“We look to the future with trust because we're backed by great tradition”.

EXPERTISE

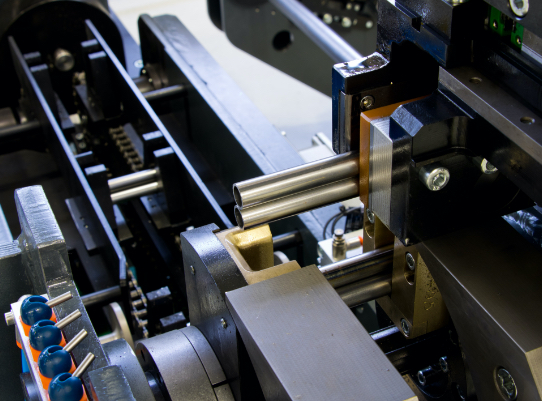

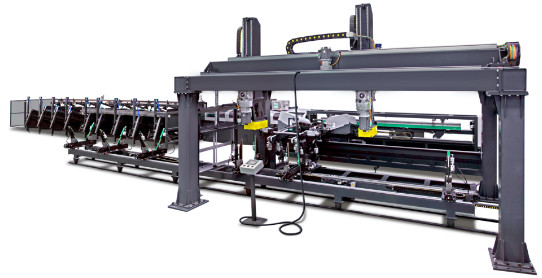

With more than 55 years of experience in the construction of automatic circular saw cutting systems, Conni Cutting Lines has been a Ralc Italia brand since 2012. All Conni-Ralc Italia cutting lines are equipped with automatic and modular loading and unloading systems.

