Interiors speak. Rooms emphasise whether one exists or lives, and there is a great difference between the two. (Van DayTruex)

In our daily life we continually and often unknowingly use steel elements: our chairs, stairs and tables. Behind these apparently trivial objects lies a careful study of materials, design, practicality, which leaves nothing to chance. Have you ever experienced the annoyance of an unstable table or chair? The difference lies in the machine used to cut the tubes making up the frame. Our clients taught us this.

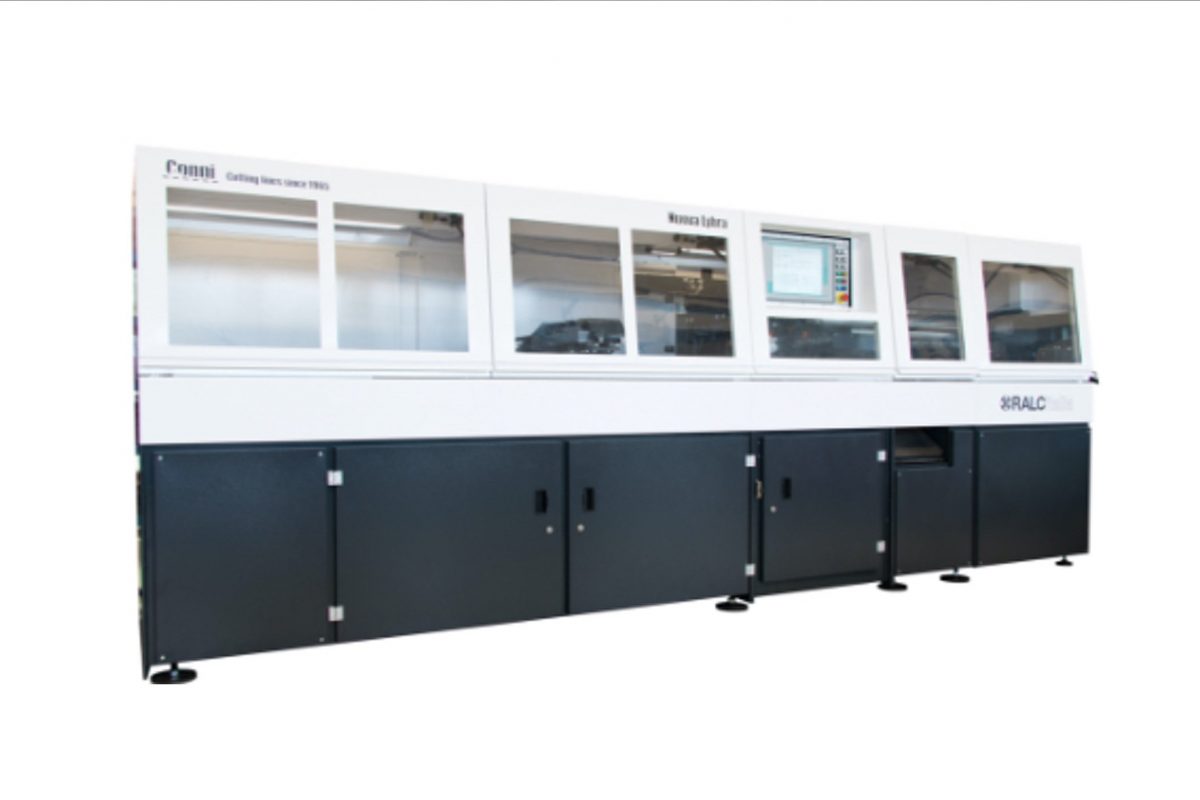

Ralc Italia automations for the furniture manufacturing sector are used all throughout Italy and Europe to guarantee perfect tables and chairs for all our clients.

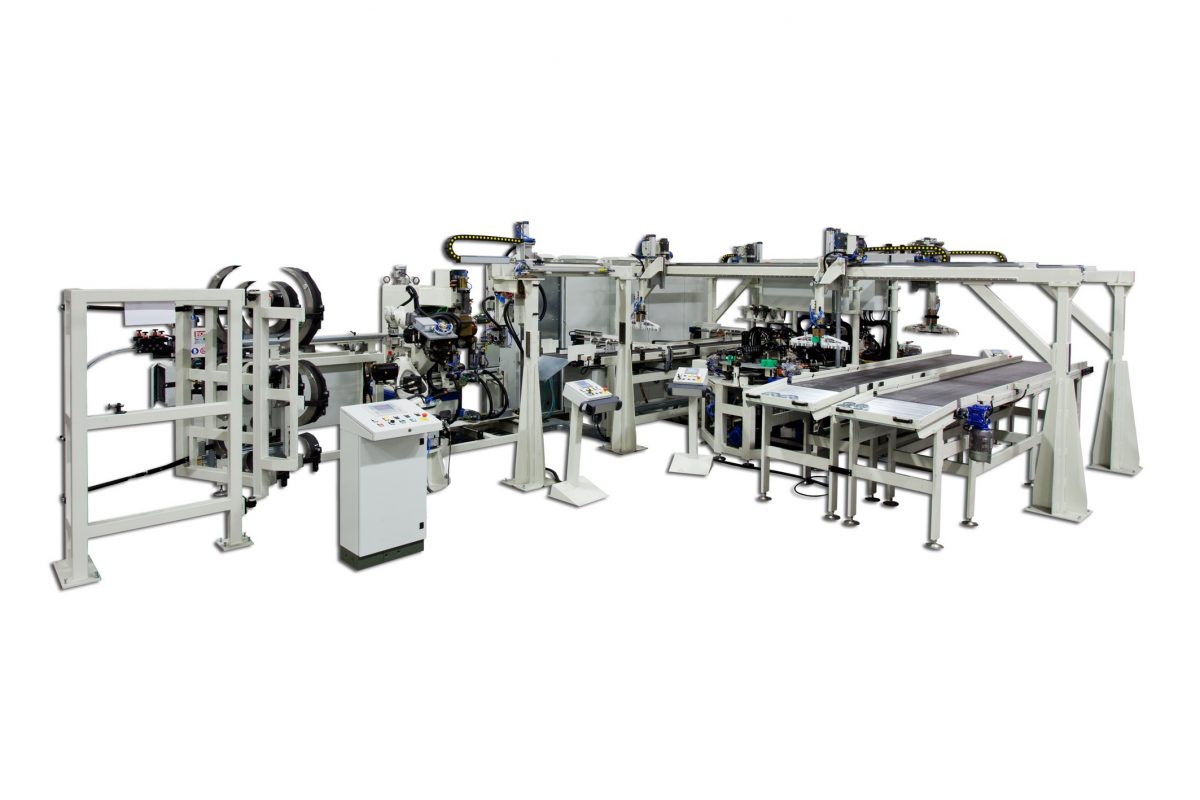

Ralc Italia can provide ad hoc solutions for the manipulation, the welding and the sheet processing.