“30 years of expertise. At your service.”

YOU CAN TRUST US

Those who choose to invest in a special line pursue the objective of automating often burdensome and costly manual processes, and are therefore aiming for guaranteed production advantages. On the flip side, purchasing a special line is a challenging and risky process, insofar as it implicates the need to trust a technological partner, asking them to build something that has never been built before.

30 years of experience in the design and construction of special machines;

Evolved expertise in the main industrial sectors;

Solutions and applications that have already been studied, realised and tested in dozens of lines;

Long-term collaborations with partners able to provide multiple technological solutions;

Use of exclusively high-quality components;

Renowned references all throughout the world;

A single point of contact that speaks multiple languages, from the feasibility study through to installation.

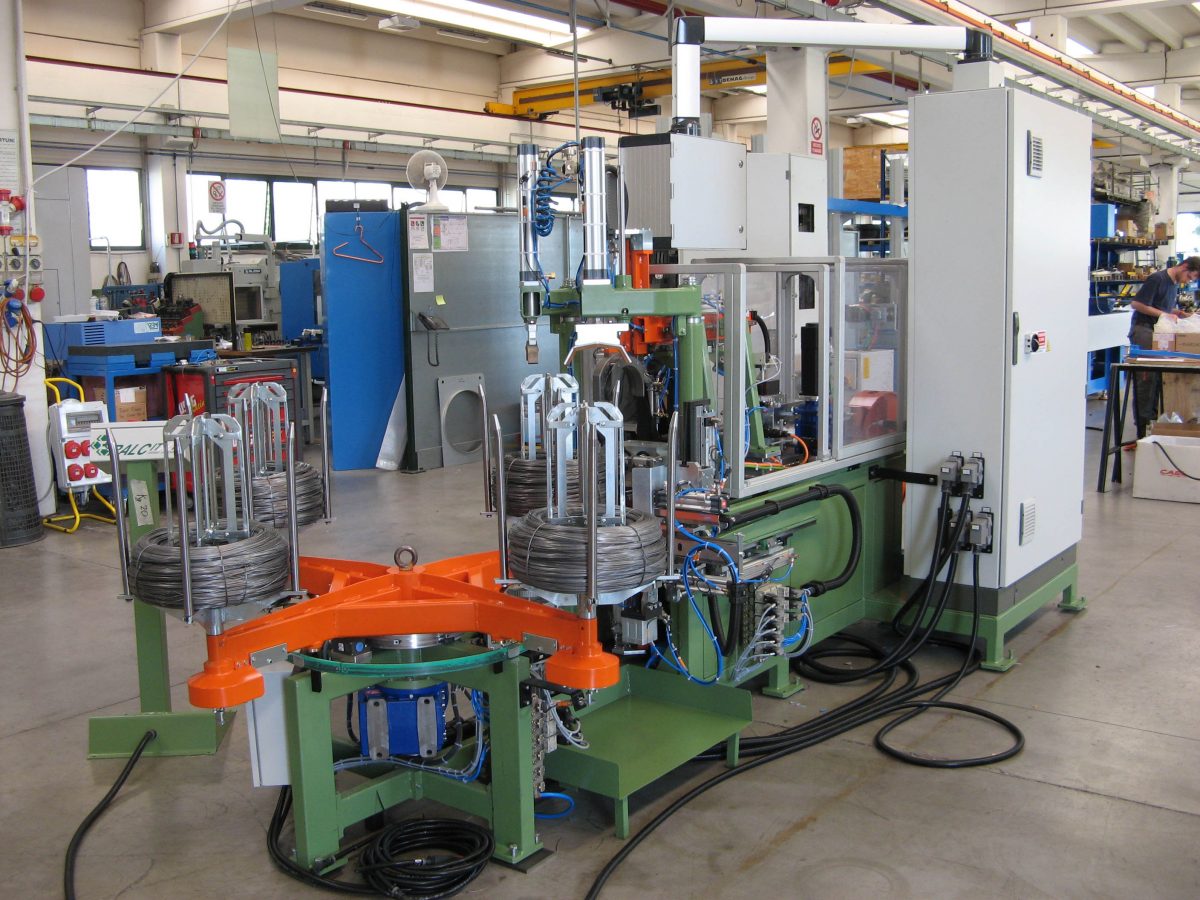

Special lines for assembly, machining, control.

Special lines for assembly, machining, control, strapping.

Ralc Italia has developed special systems for the handling and machining of wire, sheet metal, pipes, including processes such as milling, chamfering, control, welding, forming, assembly. It has the necessary skills for the application of robotic and pick&place technologies. Following are several examples of completed applications.

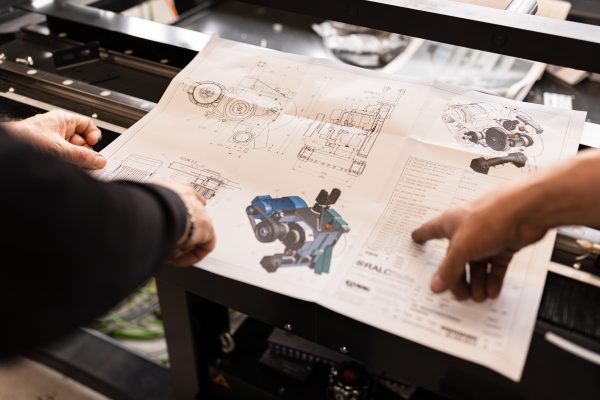

Everything starts by listening to the client’s needs, carrying out site visits at their facility in the presence of the engineering team that follows the design development. It is proactive listening insofar as once the client’s needs have been carefully heard, studies, case histories and previous experiences are offered up, constituting a starting point and basis for ideas to then guide the client towards the most suitable level of automation.

Thanks to Ralc Italia’s long-standing experience, it won’t be like taking a leap in the dark, but rather a case of sharing, where possible, tangible experiences, highlighting the pros and cons of each solution.

To describe the proposed solutions and agreements made, with all the necessary revisions needed to define the best solution before placing the order.

The client is actively involved in all stages of planning, with periodic revisions of the design, which in coming to life, acquires an increasing level of detail.

A team of expert installers with many years of experience and access to the best possible equipment will leave no detail to chance.

Our technicians will carry out functional testing in the presence of the client and provide the necessary training.

Our support technicians will be available, both by remote and at the client premises, for the entire life of the line.