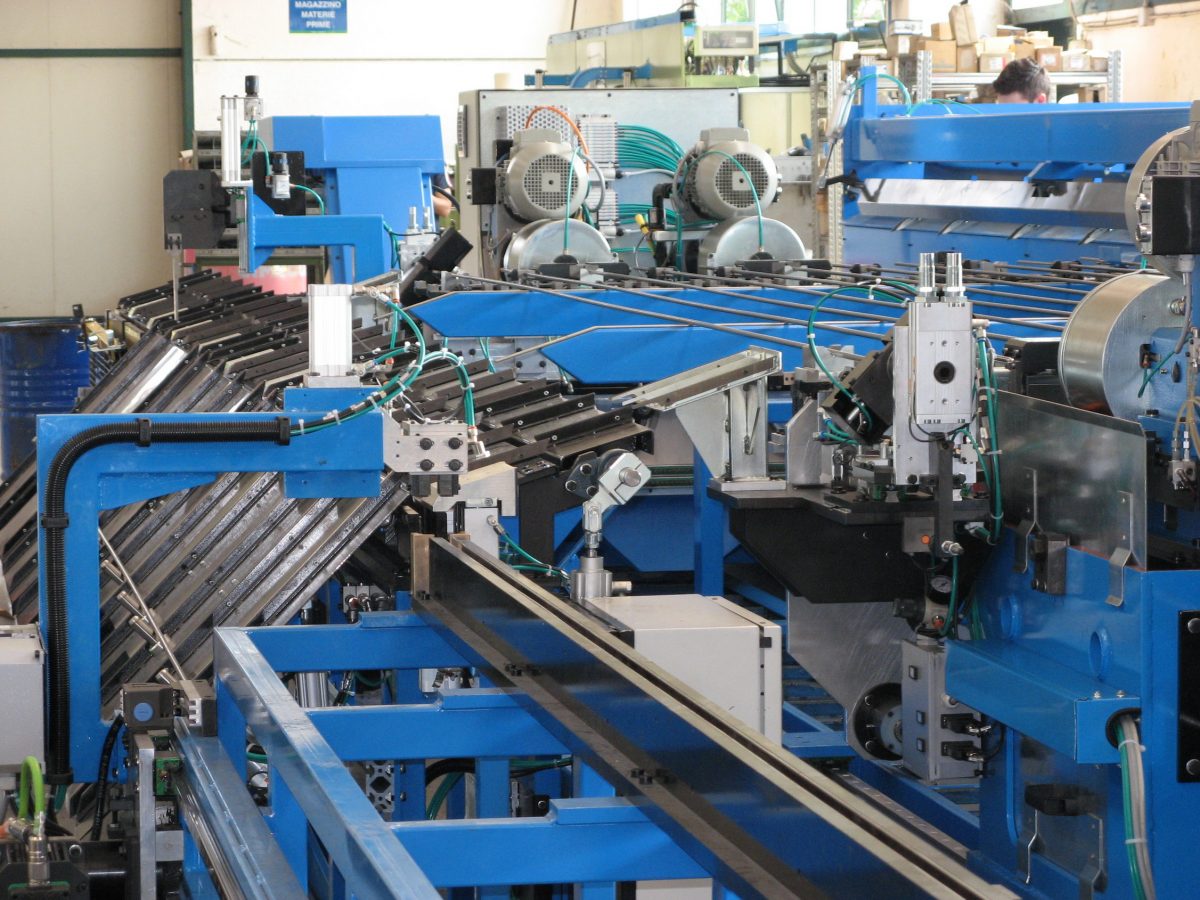

Automated line for the chamfering, turning, threading and bending of prestressed steel rods for high-speed railway line sleepers.

Full automatic

The line for bent bars allows the fully automated production of chamfered, turned, threaded and bent bars. The most renowned steel mills and leading manufacturers of railway sleepers have recognised and rewarded the characteristics of high productivity, repeatability and quality finishing, all essential factors in the production of final products used in high-safety applications.

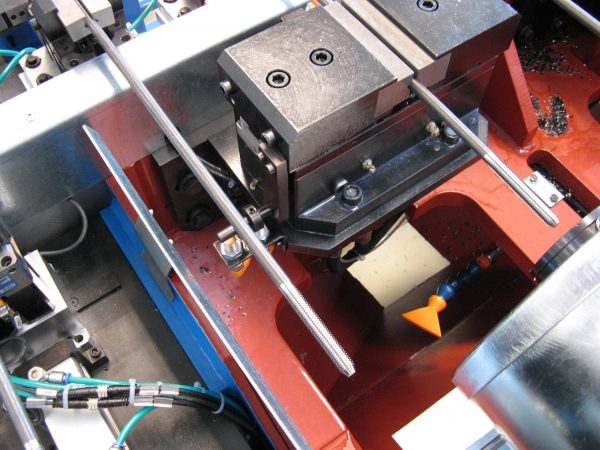

Bent bars in prestressed steel are a certified component, insofar as they must be used in conditions requiring extreme safety and reliability. Therefore, there is no room for compromise on the quality of the finish, precision and repeatability of machining. A measuring system checks the length of the bar before machining, tensioning it to avoid pointless tool wear and time wastage. Non-conforming bars are in fact shifted without being machined in the event their measured length falls outside the set tolerance.

The chamfering, turning, and threading heads are supplied by a leading world manufacturer and machine both ends of the bar simultaneously in two successive stages. They slide on slides driven by brushless motors, allowing the stroke of the units to be adapted to obtain the desired length, while also correcting any errors detected by the length control.

