“There isn’t a train I wouldn’t take, no matter where it’s going.” (Nancy Boyd)

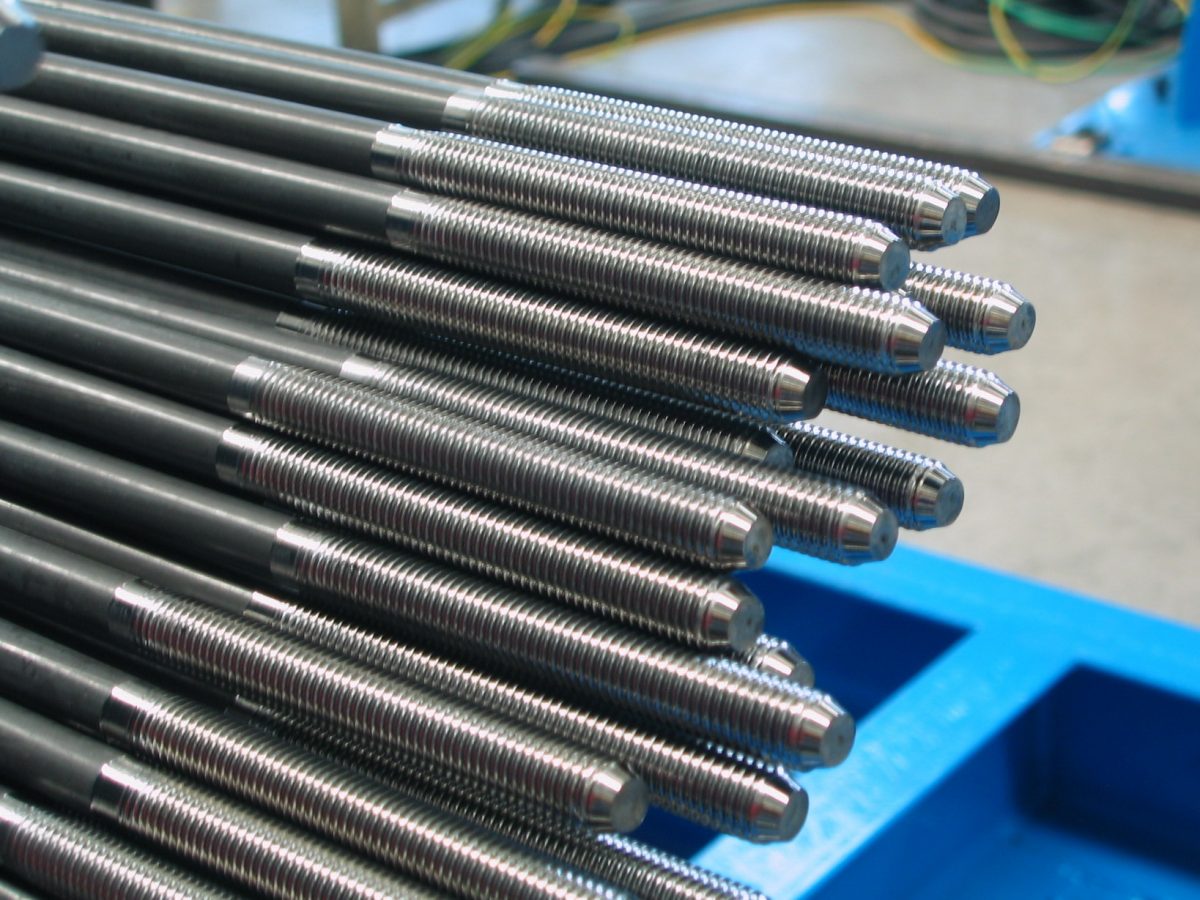

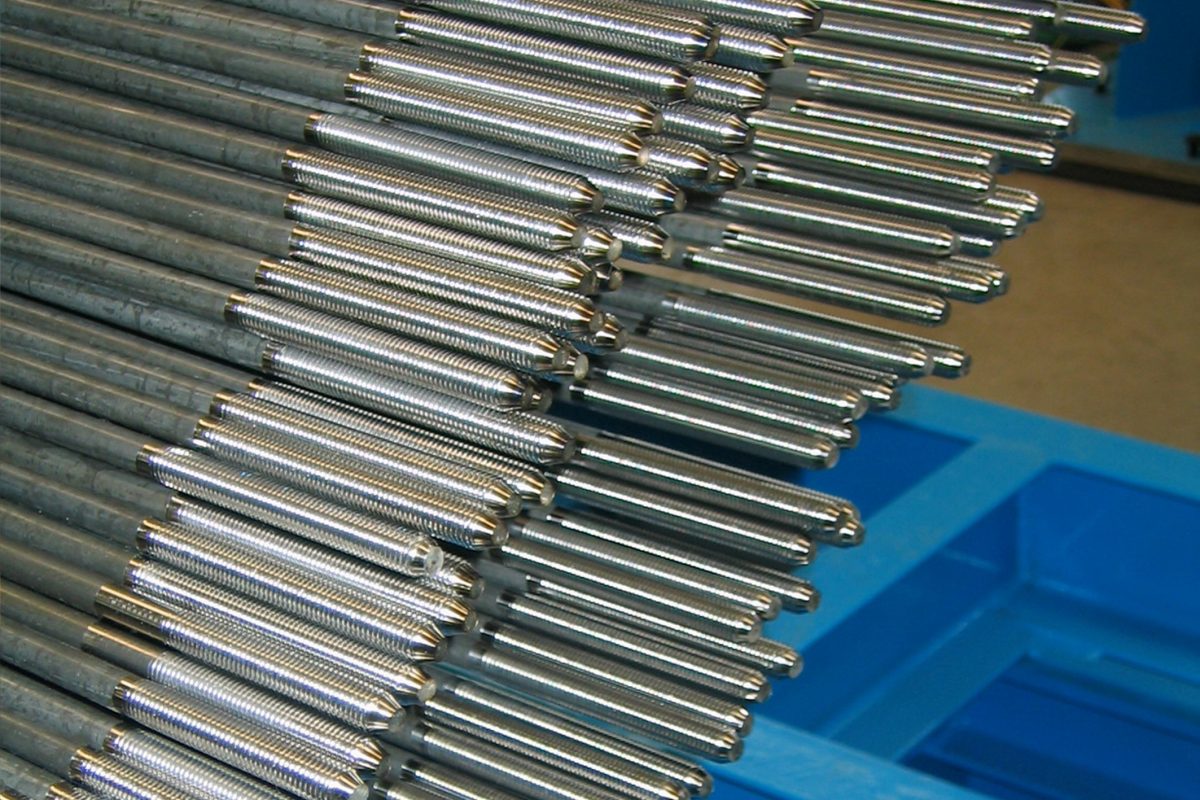

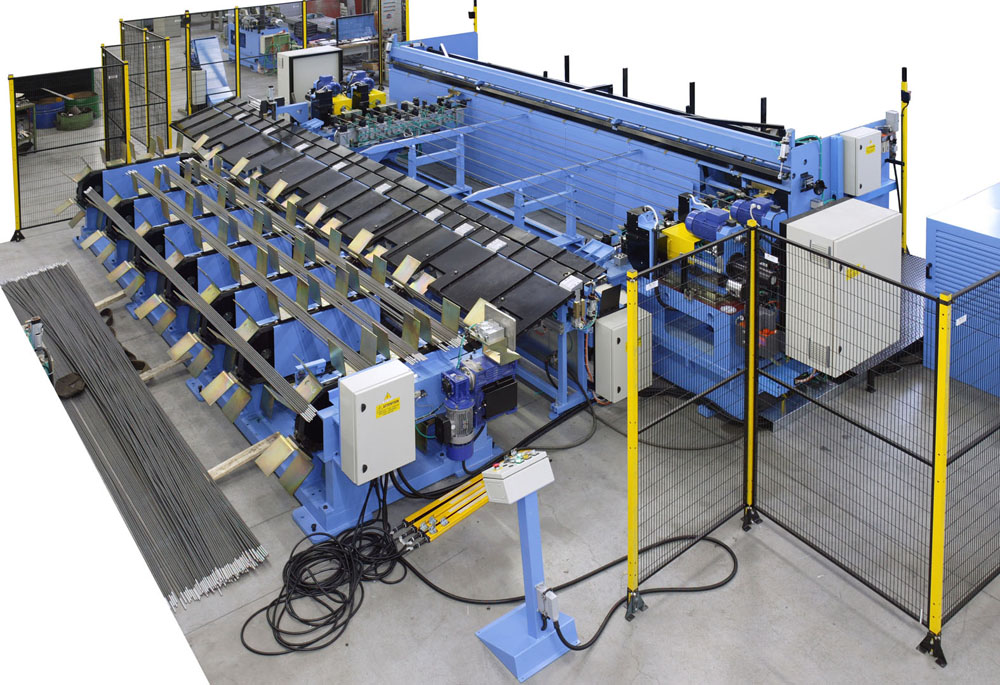

