Automated pipe bender for the machining of pipes with 3D bends. Can be combined with end shaping units.

Low cost, high performance

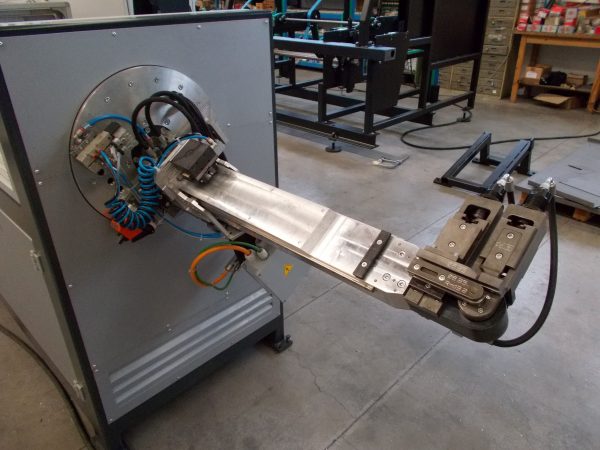

Reliable, precise, systematic, the Ralc Italia Planetaria pipe bender has compact dimensions and a sturdy, solid structure. The innovative bracing system mounted on the bending arm ensures the planes are maintained during processing; said system can be excluded when not required. Simple and fast tooling for production changeovers, an intuitive operator interface. The Planet is therefore a precious ally for day-to-day production, offering excellent value for money.

Thanks to the coil feeding system, reliability and machine concept allowing continuous, unattended production, the Planet is a high-performance line with very low labour costs. Once programmed, production is entirely autonomous and completely safe. Programming is simple, intuitive and fast.

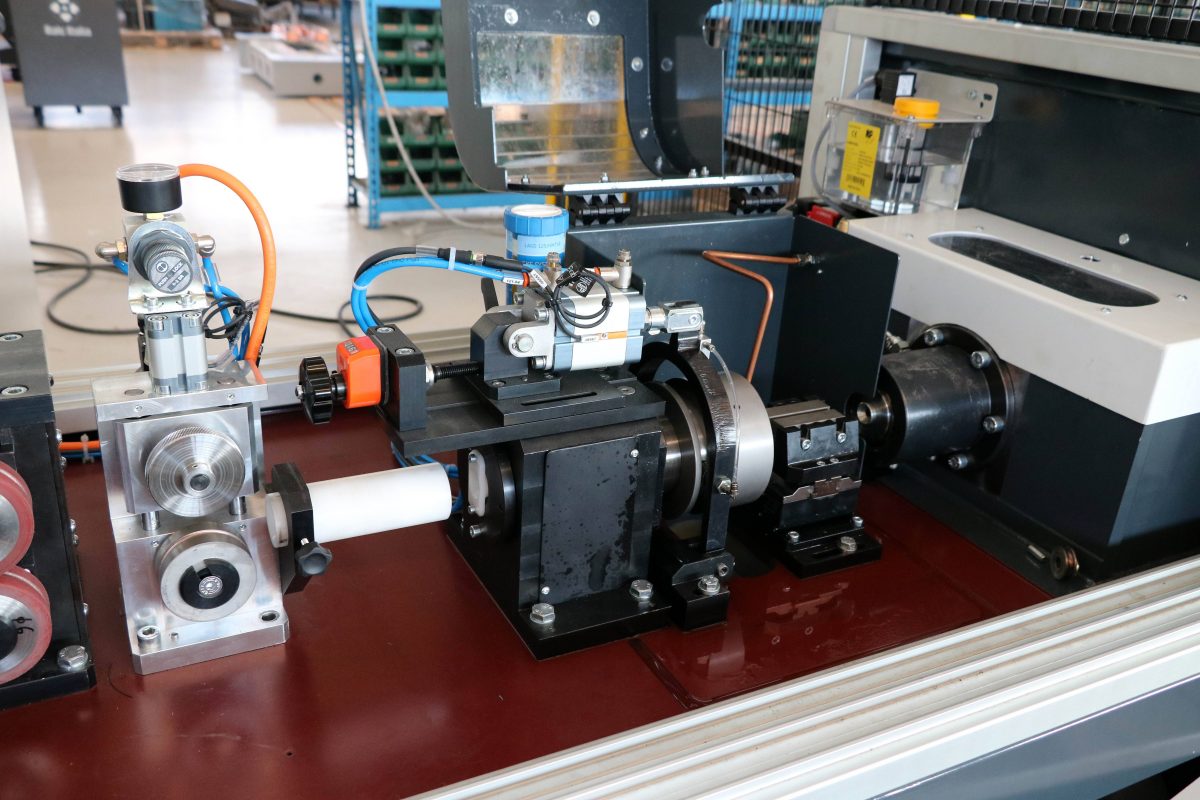

Two sets of five rolls, one on the vertical plane and one on the horizontal plane, straighten the pipe coming from the coil. The pipe is fed towards the cutting zone by three pairs of rolls driven by a brushless motor controlled by a dedicated drive, while another pair of rolls connected to an encoder determines the length of cutting, which occurs by way of an orbital pre-incision. All in fully automatic mode.

