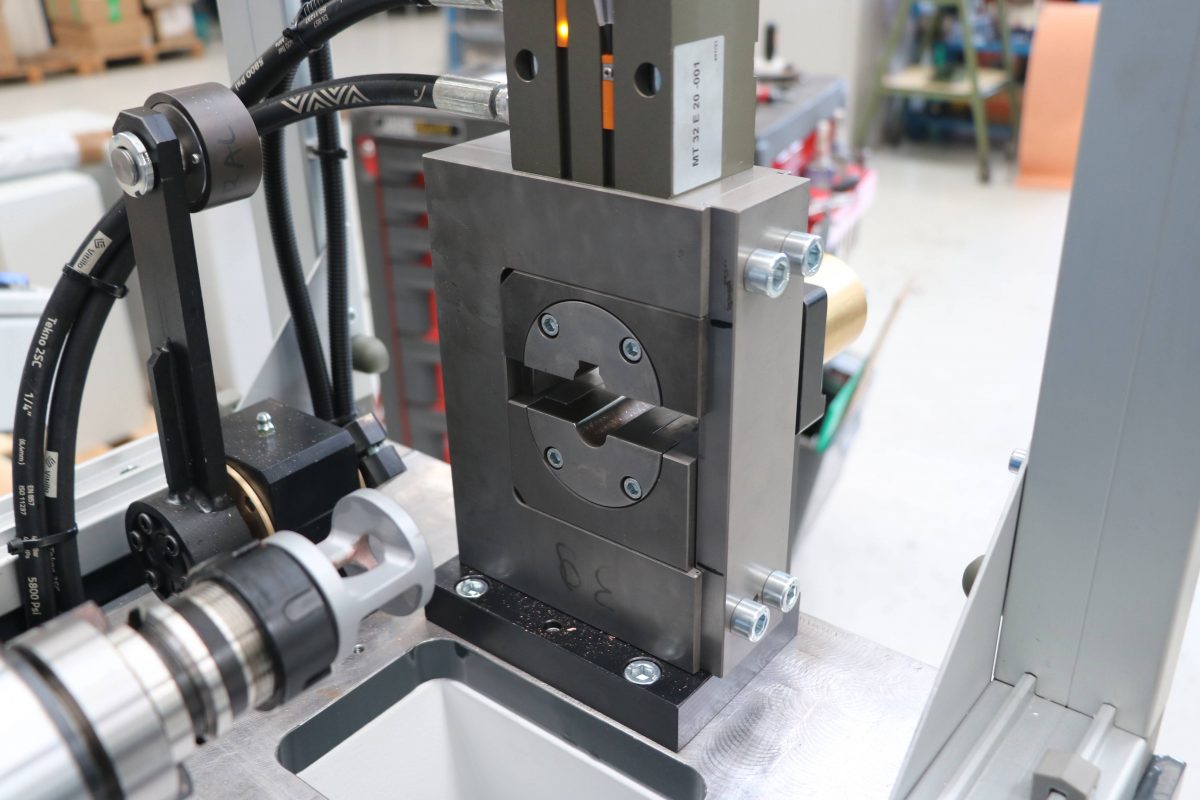

Different loading and unloading solutions are available depending on the application. Unwinders are ideal for coils in different sizes and weights, while the slide or bundle loaders are the perfect solution when working from rod. Machines designed for manual loading can then be fully automated with robotic or other solutions.

Economical, practical, versatile, allows the unloading of short pieces into a container.

Separates the machined pieces from the scrap and deposits them into a small collector without damaging them. Perfect for medium-length pieces.

The belts lower progressively and, once the number of pieces set on the panel has been reached, the operator only has to strap the bundle and unload it. Ideal for long pieces.