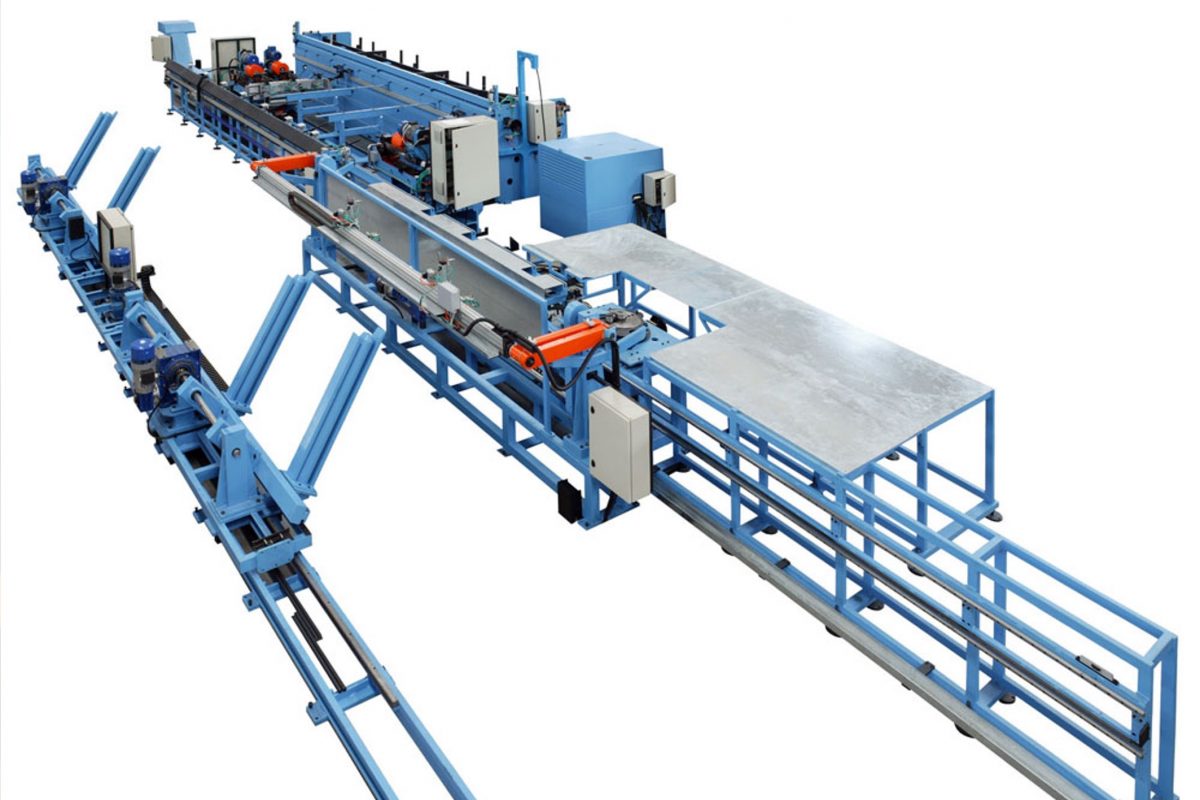

The railway sector is particularly dear to Ralc Italia: this sector is in fact where the bar line is used, a true benchmark for major worldwide manufacturers and suppliers of high-speed railway sleepers. A safety component subject to very strict testing, which must satisfy essential requirements of tolerance and repeatability, but also important demands in terms of volumes.

