“Recognising the need is the primary condition for design.” (Charles Eames)

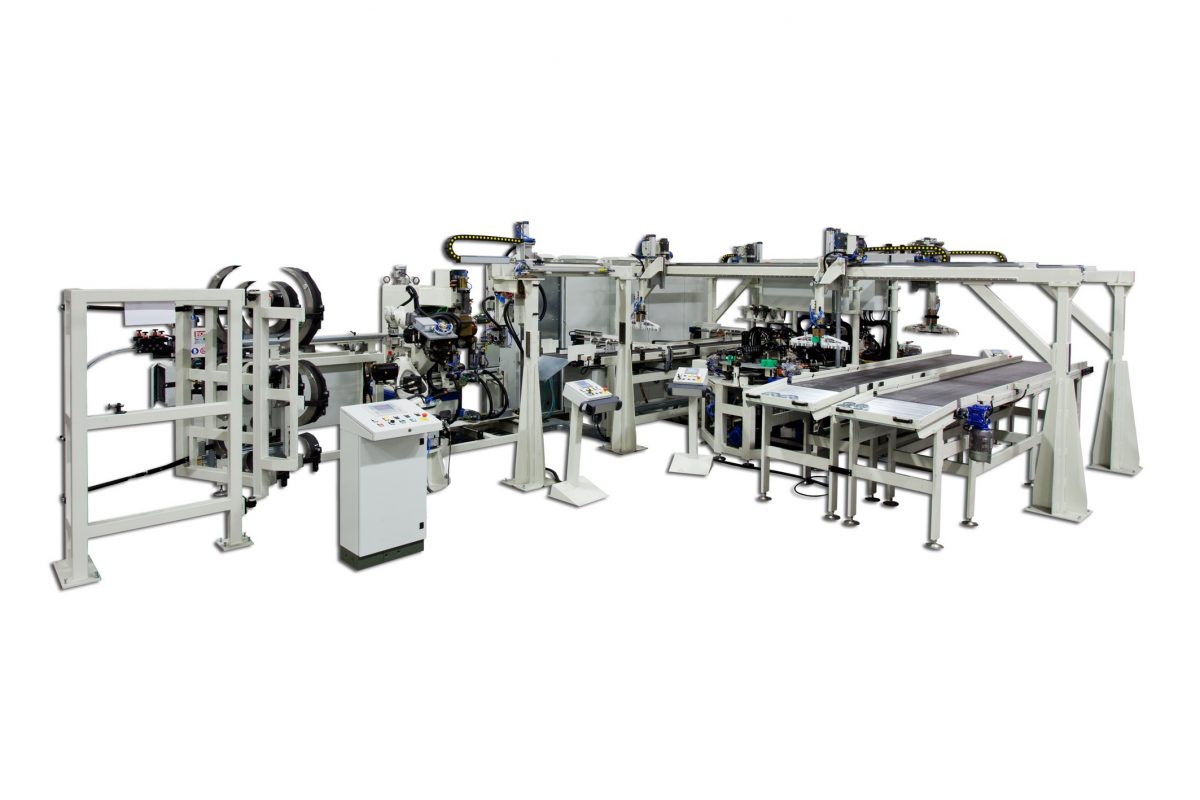

Radiators, taps, towel rails… once upon a time they were merely functional, but today they also need to furnish our homes. While the production of moulded fittings requires highly productive, precise and repetitive lines, the lines for furniture components need to be extremely versatile and guarantee high-quality finishes with zero surface damage.

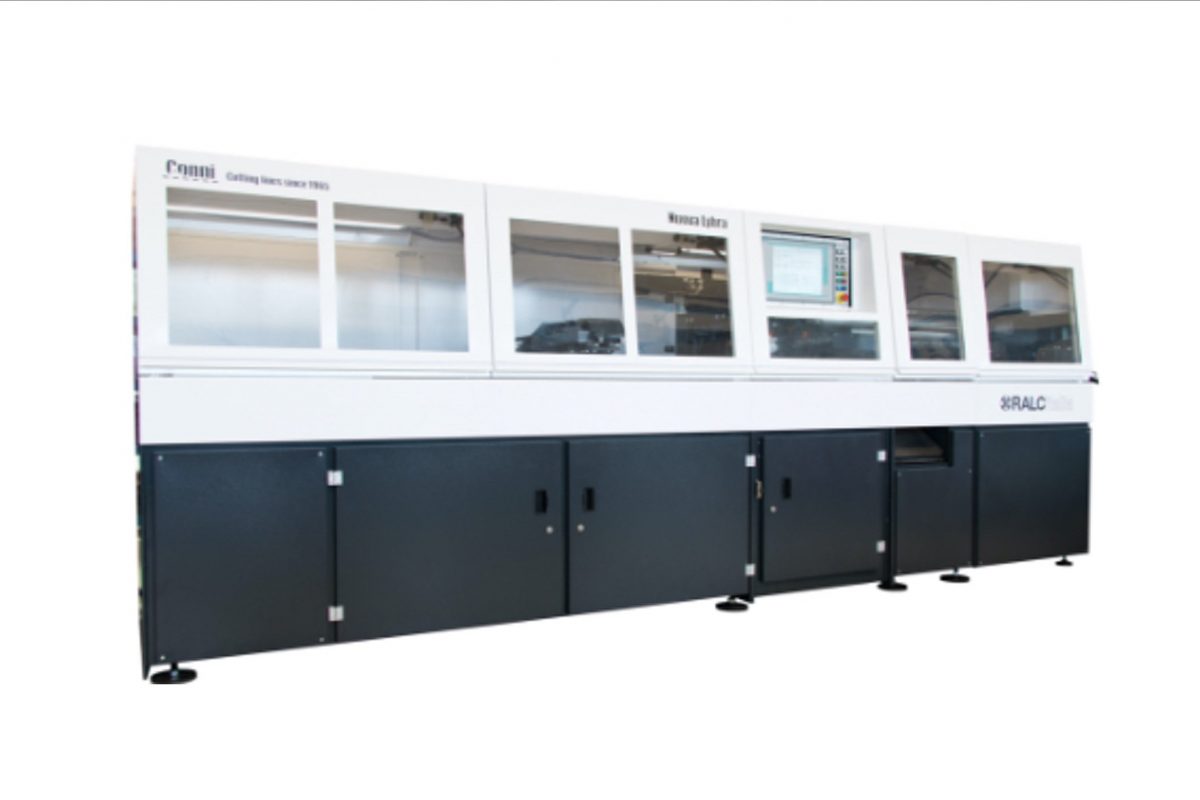

Ralc Italia has extremely productive and precise lines that satisfy all the functional requirements of the moulding and fitting sector, including weight-based cutting. Moreover, it proposes various lines for the processing of furnishing components in steel.

Ralc Italia can provide ad hoc solutions for the manipulation, the welding and the sheet processing.