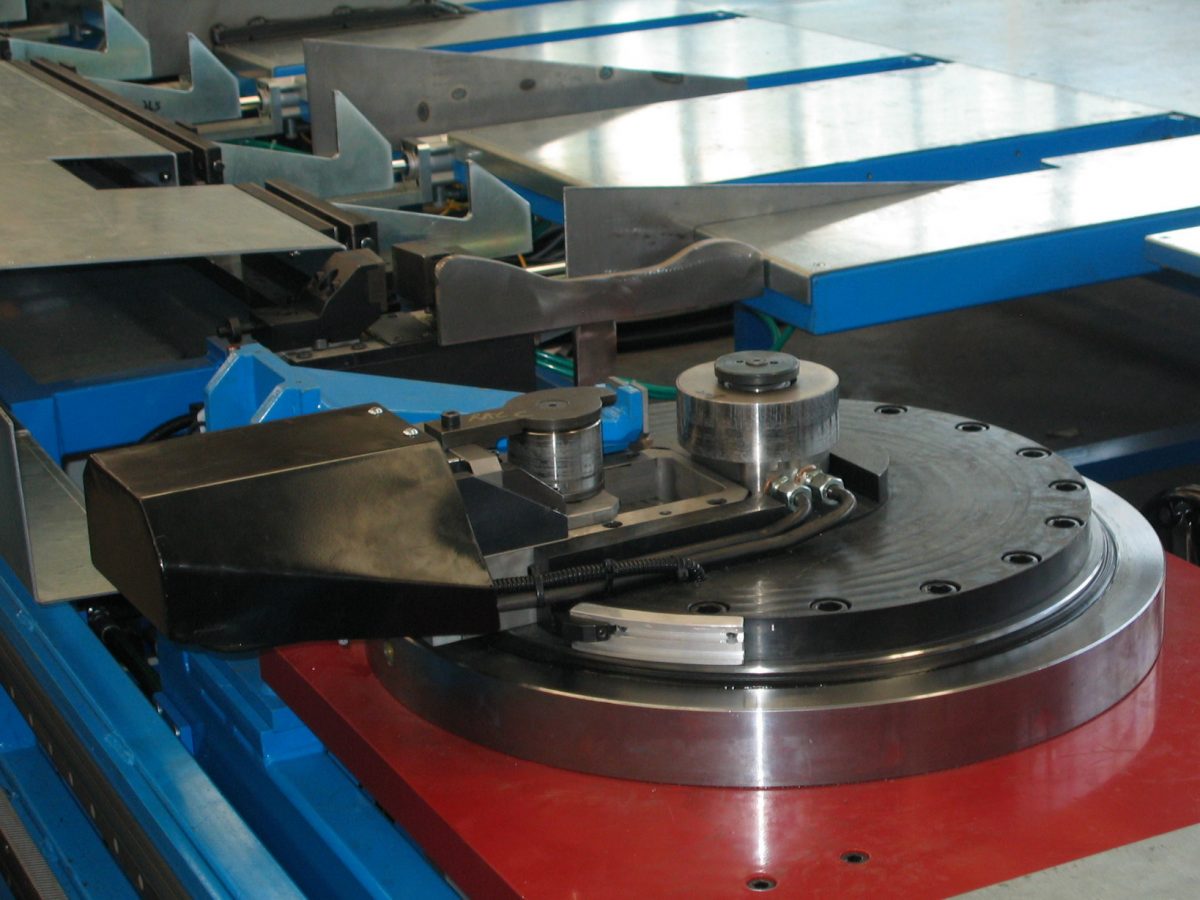

The line can process straight bars, which are unloaded into a dedicated chute, or produce bent rods. In the latter case, two bars are simultaneously aligned and a gripper shifts them up to the bending unit, which bends them at 180°.

Ralc Italia has been developing the bar line for decades, ultimately achieving the current level of perfection allowing excellent results with particularly complex machining.

The gripper transfer system is the ideal solution for transferring bars with length greater than 3,200mm.

For the efficient blocking of the piece during the processing; combined with the ISO40 machining heads by leading world manufacturers, they constitute a further guarantee of precision and repeatability.

The machine is equipped with two measuring stations (one for each end), which check the diameter of the thread in multiple points. The check is made on 100% of the bars, and also allows the plate and roll wear to be checked.

For the evacuation of chips, a suitably sized evacuator is used, complete with a pump to ensure the proper lubrication and cooling of the tools.

A chute located before the piece collection system and after the thread diameter control collects all processing waste (non-conforming length or diameter).

The lubrication is carefully dosed and directed to optimise tool wear during machining, but without contaminating the bar.

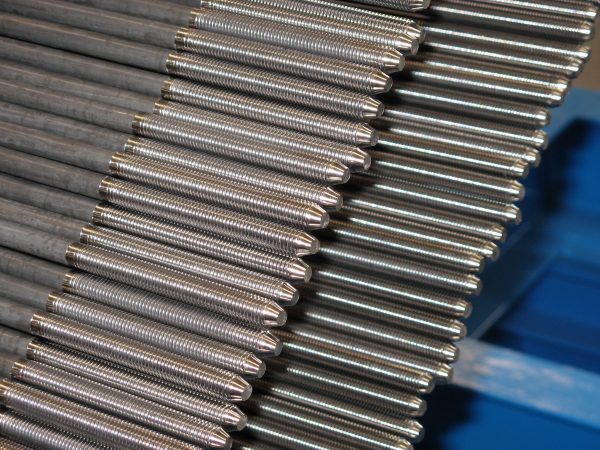

The line produces bars with diameter from 7 to 12.5mm, with maximum thread length 90mm.

The line produces bars with diameter from 7 to 12.5mm, with maximum thread length 90mm.

The line produces bars with diameter from 7 to 12.5mm, with maximum thread length 90mm.

The line produces bars with diameter from 7 to 12.5mm, with maximum thread length 90mm.

The line produces bars with diameter from 7 to 12.5mm, with maximum thread length 90mm.