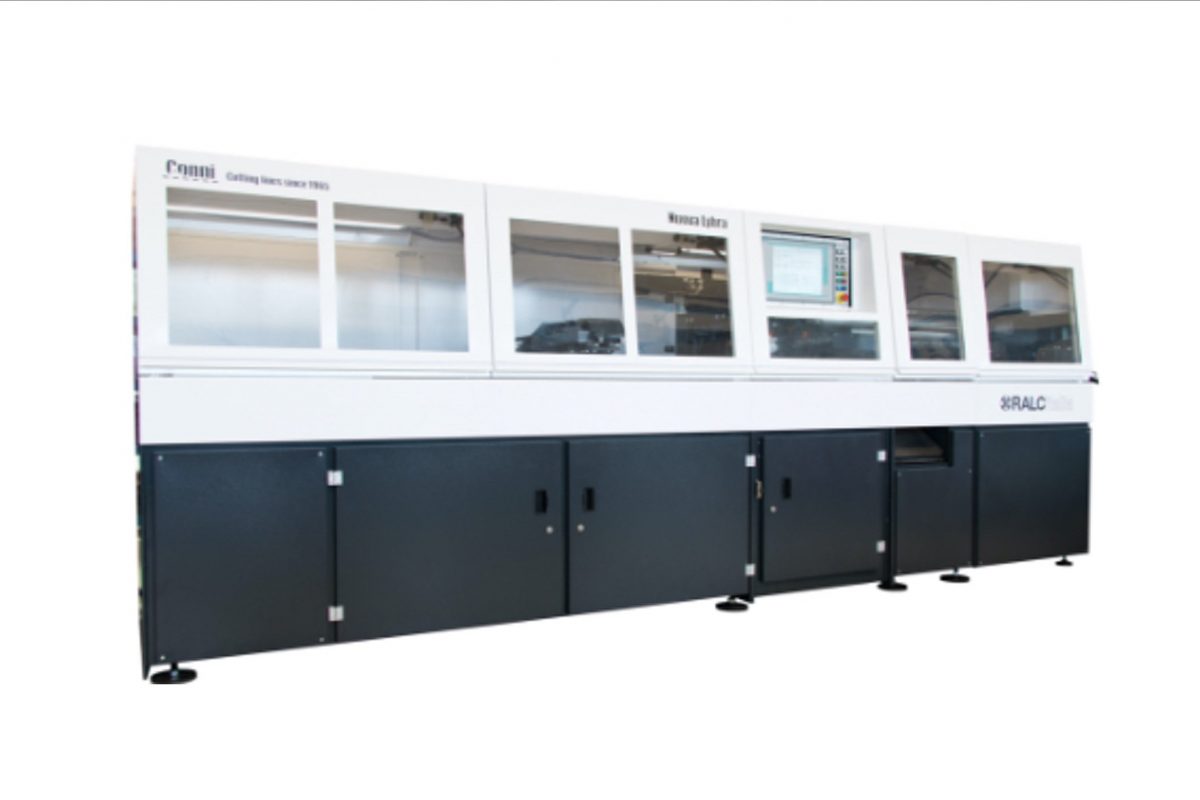

The sawing machines are available for steel, stainless steel, brass, copper and aluminium, and are suitable for cutting round, square, rectangular, hexagonal sections and all types of profiles.

We pay close attention to what the client says, offering a consultative approach aimed at identifying and proposing the solutions most suited to their project in technical, productive, and economic terms.

The modularity and variety of the offer combined with the courage and capacity to create, allow the development of ever-new, yet equally reliable systems, making the most of our experience and combining it with the search for new competitive solutions.

The result is your tailor-made system, proudly Made in Italy.

Our system is fitted with equipment allowing remote technical assistance and can be completed with a customised 4.0 package. All sawing machines have integrated stroke repetition: the client defines the length of the desired cut.

Clients can select their ideal loader based on the desired degree of automation, production volumes and the requested application. The modular structure allows definition of the minimum and maximum loading length.

All loaders are equipped with quick changeover systems without the need for re-tooling.

Can’t find the ideal solution? See the special machines section or contact us!

Ideal for small and medium production batches, can be equipped with a pre-loading system to further speed up the preparation of the material. Economical, versatile and efficient.

Designed for large batches and mass production. Loading the entire bundle guarantees the maximum autonomy of the line. Robust and versatile, it can be enriched with multiple options, which can be selected according to production needs.

Designed for the loading of bar bundles, it allows series production and high volumes with minimal input by the operator. It can be equipped with a pre-loading system to further increase the autonomy of the line.

The only loader of its kind available on the market, it allows the loading and separation of bundles of round, square and rectangular bars loaded in bundles, making unattended production possible even in extreme working conditions with a large number of different sections, always maintaining the same changeover speed.

Allows the loading and separation of bundles of special profiles, automatically orientating them when necessary for the desired cut. Unique to their kind, they minimise the necessary operator input for loading and increase the line’s unattended production time.

The ideal solution for all types of profiles, it practically and efficiently solves the problem of loading more or less irregular sections. Featuring modular depth and also usable with standard sections, it can be equipped with a pre-loading system to guarantee continuous production.

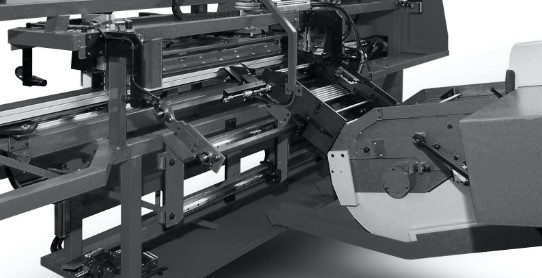

It is easy to select the ideal solution for all production needs, which can always be modulated in length to suit the client’s needs.

Economical and versatile, it allows unloading in two positions (front and back) of two or more cutting lengths.

Ideal for combined use with optimisation of the cutting lengths, it manages the separation of different length pieces up to a maximum of 12 positions (6 at the front and 6 at the back).

Perfect for simply and quickly collecting the cut pieces downstream of an unloader, deburring or washing machine. The belts progressively lower, and once the number of pieces previously set on the panel is reached, the operator simply needs to strap the bundle and unload it.

To unload pieces without damaging them, to create bundles of special sections, or for any other needs, there are also evacuation belts, special unloaders and palletizers with Cartesian axes or robots, which can be customised to suit the application. Want to know more? Contact us!