Machine with one or more steps to expand, reduce, shape or close the ends of straight or bent pipes.

Stand-alone or in-line

The sturdy and solid structure consists of an arc-welded base machined with machine tools. In the stand-alone version, it works with manual loading and unloading. In the integrated version with the Planet pipe bender or cutting line, it is mounted on suitably sized guides to align the forming units with the pipe. If both ends of the pipe need to be machined, end forming transfers are available designed according to the requested application.

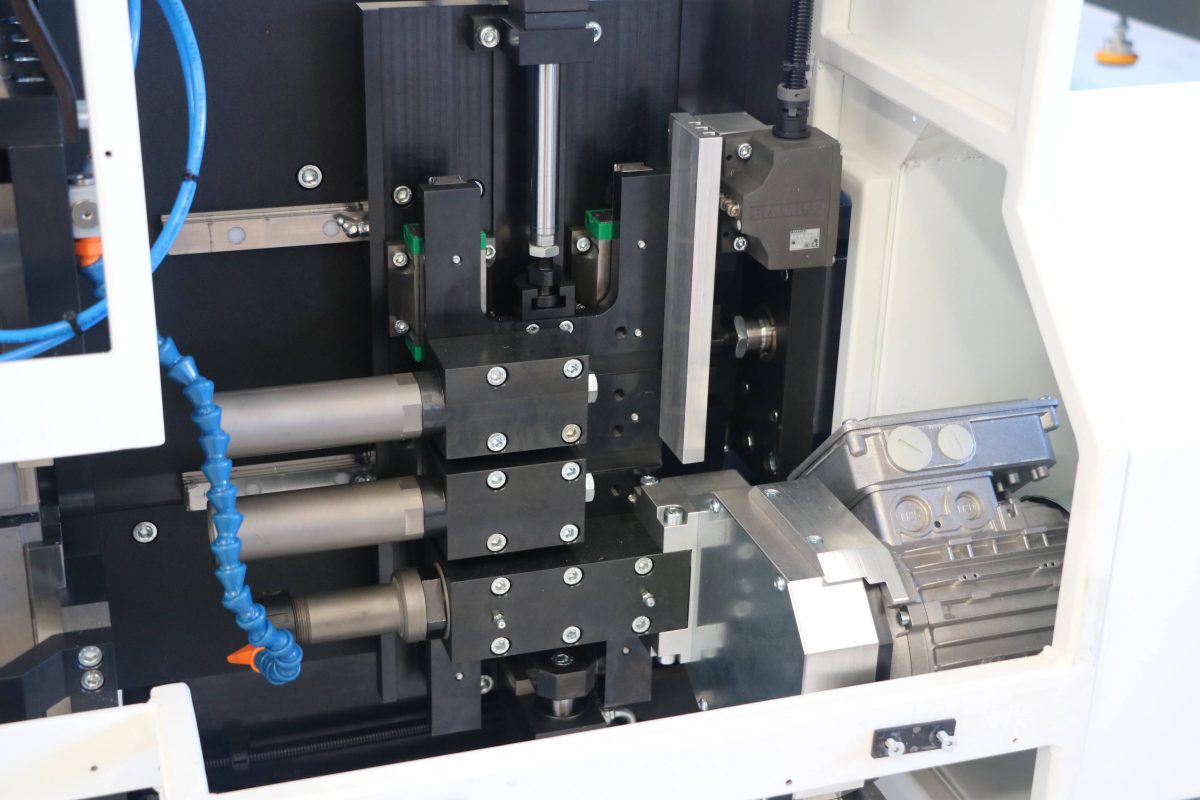

One, two, three, or six-step units are available. The tools can work in push mode, in which case the force is rated to suit the size of the pipe, its thickness and the requested shapes. Push or rotation machining is possible in the last step. In this mode the unit can be modulated according to need, ensuring the best value for money.

