Special lines for assembly, machining, control.

No surprises

There’s no improvising when it comes to building a special line: to be sure of the result, every choice needs to be carefully assessed, and to do so it takes years of experience, sacrifice and trials. Ralc Italia has been building special machines for 30 years and has gained a wealth of important expertise and solutions for all types of production, material, and machining needs.

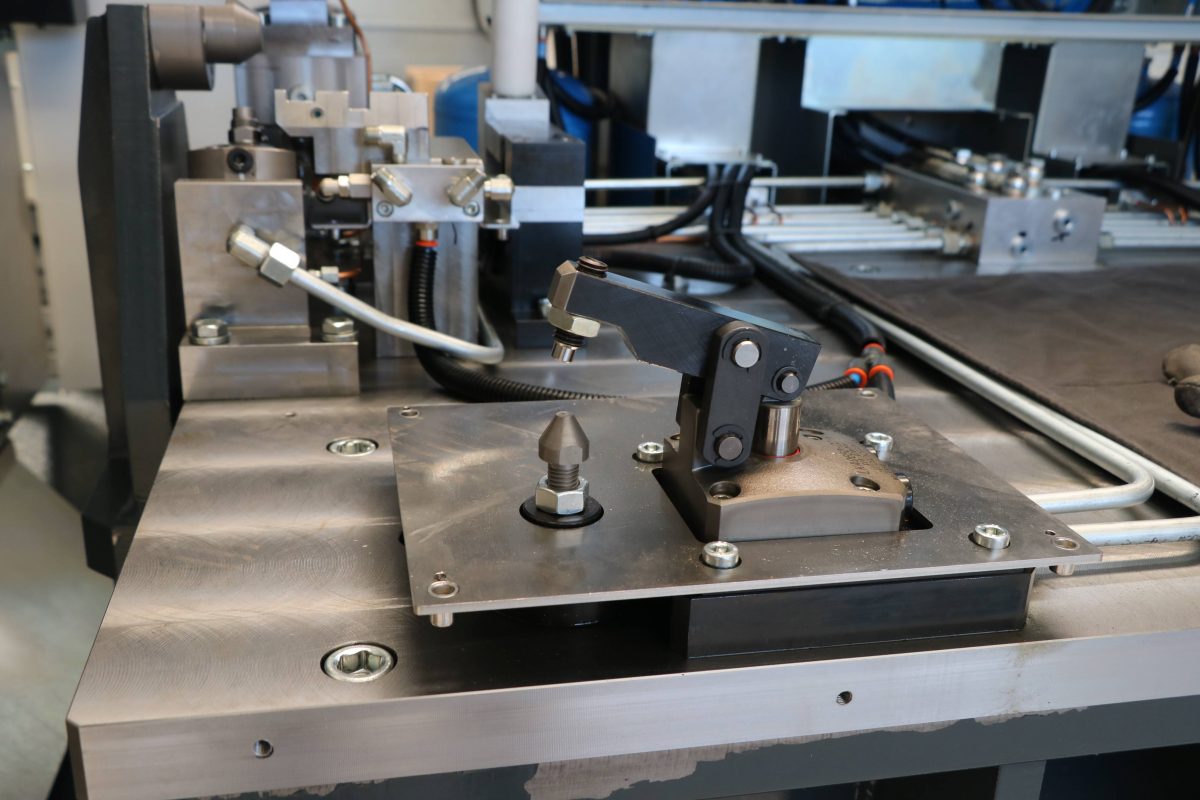

Whatever the type of line, you can rely on knowledgeable, attentive and critical, mechanical, electrical and electronic design: everything is done in-house. Materials and components are suitably sized for the specific application, and very carefully selected from only the best quality manufacturers and suppliers. The structures are sturdy, solid, synonymous with durability. The line is supplied “turnkey”: complete with safety devices, CE marking, installed and tested.

A special line may require the use of various custom designed parts, and Ralc Italia is able to produce many pieces autonomously and internally with latest generation machinery. This important flexibility allows rapid interfacing between the planning and production departments in order to optimise each and every component, identifying the best and highest performing solution, reducing any waste of time and money, all to the benefit of the client.

Following are several examples our completed lines, some of which include Industry 4.0 applications.

Several images of products developed with special automated lines.