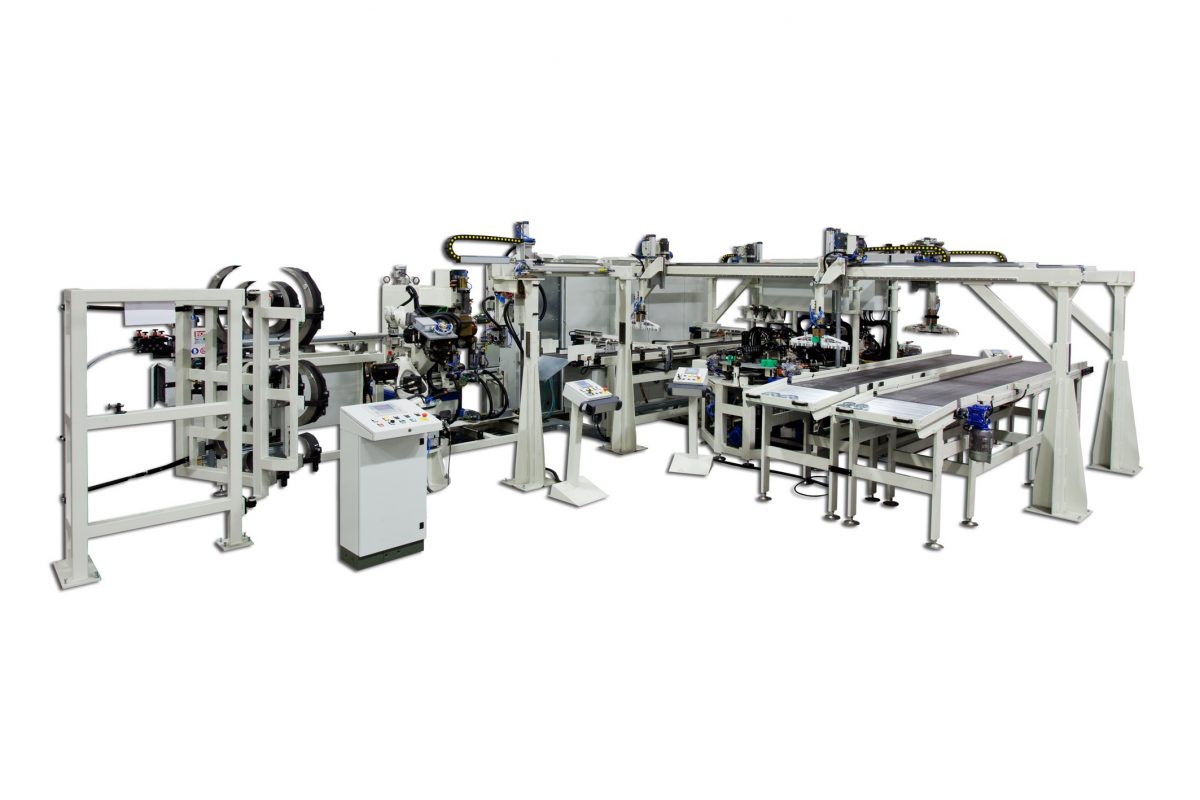

Ralc Italia has sold automated lines to major manufacturers and suppliers of high-speed railway sleepers, becoming a point of reference in this sector thanks to the productivity, reliability and precision of its bar line. The machining centres on the other hand are used to machine the train bodies.

Ralc Italia can provide ad hoc solutions for the manipulation, the welding and the sheet processing.