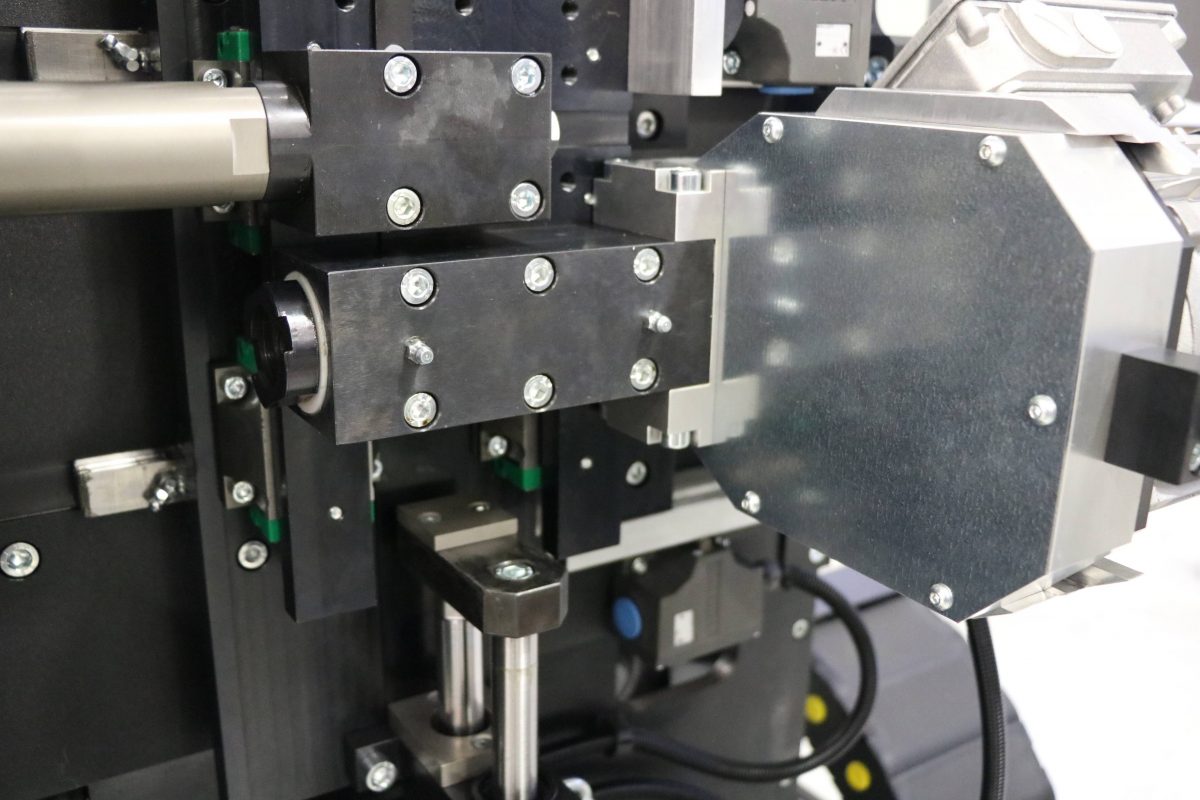

Consisting of a self-centring clamp and a vertical slide on which the end forming tools are installed. The correct vertical positioning of the slide occurs by means of a brushless motor, which aligns the tool with the pipe. When positioned, the pipe is blocked by a clamp and the tool is made to advance by means of a hydraulic linear actuator.