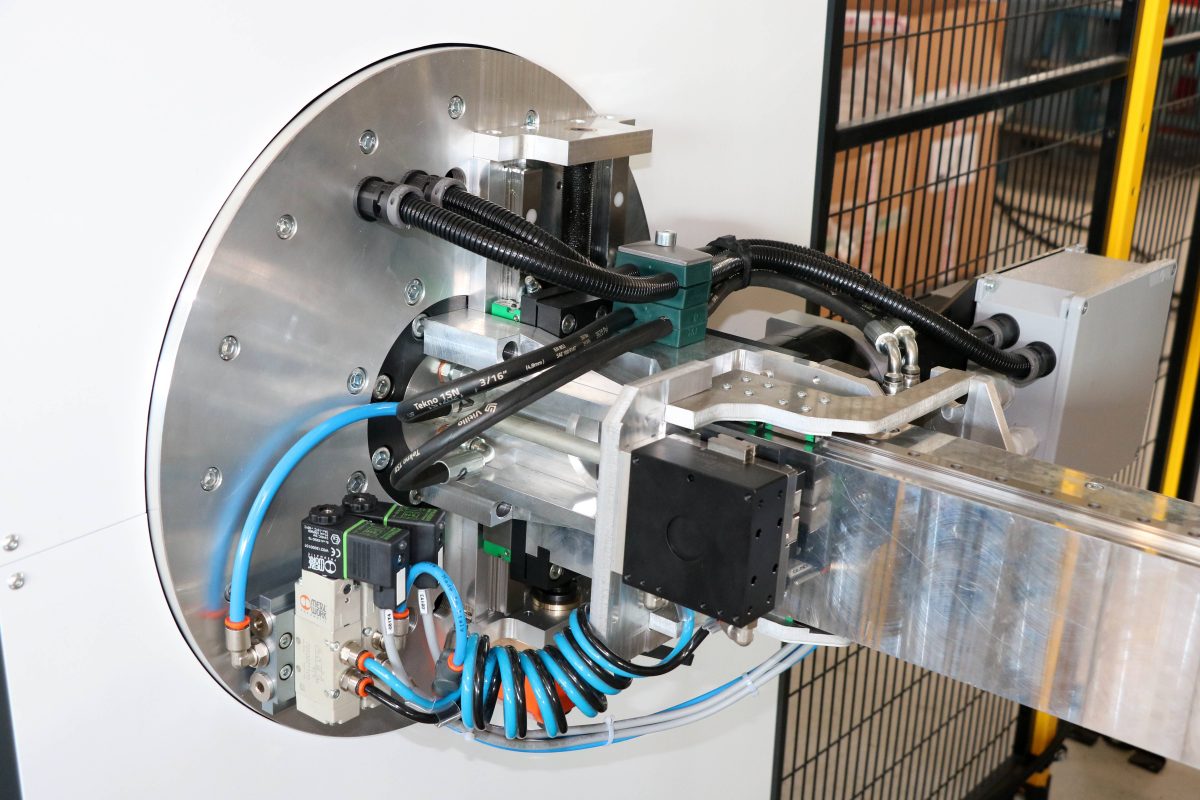

The bending unit is mounted on a controlled head that can rotate more than 360° with respect to the pipe. The innovative bracing system mounted on the bending arm consists of a gripper that guides the pipe up to the bending point. This makes it possible to perfectly maintain the feeding plane of the pipe, avoiding its rotation. The bending unit is hydraulically driven and the pipe is blocked by a clamp during its machining.

In the standard supply, the Planet is provided with all elements necessary for complete machining, but can be further enriched with options that complete the product and enhance its added value, thus making it possible to obtain different products with a single, compact, functional and flexible machine.

Round spirals are obtained thanks to the rolls mounted on the bending unit and the push-bending machining mode.

Automatically positioned by a mobile arm that places it in axis with the pipe.

The safety mechanisms are configured to allow independent use of the two machines.