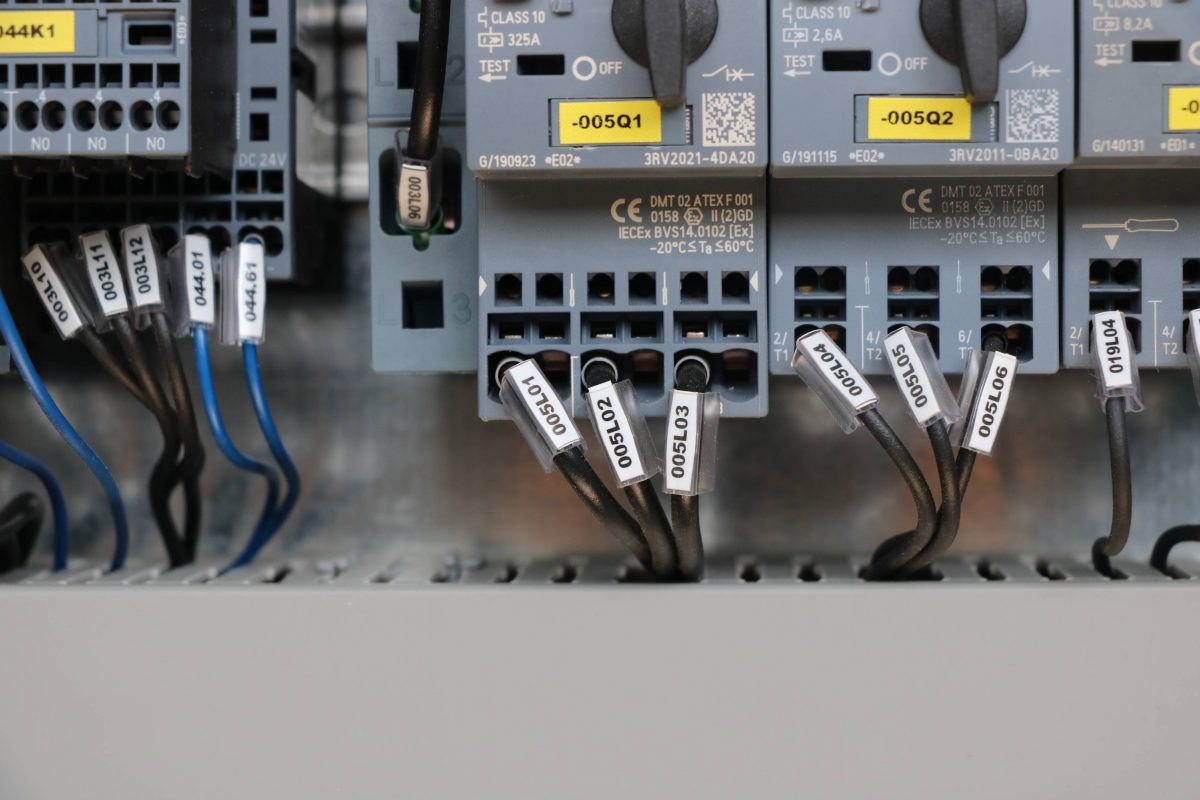

The operator uses an intuitive control panel which displays the system messages, production data and diagnostics. The power part, pilot modules and overcurrent and overload protection modules are housed inside a cabinet, complete with suitable safeguards. All of the system’s electrical/electronic components are initialled to make their referencing in the wiring diagrams supplied with the manual as clear as possible.

In the standard version, the shaping line is supplied with manual loading and unloading and is complete with the equipment and tools requested by the client; additional equipment and tools can be purchased after the sale. For complete machining and therefore to avoid any shortfalls resulting from secondary machining and handling, the end forming machines can be inserted in different types of machining cells.

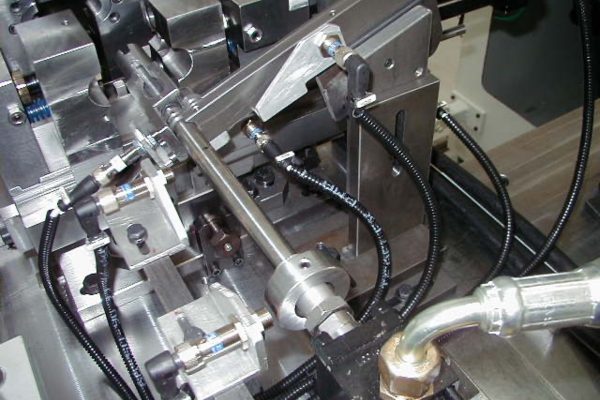

Mounted on guides, it is automatically aligned with the pipe and carries out forming before bending.

Forming is completed before the orbital cut; the pipe is then reversed and unloaded.

For particularly complex machining, or machining of both ends, transfers are available.